for 10ft strut and 10ft rail, how many should I be printing?

Hello everyone, I was in the middle of printing parts to transform my LR2 into LR3 when this week I started seeing previews of LR4 (Beta). Finding out that there is a test group I like it even more. I’m going to continue using my LR2 for a few months and wait for the release of LR4. I just watched a brutal video of Jonathan at 50mm/s and 6mm DOC. Awesome. My question is the following: I want to buy some things in the V1 store like the Jackpot, some cables, temperature stickers, Tiny Touch Plate and more… I currently use arduino mega 2560 with ramps 1.4 and dual firmware but I want to change using Jackpot with the LR4 and Fusion 360 with Flyfisher post processor? I consult this since I live in Argentina and the shipping time is probably between 1 and 2 months and I prefer to advance the purchase (especially electronics). Thank you!

I got the bits and tap and die set to go this route, I don’t mind taping holes.

I went with 15 clips for now, figured I can print a 2nd batch if needed.

Next question is, is there a dust shoe that fits the recommended 1.5" hose listed on the V1 store:

https://www.amazon.com/dp/B075RZD97T?psc=1&ref=ppx_yo2ov_dt_b_product_details

This is already en route, connecting to a dust cyclone bucket and shop wen 12 gal collector

My full size LowRider v3, has its 10’ struts cut down to 114" and the EMT Y-rail is cut to match. I think I have 14 printed rail blocks in place.

Please note that there can be benefit in leaving the struts and EMT rail longer, and having the near side (front side) extend out from the table, over open air, if you attach threaded rod based clamping, so you can attach deep dimensioned items for CNC work “on their sides.” @steved did this if I am not mistaken, and I really like his setup.

All the items you mentioned (Jackpot, cables, temperature stickers, Tiny Touch Plate) should be usable with any LowRider, v2, v3, or potential future v4. ![]()

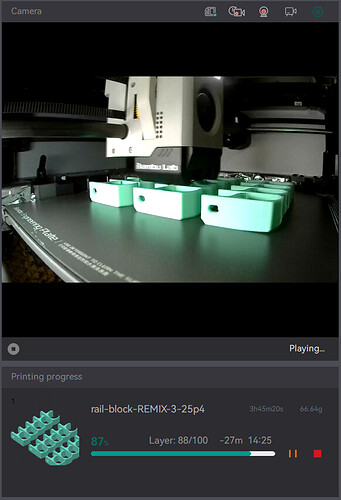

I got 15 printing right now, in about an hour ill print another 15 to have spares on hand. I stupidly cleaned the glass door during the first few layers…leading to one of them getting a little warped.

What material are you printing with?

ABS - Hatchbox mint blue, 100% infill for the EMT clips. 20% for the rail caps, 70% for anything structural. got a few rolls of that laying around.

13 of the 15 on the first print came out great, good flexibility, printing another 10, hoping to have around 20 good for the build.

end caps are printing, then ill look through the rest of the prints and mods to see what else I want printed before the parts and printed parts kit arrives.

Recommend material is PLA. ABS has a bunch of flex where pla is rigid. Will probably be ok for those parts but I wouldn’t use it for any of the other parts

I’m only printing a few of the parts, I ordered the 3d parts as part of the kit

Which part do you print?

Whenever there is a new version brewing, people get excited and start to wait. IMHO, the LRv3 is an awesome machine. And if you have a chance to build it, you shouldn’t wait. The LRv4 will be out when it’s out. But it isn’t out yet. The current version is worth building.

So far, just a few remix parts from doug. Mostly related to building the thing with unistrut

Im not waiting for the lr4 i have a big cleanup after my basement flood . Tree roots are horrid in the spring

I got one last question for you, I am assuming the 3D printed parts coming with the kit don’t include your modified dust shoe.

Is there a variant of your dust shoe that works with makita and is compatible with the 1.5" recommended hose on the main page?

I’m in the middle of making a remix of an adapter to fit Doug’s 2.5” shoe and my 40mm (ish) OD vacuum hose. I’ll post a link once it’s finished (might be a week or two, depending on how many times I screw it up).

Not that I have created, but some remixes exist that may suit the purpose, and as @Bartman mentioned:

So once he gets that posted it may help.

My thinking is the adaption point would be at the top. I don’t know if that’s the most effective conservation of suction power, but hopefully the diameter change from the top to the flex unit and down, would be OK.

Ryan will send out standard printed parts and not third party modified parts.

This means the standard dust shoe (which works with the Makita perfectly well) and standard height YZ plates, and not my taller modified ones. (Which are also not necessary for regular machine use.)

Until you have the machine working, it is highly recommended that you build bone stock standard. Modified parts always increase the difficulty of the build and the difficulty of getting build support from the forum. Doug provides great support for his modifications, and many of us also get it, but building exactly standard means everyone who has built one, modified or not can probably help you get past issues or problems. Once you have the standard build working, then consider modifications that might make it work better for you.

Things that work better for me, or for Doug might not be necessary for you, or might even hinder features that you do want to use.

Ryan makes his designs so that they are easy to build for a beginner, even if you don’t have a full working knowledge of how the complete machine functions yet. We tend to make modifications with that knowledge, and even if we try to make it simple, we focus on what we want to be different, which means assuming a level of knowledge which a beginner almost certainly does not have. At least that’s how my mods are, but I’m not monetizing a YouTube channel and am not looking to provide beginner level support for my mods.

The absolute stock build, as designed by Ryan will result in a capable machine, and will be easy to build, and easy to get good projects going. Available modifications are great once the basic machine is working if you want something that it doesn’t do.

I’ve been following along here for awhile and I don’t think I could possibly agree more with Dan’s advice to build it bone stock. I built my LowRider 7 or 8 months ago about as close to stock as it gets. Similarly, I came from using a 3D printer for a few years with limited woodworking skills. It is certainly manageable but there is a learning curve to this. It seems like everyone wants to jump into mods right away but honestly, you don’t really know what you might need yet. I’m just now to the point where I’m thinking about building a different table and incorporating some other changes. At the same time, my stock LR3 is fully capable and I don’t feel like I’m missing out on anything.

It is good advice. If I remember right, I think I built my initial LowRider v2, either plain stock or real close to plain stock. I confess I did do mods on my initial version 3, right out of the gate, but I did have my feet wet by then.