First of all. If this were ANY other place/space/forum I might be inclined to walk away with my tail between my legs and never return leaving yet another one of those threads in the internet that just stops without any final resolve. But two things prevent me from doing that.

- I just don’t do that

but more importantly

- V1E is a family and a very special one if I may say so and I appreciate that while I’m sure from this day and forevermore this will be something you all tease me about anytime I have any further problems crop up but in the end you’ll always, always go the extra mile for me (and any member of the V1 family) to help.

So here’s the sin I have to confess. Jamie - do you know what gives you a 145% ratio? The circumferential difference between the toothed pulley and the outer surface of the same pulley which, if inadvertently installed UPSIDE DOWN, the belt would happily ride on without you really being able to see because through the peekaboo hole they both look darn near the same.

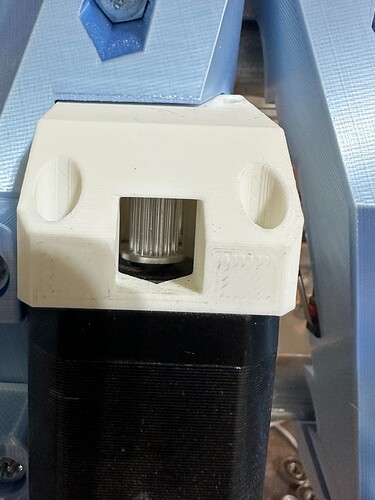

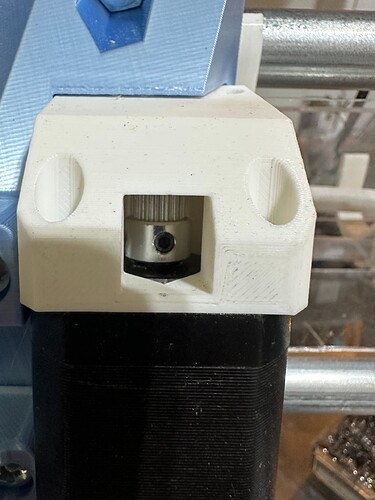

The photographic evidence/confession:

Priimary core pulley:

Secondary core pulley:

So how did it get carried over from the initial setup to the new/replacement “matched set” steppers?

I wasn’t paying attention. I had the old stepper by the new one, backed off the pulley’s grub screws, lifted it up from one shaft and dropped it on the other.

Why were they different to begin with? I built the second core from memory, not using the instructions. It’s a pretty simple component of the build really, eight bolts and washers and the x drive assembly. I never looked at the instructions at all which I’m pretty sure say something like “note orientation of the pulley”.

Now, what positives can I take away from this?

I’ve learned how amazing the clear strut plates are for verifying that the sound of a nut falling from the trap was indeed a nut falling from the trap which means you’re now going to be removing the lower bearings on the core to lift it off the rails so you can get the nut back in before reattaching the x drive. The only thing that wold make the clear strut plates better would be cutting the triangles in but in my case I want to try to keep the rail as closed off as I can to keep snow out. The clear strut plates are also amazing for those (many) times I had to rethread the X belt.

Speaking of rethreading the X belt. I’ve developed a killer technique that makes it super easy. I’m sure everyone has already also developed that skill but I like to think it’s because I’m so smart and must be the only one that has ever thought of using another belt fed the opposite direction to then mesh with and pull through the important one.

Oh! Oh! Oh! I’ve also learned how to flash the ESP and load the stuff and swap them and download them to review and post logs! That’s all very valuable learning for me too!

And not that this is a “new” learning for me but this whole adventure has certainly reaffirmed the reality that V1 is an amazing place!

Now let the razzing begin…