Oh that sucks. Last year a nasty wind came through and blew over sooo many fences, it split my tree in half. Hopefully it is an easy fix not a complete rebuild.

Our fence has been over the replacement line for maybe 5-10 years. We need to replace it, but my neighbor isn’t liking the prices right now. They want to do manual patch work.

I need to replace the whole thing, but I need it to not fall over in the meantime.

Lumber prices still crazy down there? Out local Agent Orange is still asking small fortunes for wood of most descriptions, but some smaller places the prices are getting more reasonable lately. Still really high, but I don’t know that it’s going to get better in a timeframe that I can put off fixing my deck…

The print quality on that case looks amazing. I get impatient and start with the really chunky layers. I’m still happy with my Duet case.

I think most of our lumber comes from up there. So it will have to cool off in Canada first.

Even our furniture is made in China from trees in Canada.

I haven’t actually got any quotes. That’s on my list.

It is alive!

One Z motor was spinning the wrong way. I swapped some pins.

Now it can move X734, Y1240, Z82. And it moves pretty smoothly.

I am very happy with this version. It has a lot to love about it. I didn’t try the v2. But this seems like a big step up in many ways from LRv1.

Next up:

I want to design a DC power distribution box for the front, under the lip where the old LR was driving. I need:

5VDC for the pi

12VDC for the laser

24VDC for the skr (I know, it doesn’t matter, but I have used a 24V for a while).

I also want to plug in the router on the front. But I am thinking I will just attach a power strip for that.

The pi’s SD card is also hard to reach now. I can use raspi-config to allow booting from a USB. So I am going to try to boot from a micro SD card reader. Then I can put the SD in the USB port where I can see it.

Given all of that, I think I know what edits I want to make to the case, and they are minimal. Just a little extra room in a few places. So I will get to cutting and printing that.

I also have to determine what I will do for dust collection and DC static reduction. I want to try to use a larger 2.5" hung from the ceiling. Similar to what Barry has done in the past.

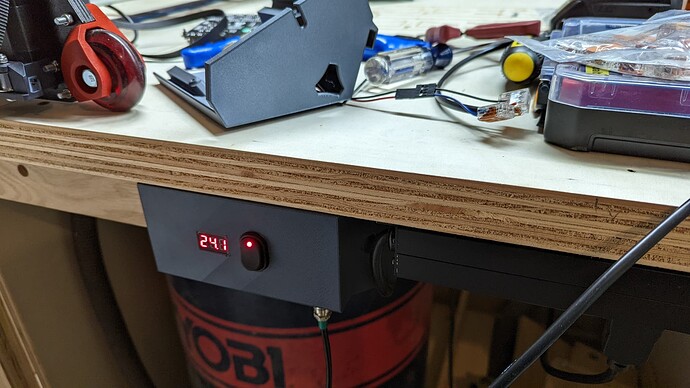

I built a nice little power box for it. This area was previously taken up by the LR1 parts. But it is free to use now that the gantry is all on the table.

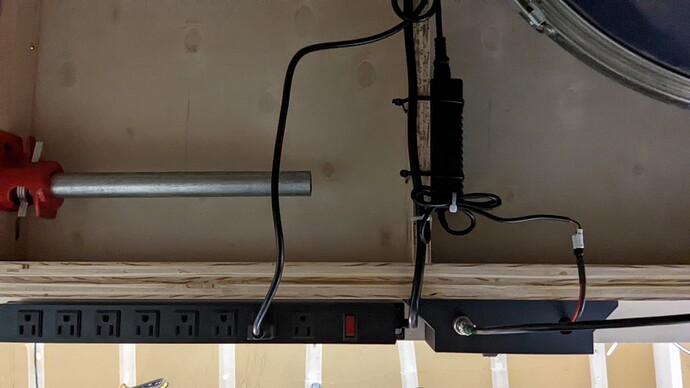

The right side is a commercial 120VAC power strip. I will plug the router in there and it will be my estop as well. This has a 10 foot cord and reaches the wall and then some. I don’t plan on hooking the dust collection to this. But I bet it would be fine. I have a bunch of extra ports for the air compressor and the laser PSU, or whatever I will use the table for when it isn’t a CNC table.

The left side is a box with a little power meter, a power supply for the pi, a switch to kill power to just the skr/motors, and a nice little cable disconnect so I can remove the LR.

This is what is inside the box. I am using wagu connectors. They seem pretty nice. Very flexible compared to crimps and they can deliver a lot more current.

A pic of the underside of the table. I have a vertical support made from 3/4" plywood right there. So I just drilled some holes and ran some zip ties through to attach the PSU and the cables.

The box and the power strip are held with wood screws (1" #6, they aren’t going anywhere).

Quickly becoming a favorite for me!

That looks so good tucked under the lip, classy even.

That toggle switch is actually pretty deep, with the spade connectors sticking out the back. So it is just slightly proud. I could add some trim if I cared.

I didn’t post a shot of it on. Oops.

I mostly like that I can turn off power to the skr without killing the pi. I am just sitting here testing the that the pi goes on before I reinstall the skr board over it. I also have edited your step file to embiggen it. I think it is going to be the “final” one.

I might actually have to make some kind of guard for that switch so I don’t accidentally trip it.

Oh my goodness!!! I am doing black side plates for sure. That looks soo good. So freaking good.

I like the braces. I think I will sell them as the ends a separate color to show they are higher infill, and the red core…love it.

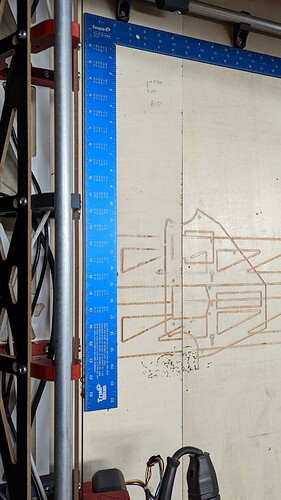

I use my big blue square to set the starting location (still no digital endstops for me). I drew the corners and X was 702 (should have been 700, nut the marker isn’t perfect) Y was 800. The diagonal should be 1064 and it was 1063. It is hard to tell from the marker marks. But I measured before I calculated so I wouldn’t be biased.

That’s pretty good for woodworking, IMHO. It is very good for an eyeball, a big square and a marker.

I guess I have to get it dirty now.

This is what I’m doing to start it. The blue square is against those rail holders. Then I look for a consistent gap between the machine and the other edge with my eye.

Dang that sighting is pretty good. That belt should be very straight.

You know what thought just occurred to me…all we need to do is use the top (print orientation) of the braces to get rid of a lot of the bed warp issues. I am printing them two at a time so I need to see if I can fit two like that.

Would pledge work?

Sorry need to get better at quoting. The chalkboard. If you put pledge on it wouldnt it do the job?

Yeah, probably. That is a good idea.

Awesome build.

I just started-

Planning on royal blue, black and space gray.

Question about the strut- would it be possible

To print one of the temporary strut plates, and use that as a router template with a flush cut bit to make the strut? I’d just need to mark locations for holes etc but that’s easy in terms of woodworking prowess needed.

Thanks?

If you take a look at the DXF or CAD I think it would be easier to just do it by hand no need for a template. 80mm tall, as long as you need, holes evenly spaced starting and ending 7.1mm from the end. Be careful with the holes, the alignment will dictate the shape of your beam, I highly suggest whipping up a quick drilling jig to get them right. Or just using the machine to do it all for you.