The base and lid in mine are for SKR Pro 1.2. If that’s your board, then you could remix mine to keep the board fit, but make the lid suitable for the other TFT holder. One note: my base and lid have a “snap in place” feature that involves slight tweaks on both those parts. If you keep the base but don’t tweak the lid, and use another lid, that snap feature won’t work. It involves bulges on one part and matching constrictions on the other part.

You should be the one to be thanked (is this correct English?) I owe you one! Many thanks from this side of the big pond! Making my photos available for you to use is the least I can do, so no problem using my photos ![]()

Printed your lid (Rainbow), looks great to me, posted Makes pics on printables, hope that helps.

Just kicked off slightly lighter version of the base, trying out mix of thin walls and thick corners/beams. Spent more time than I should have, but was determined to not let Fusion beat me.

LR3_box_Aza_skr_base_lite.zip (373.2 KB)

@azab2c Cool print! Thanks for the great pics!

Hey, I downloaded your lightened version to see what you did, and I do think there is at least a decent chance that the lightening efforts will not hinder strength in a noticeable way. When you get it printed, let me know how it feels and functions. I know if you have not printed one of full thickness you won’t have anything to compare to. The full thickness one is nice and sturdy and gives no concern about being too weak, too flexible, or breakable.

Two side notes:

First, I switched on hidden lines in S.U. Make 2017 and noticed the STL from your lightened base has quite a few “artifact” lines (somehow like auto generated by the conversion process attempting to compensate for who knows what). If you have a way to turn on hidden lines in Fusion 360 you will likely see what I mean.

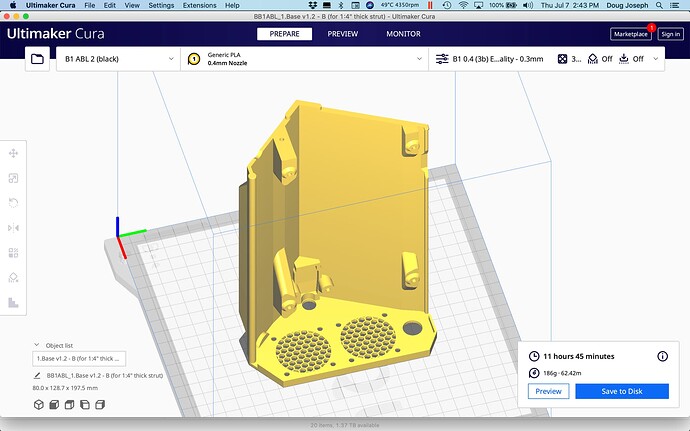

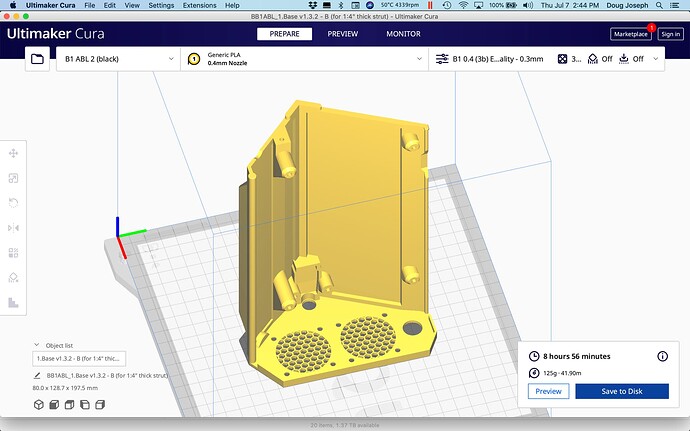

Second, I applied the same kind of lightening to my original model in S.U. Make 2017, and then ran the original and the lightened versions through the Cura slicer, with identical slice settings, and here were the resulting print estimates:

| Original | Lightened | Gain/Save | % Reduction | |

|---|---|---|---|---|

| Print time | 11h 45m | 8h 56m | 2h 49m | 24% |

| Weight | 186g | 125g | 61g | 33% |

| Length | 62.42m | 41.90m | 20.52m | 33% |

Based on this, if you report the printed lightened one still seems strong and good, I may well replace the one in the listing with a lightened one.

Notes:

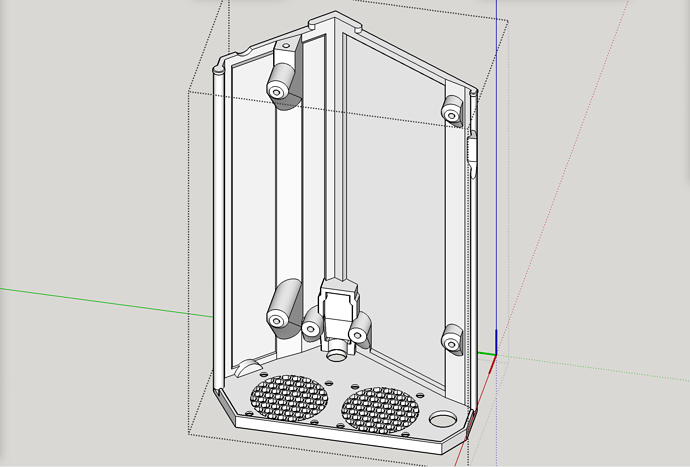

Instead of 1mm on thin walls, I went with 1.2mm. I was a bit more aggressive on the standoffs than you were. Instead of 3.x mm on the width of the thicker strips, I went with a mix of that width on horizontal, but with 5mm on verticals. I arranged my verticals slightly different from yours. See illustrations. Also attaching zip file.

Original versus lightened Base.zip (1.1 MB)

Original:

Lightened:

Hello Doug! Thank you for following up with detailed comparison on material/time.

Printed base feels and functions good to me. Slides great, with tight click at the end. Holds together really well, love tapped with hammer to release. Visually though… The transition from thick to single line Vase is visible on exterior skin, personally am ok with that since those walls face down and towards the struts.

Originally was thinking of stripping the case down to a skeleton frame and fill with sheet metal. However, kicking off prints with some thinner walls was less time consuming of my time. Honestly, I over estimated my abilities as a ~1.5yr Fusion hobbyist and spent more time faffing around in Fusion than any print time saved.

Yes, I’m blaming the artifacts on how Fusion (Free) converts STL mesh to a Fusion body that can then be manipulated. I do really appreciate Fusion, fantastic tool, but importing and manipulating meshes can be time consuming, for me.

Your lightened wall and standoff version looks great to me.

Did you consider creating a gap in the hook to allow mounting to temporary struts? Low priority, am going to see if that’s needed even. My first cuts will be LR3 struts, I can always duct/painter tape the box for that. Am not desecrating the print with a Dremel.

Woot! TFT box print just finished, time to assemble this stuff…

Thanks for the excellent feedback and photos! Your rig is looking really sharp! Love your creative color combinations. Regarding the question about the split mount bracket on the back to allow for temporary struts versus permanent struts— I had not known about that idea before your mention of it. That must not have been implemented on the generic base model that @vicious1 made available. I think your idea of just taping or Velcro to get in place temporarily until you get your final struts in place is very doable and should be no problem.

I have pried mine open with a chisel. I noticed after the second or third time the release / insert process got easier, with hold still pretty good. I chalk that up to the minor “creep” of the plastic, which I think is a documented thing.

Is that photo of the split hanging bracket one from a file I can download here on V1? If so, I can take measurements from it.

Hmm, nope, not linked in any of the docs - that I’ve been able to locate so far. Here’s the pertinent quote from the docs:

Board Boxes¶

Blank Box, DIY your own case, Fusion 360 CADlink.

Neither one of those seems to have the feature you spotted.

Didn’t see the multi strut hanging lip feature in any of the doc linked 3D model files. I only noticed the feature within couple of LR3 build doc image files…

https : // docs .v1engineering.com/img/lr3/LR3%20%2895%29.jpg

https : // docs .v1engineering.com/img/lr3/LR3%20%2896%29.jpg

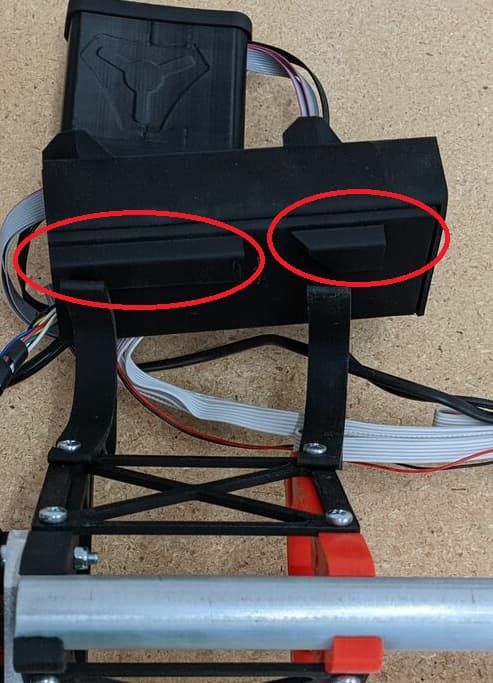

I think I may have found the model — not a V1 download. Found a model by Dan (@SupraGuy) on Printables, that seems to have that feature:

OK, I have officially released a new “low fat” version of the base with both the thinner walls and the “multi strut hanging lip feature” — all inspired by you, and of course the hanging bracket inspired by Dan @SupraGuy. I am crediting you and Dan in the release note, copied and pasted below!

UPDATE July 7, 2022 - “Low Fat” Base option

What’s this “Low Fat” thing? This is my version of a brainchild of aaron GitHub on the V1 Engineering forum. It’s a more efficient version of the base with some “fat” trimmed off. It maintains thickness and strength where needed, but saves 33% of the plastic and shaves 25% off the print time. It also has a new version of hanging bracket, inspired by the work of Dan @SupraGuy on the V1 Engineering forum. This hanging bracket is split in two so it can accommodate your temporary struts while you’re starting out with your LowRider v3, and then graduate to your permanent struts once you get them cut and installed. I’m offering both the original base (v 1.2) and the new one (1.3.2) so you get to choose. And both are available for 1/8" thick struts or ¼" thick struts.

@DougJoseph, thanks again for creating and sharing your case design.

Did you wire both Noctua Fans in parallel to Fan0, or do something else? Initially wired to Fan0 and Fan1, but Fan1 doesn’t move, guessing firmware change required maybe? I failed to find any touch/Marlin options buried in the menu options.

Appreciate space within the case, especially area underneath the controller to allow the myriad of wires to be routed. Before assembly, I thought the base and lid might be oversized. However… After assembly, I really appreciated all the space, my experience was that things are tight, but they do fit. Don’t expect to be able to coil and hide masses of wire in the box. I did everything I could to keep wiring away from crowding airspace above the processor and driver chips.

![]() I printed the parts as-is, for my regular orientation LR3… After wiring up I noticed controller box fans in your pic are facing away from the gantry. My fans face towards the work area (see pic). Then I clicked and recalled seeing you build a mirrored/reversed LR3. Wish I’d reversed the models in Cura before slicing and printing. Not a big deal, I’ve mounted the fans to suck air out of the box. Happy with my setup, will watch for issues, have a thermal camera. I know nothing about thermodynamics and air flow beyond Major Hardware edutainment, but I do appreciate some people recommend a fan be either side of the case to help push and pull air across the drivers.

I printed the parts as-is, for my regular orientation LR3… After wiring up I noticed controller box fans in your pic are facing away from the gantry. My fans face towards the work area (see pic). Then I clicked and recalled seeing you build a mirrored/reversed LR3. Wish I’d reversed the models in Cura before slicing and printing. Not a big deal, I’ve mounted the fans to suck air out of the box. Happy with my setup, will watch for issues, have a thermal camera. I know nothing about thermodynamics and air flow beyond Major Hardware edutainment, but I do appreciate some people recommend a fan be either side of the case to help push and pull air across the drivers.

Anyway, very happy with the case, cheers! Now, I need to build a table…

You are welcome! I am pleased to help.

It’s been quite a while since I wired the fans when I built my LR2. I will look for photos as evidence and if I cannot find that, I will open up my case and look. I honestly don’t remember.

Exactly my thoughts. And if you go look at people building and/or buying cases for their wiring for their CNC, the same comment is heard over and over: I ran out of room and wish I’d made it bigger. I kept that in mind while nudging the cavity open further and further.

Smart thinking on flipping your fans. In deference to the issue you just described, I will probably flip the design (base and lid) and offer it as default, and then the current one as a mirrored choice for those who are setup on the opposite end of the table like me. FYI: I was set up on opposite end of the table from the very start, even back with LR2, and long before reversing homing and switching X&Y axes. This was because of how my room is setup and how I approach the table for working.

On second thought, I think I will just add a big note on each of the listings, telling folks to mirror base and lid in their slicer if they plan to mount their box on the “left” (x-min) side of their table.

OK, I have added the following note to all the listings (original and both remixes) and will also add to the “OP” parent posts here on forum:

IMPORTANT REMINDER:

Mirror base and lid in your slicer if you plan to mount your box on the “left” (x-min) side of your LowRider v3 table. This version is designed for mounting on the “right” (x-max) side.