Hi @peter. The Z axis uses two lead screws driven by a belt from a single stepper. The four hardened rods sit at the corners and provide alignment, strength, and stability. The linear rails are middle of the pack (I think $30 each) and perform very nicely. Just keep them lubricated. The real cheapo stuff which you can get for around $15-20 is absolute junk you should not consider. I got some of those from a build kit a few years back and they were noisy, would bind up, and ultimately rusted out and failed.

What do you use for lubrication? I haven’t used linear rails before. I was definitely not going to lubricate them :).

I think 4 leadscrews would bind up pretty fast. If you put any rotational pressure on a leadscrew nut it will completely lock up. If you had only leadscrews to keep it aligned, it would bump something and completely freeze.

It is a similar concept to the MPCNC Z or the Low Rider Z. Those use tubing and bearings for alignment, not the leadscrew.

Every once in a while I put a drop of 3:1 on the rail near the pillow block and let the magic of motion do the rest. Rails usually have docs on what type of lubrication they like.

I’m a fan of superlube. That’s what I use on my linear rails and lead screws.

Cool.

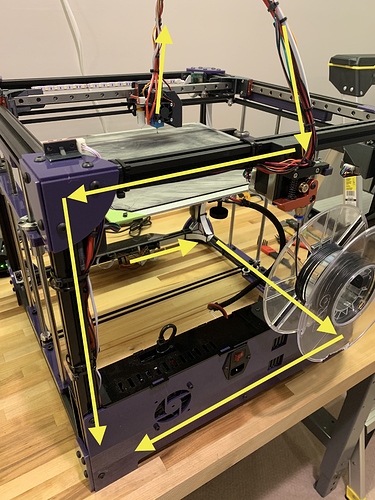

Here is an update from yesterday.

I cut a box from 1/4" cheap plywood. I was considering using some more baltic birch that I have, but the options were either 3/8" or 1/8". I must have gotten one of the CAM files confused and made the tabs on the inner part a bit big. Nothing some sandpaper and elbow grease can’t fix.

I got my bolt depot order in. I was able to finish the Z axis, under the bed. That looks really nice. I found a few more issues with the larger angle brackets I have. So I decided to just follow the BOM and get the smaller ones. Specifically, the front corners need all three swapped, instead of just one, and I am thinking the ones above the XY motors are probably too large too. There is one by the PSU that is keeping the box from sitting all the way down. The ones in the top layer mean that I can’t fit the linear rails in there.  . The angle brackets win.

. The angle brackets win.

I did manage to get the screw locations for the bed clips in the right place, so I can mount the bed next. The SKR I am planning on using is in my Low Rider (and made these cuts). So I also have to convert the LR to the grbl_esp32 board before I can pull that out.

I am going to wait until I actually have something printed to work on the raspberry pi/gridbot software.

I am actually getting pretty close, really. I have the extruder and hotend basically ready to go. I suppose I could get a head start on wiring. @stewart, do you have any tips on routing the wires from the various places to the SKR?

I’ll send some pics tomorrow. You think you’re close until the wiring starts ![]()

That is so true. I just did a bunch of wiring on my wanhao, and I made a 4x2 connector on the extruder for 2x fans and compressed 4 wires for the bl touch. The heater and thermistor had to find their own way. I am assuming these all follow the ptfe tubing. I will wait and see what yours look like.

My education was all electrical engineering not mechanical so I may be completely wrong with everything I am saying but… from my experience… four lead screws would be bad for two reasons I can think of. First lead screws are not great at side to side forces. That causes additional friction with the nut and can cause binding. That is why many printer designs the leadscrew is not constrained in any way in the x or y directions. Aka nothing to hold the top of the lead screws in place at the top of the Prusa or Ender 3 etc… So even if you had 4 lead screws you would still want to have as many linear rods or rails to carry the burden of lateral friction/forces. Second, I imagine it may be difficult to keep 4 lead screws from binding. Imagine if one of the three was a single belt tooth out of alignment with the others. It would be pulling that corner of the bed down while the other three would be pushing up. That would cause a twist in the bed that would put pressures on the T8 nuts causing more wear and tear or a binding. To solve that you would need to make sure the Lead screws are perfectly spaced so the belts are perfectly Aligned tooth for tooth. I may be overthinking it.

As for some comments on rails. I have been looking into this recently reading a lot of reviews and comments. Seems like even some of the cheap rails can be “fixed” to be perfect. Many people are saying that if you get a bad rail that seems like garbage then take it apart and clean it all. Remove all the junk grease that use. Put it back together without any line for a quick test. If it still moves poorly then order replacement ball bearings. Then assemble it again and use super lube. Then it should be good as the top quality rails. At least that is what seven other people said they did. That’s what I will be trying soon. Oh! Also only buy rails that have good reviews to begin with.

To be super clear, the GridBot has two lead screws, not four. The are spaced far apart and aligned in such a way that if they bind, you have done something terribly wrong.

On the rails … have you ever disassembled, cleaned, and reassembled one? Save yourself hours, tears, and lost ball bearings and spend the extra $10 to $15 on a good rail.

Heh, you haven’t seen my video where I break my printer and the little ball bearings go flying… To be honest, I thought the magnetic sheet would let go of the flex plate, I was wrong. Pulled the plum connector apart at the bottom of the lead screw.

@mordiev Generally there are two things that cause crunchy rails. The grooves aren’t milled properly, or the carriage isn’t built properly. Sometimes taking it apart and putting it back will get the return lines back into alignment. Generally a shitty rail is a shitty rail.

Oh wow.

Barry “bringer of fires” “Breaker of railcores” “underestimater of magnets” “beta of testers” “first of his name” 99705.

Got it. Cheap rails = bad. I just ordered a few from amazon that had good reviews. Not the hiwin type but if these suck I’ll return them.

@barry99705 how did you…? Wow! Impressive destruction video.

He is the anti crash test dummy in that so far mostly near missed but close enough to count. Still utter bedlam surrounding him

Thanks for all your answers! The binding and alignment issues with four lead screws make sense. And good to know there are good “middle of the pack” options for linear rails.

@mordiev I only lost one bearing out of that! Pretty sure it bounced above the enclosure onto the carpet. Gave me an excuse to order some ceramic bearings. They didn’t make a difference… Though the rails were pretty good to begin with. Had to epoxy one of the printed parts back together so I could print a replacement.

I have been looking at possibly building a corexy of some sort, but still pondering it. Has anyone tried the mgn12 rails from?

http://www.zyltech.com/zyltech-mgn12-h-type-linear-rail-with-single-or-double-carriage-block/

I have had very good luck with some of their other products & they quite often have sales with 10-15% off.

these are the same rails I used in the GridBot, just got them off Amazon instead

I think the general consensus is hiwin, misumi, ldo or zyltech. Cheap ones off ali are a crapshoot. Some are okay, some are junk. No, or light preload if possible. I’m pretty sure mine are zyltech.

FYI. I know my way around an SKR board, and the electronics of my printers, so I’m just curious about how you fit the wires around, and if there are any places where you added connectors or routes that would help me with writers wiring block.

I have freed the SKR from the Low Rider. I have the Grbl_ESP32 installed there now. They apparently have a version 1.2 out now, and I have a 1.0. During testing, I attached it to the Z of the gridbot. It moved.

I should be getting the new corner blocks today. I am focusing on getting the electronics box finished. The cover (in this cheap 1/4" plywood) has a little twist to it. So I printed up a bracket for the side that doesn’t get held down by the power supply. I am also hoping to fit in a SSR for the bed, so I can play with PID bed heating. I am going to just drill those holes by hand, but I want to dry fit everything first, to make sure I have room (I’m shooting for above the DCDC converter, but I suspect I need to be careful with the AC that is right about there).