I have since been dubbed affectionately as the Mad Modder. I really don’t go into things determined to do mods. I seem to be very prone to customization if I think I can make something suit me better.

Aside from using unistrut so i can simplify the table build, the remainder of the build will be stock to start. First print will be the plates for the gantry, the 2nd the torsion box top so i can get it off the floor. After that, ill likely keep it as is for at least a few months.

Honestly, im nore excited for the potential of a good tolerance miter saw station and table saw bench, both tools currently sit on contractor stands which greatly limits their usability.

I think I have everything at this point. I have started assembly, however I have a couple questions:

-

is there a source for the limit switch harnesses that come pre assembled? I absolutely suck at making good crimp connections

-

are there any specs on a cable drag chain addition to the unit? ie a link to a chain, a required length, and a 3d print to attach it to the CNC?

I printed a drag chain and used an aluminium L-profile as well as @DougJoseph’s drag chain holders (which he designed for a bigger one), but still works.

For my LR3 that carries a router, I used this store bought drag chain and it worked great.

…and I designed this mount for it that worked great:

https://www.printables.com/model/223004-lowrider-3-cnc-drag-chain-mount-v10

For ease of install, crimping beats soldering. For reliability, soldering beats crimping.

For ease of removal for changes, crimping beats soldering. For reliability, soldering beats crimping.

I don’t know of any end stop switches with long wiring already attached to them, sorry.

This is only true if your crimping skills are terrible. (True for most of us, so generally true.)

But the very highest reliability stuff uses crimps oftentimes over solder.

Crimps if the connection will ever flex or bend, otherwise solder FTW (IMO)

Some folks’ solder skills are even worse than the average crimping skills.

When I was having help sessions at a community makerspace, I helped a bunch of folks fix REALLY bad solder work. Shockingly holy crap how could you think that is even acceptable bad solder work.

Added:

Or operate in high vibration environments…

I was going by my own personal experience, and I had forgotten that for purposes of avoiding high heat causing solder to soften the connection, or for flexing that could weaken solder, crimping is preferred by engineers for given situations. I stand corrected!

![]() LOL

LOL

I love to be able to swap the endstops on the LowRider without having to solder them again. Spade connectors for the win. ![]()

Yes, for where the wire meets the end stops, spade connectors. Maybe elsewhere too, but definitely there.

ah that leads me into a new question then, what length of cable is needed, and what size spades are used? Ill source new connects that are transparent so I can see if crimp is good.

I should mention: I ordered 2 of that (so 2 meters worth). I don’t remember if the need calls for more than one or I just wanted more than one.

The hardware kit from Ryan’s store includes enough wire. If you are sourcing it on your own, it’s pretty easy to buy a big spool that’s way more than enough.

Re. what size spades are used?

I bought this kit that has a variety of sizes:

OK, sorry, I have to be that guy.

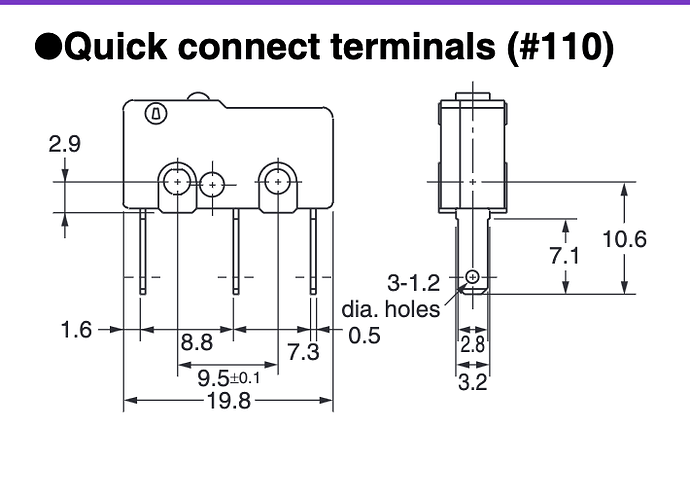

The endstop switches that Ryan sells and recommends for the machines are P/N SS-3GL13PT.

Those have a 3.2mm terminal width.

NOTHING in that kit is a correct match for these parts!

Some might fit with some effort, but I wouldn’t recommend those to anyone.

Maybe @vicious1 can weigh in with a direct link to the spade part he sells in the V1 shop for a better spec.

These work, Amazon.com

If you are looking to get wires from me let me know and I can drop some in.

I saw that info on the switch listing on amazon and couldn’t locate any crimp kits that match. I am looking to make the harnesses myself. If I have to crimp, I prefer to use a heat shrink type connection so I can see the crimp is well formed and then shrink the tube to fit the cable.

Just to say it again, if you have good solder workmanship, that works and is reliable.

If you have good crimp workmanship, that also works and is reliable.

Part of it is what your skills and abilities are.