Well I’ve continue to work on enhancing the Flyfisher604 post processor (PP) for F360.

A new beta is now available, release v1.beta1. This supersedes the v1 release that occurred a week ago.

Release History

----- Github tag: v1.beta1 -----

- Select the firmware dialect as a property

- Coolant bug resolved so coolant logic is no longer inverted

- Coolant properties are unified to control either Marlin and Grbl firmware

- Warnings if tool’s requested coolant is not configured on a channel

- Single file reduces the complexity of installation

- Installs without error via F360 standard Manage->Post Library install interface

- Properties enabling features are list before feature control properties

- Properties are listed in GCode for easy reference (more to come)

- Updated documentation

----- Github tag: v1 -----

- G0 Rapid move at the beginning of each cut is restored - resolves tool drag when Z is not retracted before horizontal travel occurs (F360 Hobby issue)

- Recovers G0 Rapids that occur above a safe height or that are vertical only (F360 Hobby issue)

- Feedrates can be scaled to ensure mpcnc Z axis cut rate is not exceeded. Fusion 360 kinematics do not respect an axes feedrate if different from the machine’s generalized feedrate.

Warnings:

- The properties for v1.beta1 have been reorganized and in cases renamed, please review carefully and consult the documentation.

- Defaults have been selected to generally disable features so they may be selectively enabled. Review properties carefully and enable what is needed. Feedrate scaling and GO Rapid recovery require properties to be enabled and are not enabled by default.

- This code is considered beta and the user must review all GCode produced to ensure it is appropriate for their needs.

Documentation for the v1.beta1 can be located here.

Here is a copy of Flyfisher604 v1.beta1

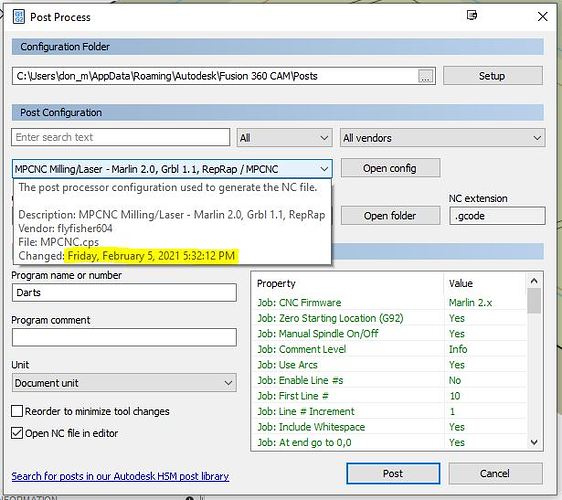

MPCNC.zip (12.9 KB)Once unzipped, mpcnc.cps can be installed using F360 Manage->Post Library. When running the PP use the Setup button to select Use Personal Post Library (will be remembered - required once).

Please report any issues to flyfisher604/mpcnc_post_processor Issues.

The files using const=1 do have 12 more g0 replacements vs 1b5 w/ retract, but this is expected. They are 12 very short downward travels, which reflect the difference between using 2.54 and 1. I think sticking with internal definitions is best, and makes the workflow easier. I would just set retract to 1 in f360 if I wanted to speed it up from what 2.54 does.

The files using const=1 do have 12 more g0 replacements vs 1b5 w/ retract, but this is expected. They are 12 very short downward travels, which reflect the difference between using 2.54 and 1. I think sticking with internal definitions is best, and makes the workflow easier. I would just set retract to 1 in f360 if I wanted to speed it up from what 2.54 does.