Hmm… 0 where stepper connects to extruder housing, maybe they planned for stepper being swapped out or changing over time? ![]()

Slightly different body and nozzle distance for BIQU H2 V2S REVO vs regular H2…

Hmm… 0 where stepper connects to extruder housing, maybe they planned for stepper being swapped out or changing over time? ![]()

Slightly different body and nozzle distance for BIQU H2 V2S REVO vs regular H2…

The bottom view is just as bad…this thing is so random.

Ohhhhh, yeah it can get tight, but it is not too bad. Once I get the h2 mocked up I will commit to a endstop location.

it gets set in the firmware so you can’t screw it up…but I prefer to home both simultaneously, so that is why it goes on the core (or the truck)

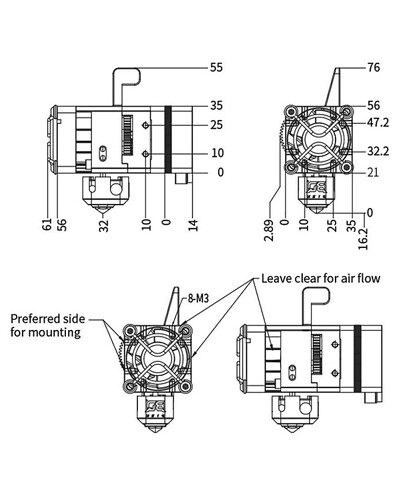

OMG…the drawings for the two are completely different. WTF. The revo is worse, How do you measure from a 0.4mm hole off plane to anything. These have to be the the worst drawings I have seen in a very long time.

I am going to mock up one H2, if you get a different one slight adjustments will need to be made, but not by much.

I just need to get two in there so I can figure out how to make the bed location parametric to a feature that is so far in the future. I have an idea but I need a couple in there first.

Almost forgot still need the belt ptfe spacer holderer

I have the H2V2S and the side with the gear sticking out where it says this is preferred for mounting… isn’t. It works for holding a fan, but the truck mount: on the opposite side. The threads are shallow (I think I used a 6 mm M3 with a printed part to hold the fan on. The 8mm screws bottom out. I’d say they are tapped like 3-4 mm deep… maybe 5 mm. there are 2 holes on the top, on the back, and on the bottom next to the stepper that are preferred for mounting… if that helps. I can get you measurements for offset on any of it if that helps.

Yeah the manual is even worse. I noticed that error. I think they are looking through the back in the drawing and did not realize it.

It is the worst.

Thank you, I have a couple here. I know some of the holes are super deep, some are shallow.

I have already made the mount, with top and bottom screw locations. (flipped the printing orientation) I also made both belt screw holes look symmetric, and smaller.

Doing the bed equations now.

But, it doesn’t. What if I’m in octoprint and I choose to just home one axis? If, say, you can’t home Y safely without homing X first… I’ll break it. ![]()

… And all this time I thought it was only me that thought these drawings were weird…

So that one truck insert piece is ~$23 each printed in stainless or aluminum. MFJ nylon is good to up to 175C and is ~$6 each. Have not checked the core yet.

Man we can make a frigging beast like that a couple MFJ Nylon parts.

Aza, if you are planning on doing a 80C+ enclosed super collider edition, I bet that ~$12 would be worth it.

Heck, Yeah!

Man now you have me wondering if I can print nylon lol. Can’t be THAT hard lol. I don’t plan for that much heat but now I’m just curious lol

Edit…. Never mind just figured out what the MJF part stood for. Definitely not set up for that lol

You can print nylon FDM, the issue is it needs to be printed from a sealed container, it is crazy hygroscopic. Other than that I don’t think it is all that crazy in terms of temp or anything else. It is about the same rigidity as PLA just way higher temp resistance.

PC is the one I would shoot for. Not really sure why everyone goes for ASA, I think PC is the “dream” material. Maybe there is something I am missing.

I don’t remember why, but I chose ASA over PC for some reason. I’d have to go look up the specs on the PC again to remember why.

I chose it because everything I saw it was just like printing pla just hotter. Now a lot of things I’m seeing say ABS+ is real easy to print. Haven’t done any research on PC before but guess I will look into it tonight lol.

From what I’ve read, PC is a lot harder to print.

Requires higher temperatures(250-300ºC). A lot more prone to warping and delamination than ABS/ASA

This one says it doesn’t need a heated chamber and also cooler bed than pla…

But I have no idea if that blend will be good for the parts we are messing with or not. That’s all above my pay grade lol

You’re thinking of making a MultiJet Fusion for less than the $100k - $200k than they normally cost?

If they charge per part, then would ‘paneling’ multiple parts that can be easily snapped separately help reduce overall cost? Just like Airfix kits.

The print houses do all the nesting. Parts are pretty reasonable in my opinion. JLCPCB has a lot of options and is a few bucks cheaper.

Is there anything to be gained by going with those parts other than the high ass temp rating? Are they stronger? Or if we are planning non enclosed or at least not hot as the sun enclosed (60°c~) is there any advantage to having them printed there vs printing ourselves out of pla/petg/abs/asa/ect…

I went ahead and chose to be an object lesson for my kids. 0.0 for my first semester. At $7k+ in '86 for Carnegie-Mellon. *shrug* Found out about SCA, girls, and what it’s like to not have a parent working at your place of education. Didn’t end up with a degree until '98, and two state universities later.

So, object lesson… My son is in first year of Pharmacy school, after two years of an honors program that will have him graduating with his PharmD in a total of 6 years. I think he got one B those first two years, and that was organic chem (fluid dynamics would be the engineering analogue for that class). He’s learning to accept his B’s with grace now that he’s in what’s effectively grad school. The youngest, though… They work hard, and is smart as all get out, but doesn’t have the same 'tism-driven need to excel that their brother has. But they’ll do fine; they aren’t a complete slacker like their old man. Mom gave both of them good work ethics (in spite of my efforts to the contrary ![]() ).

).

I think of it like this, if you used paracord instead of string for a balloon does it help? Yes they are stronger, but if you never reach the limits it doesn’t matter.

We currently only have the inner truck part, there is not much plastic in between the screws to actually fail.

With that said, we will have to see how hard we can push things. Maybe we do break the plastic part…That would actually be kinda cool.

The core, could have a bit more to be gained depending on how much you are going to hang on it…but I also have not finished that so maybe it gets a bit more redesign. (second part is nearly done).

For me it is really hard. I know the corners, basically can not get better. So that only leaves two parts…I do not think there is anything to be gained, but for a few bucks we can have some super crazy parts.

Now the next question is would FDM PC be worth it…Not sure. If I enclose this one I will surely give it a shot, just to do it.

So, in summary, I doubt it but it would be cool!