Just having a play with the schematic now. I was going to PM this but might be nice to chuck this stuff out in the open so people can follow along if they like.

Extra unexpected connections:

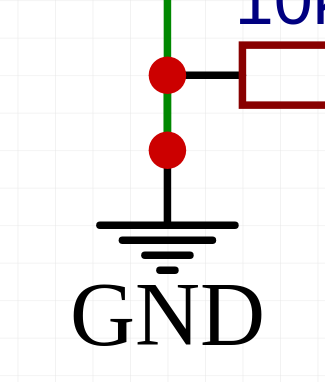

One thing to look out for is when you see things like this:

The red circle means it’s an intersection between at least 3 wires/nodes. Given that there’s only a wire and the power port there, that means there’s a 2nd wire sitting on top of the other wire. It’s usually not an issue, but I find it helps to spot that and fix it as soon as it happens, rather than have it make a mess when you drag something and it splits it into a bunch of different wires.

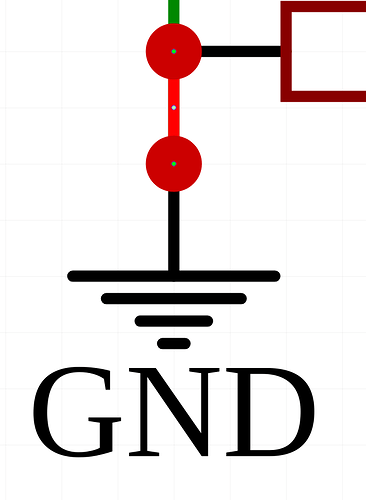

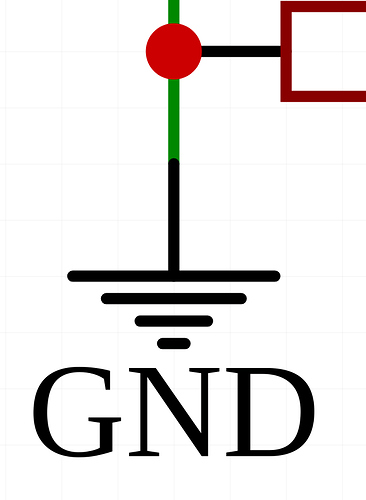

In this case, it’s just a stub between the resistor pin and the power port:

And deleting it brings it back to what you’d expect, which is red junction indicator on the resistor pin because it’s going to 2 wires, no junction on the power port because it’s just wire to port.

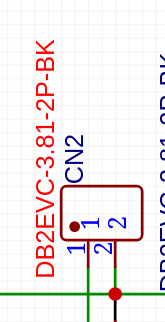

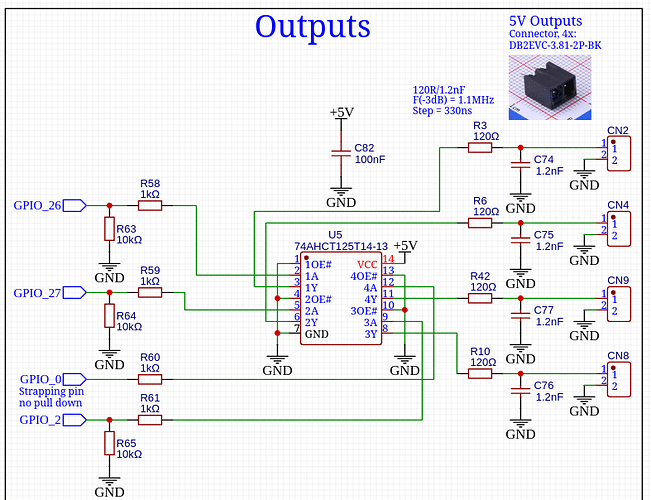

Long part numbers/connector info:

With excessively long part numbers like that I’ll often hide them and then do something like put a note/photo of the part next to them. If you need the exact part number, the BOM is where that should be taken from. If you need the rough part for review, a photo is often a better option than a part number, etc.

Dropping a note like that somewhere nearby makes life a bit easier.

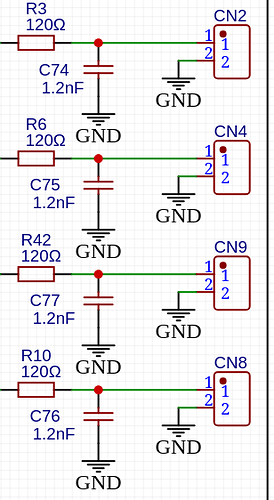

Repeated schematic snippets:

When you’ve got repeating parts of a schematic that are the same or similar, I like trying to lay them out the same and have them near one another. That way it’s super easy at a glance to see that they’re all the same or spot any differences.

Wiring between power ports:

As above, I also prefer to just use multiple power ports/GND symbols rather than wiring between them. If you want to move the connector, it just goes with it. You don’t really need to know that pin 2 of the connector is connected to the bottom pin on that capacitor, it’s not specifically useful information beyond knowing that they’re both at 0V for their function.

Designator/value location:

Don’t worry about moving the designator and value text if it makes the schematic cleaner. As long as it’s clear which component it’s for and the designator and value are together then it’s usually fine. Conversely, if they don’t need to be moved, keeping them in the same kind of location for the same type/orientation of components makes life easier. IC part numbers and designators above the IC. 2-pin passives (resistors, inductors, capacitors) that are horizontal having the text above or that are vertical having the text to the right, etc.

Schematic flow:

I generally try to keep everything flowing left to right for ‘signal’ flow and top to bottom for ‘power’ flow. A lot of this is personal preference, but that personal preference is informed by having spent a lot of time looking at other people’s schematics and having an innate sense of what is most common and ‘preferred’, admittedly with a very western/european perspective. That’s not a hard and fast rule so sometimes a clean schematic that flows in an unexpected direction is better than forcing the flow to be ‘correct’ at the expense of readability, but the goal should be to try keep it clean AND flowing as expected.

In this case I’ve also kept it so that the top GPIO connection flows through to the top output connector. I’d still usually put a note at the connector symbol confirming what it’s purpose is or what GPIO is driving it, etc.

General schematic hygiene:

Don’t be afraid to move components and change the schematic layout to give more space for things or to make text info easier to read or more obvious. The whole point of the schematic is to provide an easy visual representation of how the circuit is configured so that the layout is easier to get right. Having all the connections be correct is the main thing, of course, but the secondary aspect of that is having it be easy to read so that it’s easy to visually verify that the connections are correct. A technically correct but ‘ugly’ or confusing schematic is fine, it’s just a lot more mental effort to verify that it’s technically correct and has higher likelihood of not being correct as a result.

Also don’t be afraid to split into multiple sheets, especially when you’ve already got a really nice functional block layout like you’re using. Having a sheet that’s just ‘IO’ and has the inputs/outputs on it is a great way to do it, for instance. Multiple sheets can be slightly harder to work with, but the benefit of having more space to lay things out clearly and cleanly can offset that and then some. When crossing sheets I would try to make the net or port naming as clear as possible to avoid needing to refer to multiple sheets at the same time. I would also try to keep as much of the circuit as I can on one single sheet. As an example, with the IO blocks I would try to make sure that the IO sheet has everything that GPIO_26 is driving and all the components it’s connected to. The sheet that has the microcontroller on it would then just have the micro with the GPIO_26 port/net label and nothing else. There are some exceptions to that such as when parts connected to the same part of the circuit have wildly different purposes. Bootstrap resistors are one example, I’d usually put those with the microcontroller so that they’re readily visible when reviewing the schematic to make sure that the microcontroller is wired up correctly. I might put a note on the IO schematic saying ‘pulldown on other sheet’ or similar. On the other hand if all they’re doing is acting as a pull-down to make sure the output stays off while the microcontroller boots then I’d put that on the IO sheet and, if it’s important for the microcontroller review, add a note near the microcontroller saying that the pin is pulled-down on another sheet. Again, no absolute right or wrong but thinking about it from ‘what makes the most sense when reviewing the schematic to make sure it’s wired up correctly’ is generally a good start.

Other notes:

Every IC should have a 100nF capacitor placed close to its Vcc pin if just using a ground plane or nearby if using a ground and +V plane. I always put that 100nF capacitor next to the IC on the schematic which ensures that it doesn’t get forgotten. Technically it doesn’t need to be that exact capacitor for that exact IC but it’s good practice to get the details like that right. If it doesn’t end up mattering, it’s just a couple seconds extra time that was taken. If it does end up mattering it might save a few minutes of confusion or worse.

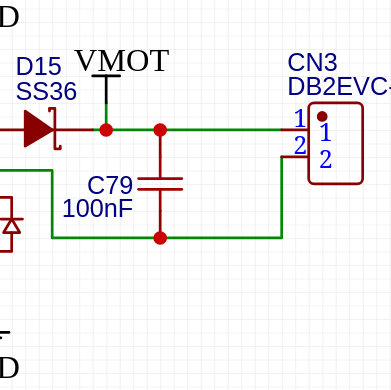

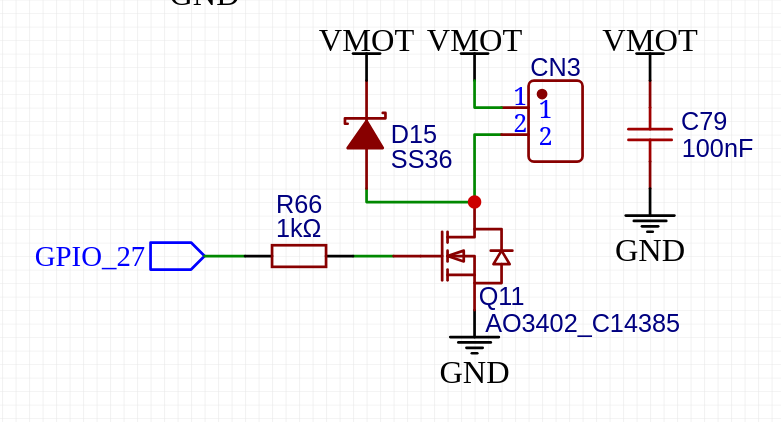

I think I might have confused you a bit here. When we add decoupling capacitors, we do that so that any inrush current or high pulses of current that occur can be supplied by a capacitor as near to the load as possible. That saves the current coming from a different part of the circuit potentially causing a voltage drop elsewhere or letting that ‘noise’ that’s generated interact with other parts of the circuit.

In this case, the capacitor is added such that it’s across the load and will supply the any current pulses while the circuit is operating, but it’s also being switched by the FET so that when you first turn on the load it will also have to be charged by the FET. Because of that it won’t help with any inrush current (such as if the load has its own capacitors on its input) and will in fact lead to more inrush because you’ve got another capacitor to charge.

This is how I would lay that out. The logic for the current flow is that when the output is off there’s no current flow out of the connector. When the output turns on, there may be a pulse of current out as the capacitors in the load charge, for example if it’s controlling a SMPS, motor controller etc. So a brief burst of high current has to come from somewhere. Having C79 there means this current pulse will flow out of the ‘top’ pin of C79, into pin 1 of CN3, through the load, back through pin 2 of CN3, through the drain of Q11, out the source of Q11 and then finally back into the bottom pin of C79. If you don’t have that capacitor there, the current still has to come from somewhere, but that somewhere might not be anywhere near CN3/Q11 and it can be difficult to predict where and what the effect might be on other parts of the circuit.