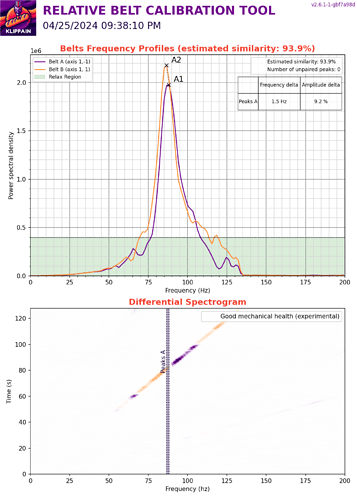

Finally made it back home yesterday and able to mess with the V5 some more. I spent almost an entire day before I left trying to get the belts to even out. Figured out after I left that I had screwed up originally tensioning them. Loosened them all up and did it right this time and they came out MUCH better…

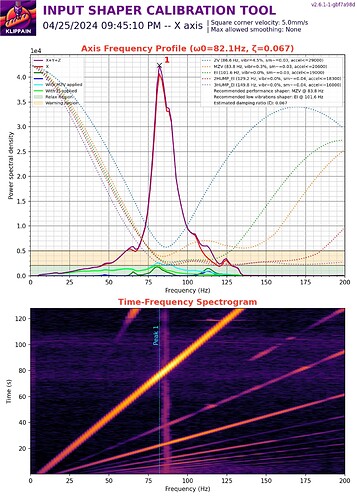

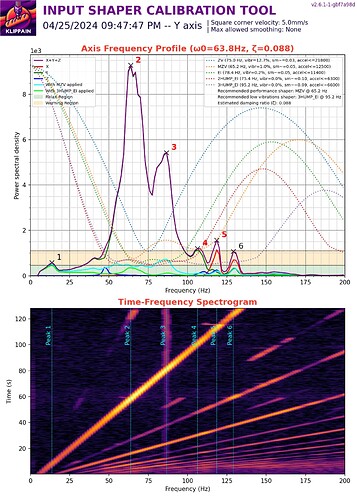

After that I ran input shaper to see how it looked…

Needless to say I am very happy with those results. Ran a print for a screen mount last night at 10k accelerations and it printed amazing! Will post a pic of that when I get it all mounted.

Right now I am trying to desolder the RJ45 connector off the M8P so I can replace it. I tripped over the wire last time home and basically ripped the connector apart lol. I much prefer having them hard wired when I can vs wifi so want to get this fixed up correctly.

Soon to come is some slide in panels for the top and front then start testing with some ABS to print the ERCF V2. Not going to be putting it on this printer but this is the closest to enclosed printer I have so I think it will be best for printing ABS