This is really cool!

How do you compare this vs. a touch screen?

This is really cool!

How do you compare this vs. a touch screen?

Don’t know yet, getting the dreaded N/C

Did you update your main board to 3.7.13? It’s required.

yep

because I’m a chicken I flashed a second board in case I messed up

update: on the basis that if the config is as is should be it must be physical I replaced the wago connectors and now its working!

tested homing, jogging, probing and running a file and all good.

Awesome! My next question was going to be had you edited your .YAML file accordingly. But it sounds like you did. Glad you got it working!

It actually is a touchscreen, although it is a small round one. But it’s not just a touch screen, there’s also the rotary dial, which is an input, and the two momentary switches, which are inputs.

It is a pendant, so it is not meant to completely replace the main control screen, which would be presumably the web user interface on a tablet or phone. However, while it doesn’t do everything, it does most of the common routine tasks. You can home, jog, zero at a workspace origin, probe to material height, browse and launch G-code cut jobs, turn mist and flood on and off, turn VMot’s on and off, and because you can run G-code, you can create a subfolder on your SD card, called Macros, and name the G-code files in it for your various macros, and use this as a way to run macros. The primary thing that it does not do is: no terminal interface for manually typing in commands. There may be other things that the full user interface can do that it can’t, but the terminal is the main thing I can think of right now.

Now, as I say in my recent video, “you need a cradle.“ I humbly offer my design! ![]()

Good job Doug! I saw on printables that you have done a lot of great models.

Would you use the cradle for the MPCNC as well?

EDIT: If yes, where would be the best “place” to place it?

It definitely could be used for the MPCNC, and you would just have to figure out based on your situation whether you already have a place to put it, or you need to add a place.

It is designed to be mounted to any vertical place. However, it could be pretty easily remixed to be mounted to a horizontal place as well. If that would help with mounting it, let me know.

I did mine like that a while too!

With that “loop” at the top, obviously any nail or small decorative “hook” could be used. (I’m envisioning a hook like the type some people hang their keys on)(and sorry, watching lightly, I never noticed that “loop” until just now)

As far as the MPCNC, the cradle could always use the vertical side of the MPCNC table, depending on table design, like some people have used for the screen or controller box in the past.

My only personal issue with that, is I’m the person that if I choose that type of location, will constantly be “catching” it with my thigh, and breaking and printing cradles. I feel I need a vertical plane higher than my waist. But not everyone bumps into things as much as I do.

A hook or post definitely can work with that hanging loop. The reason why I wanted a cradle instead is because I wanted to capture it in an angled position that allowed me to use it as a control even without having to pick it up. So I have the option of handheld or cradle-held. With it positioned in this cradle, it is almost in the same place and almost at the same angle as the touchscreen used to be back when I had an SKR board with a BigTreeTech touchscreen on the top.

I do have some cup hooks somewhere I’m fairly sure. Oh well, it’ll be the weekend before I can get back to it anyway.

Just a quick “thankyou” to Doug for beta testing this for us, the instructions, the mounts and for being an outstanding member.

There is a new PR branch now called “FileFixes” and it has a nice touch, so that when you run a cut job from the “FilePreview” screen, it automatically switches to the “Status” screen to display progress bar and other options for while a job is running. Nice.

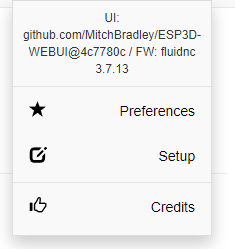

Joining the “Early Adopters” club… took only a few minutes to follow M5Dial Pendant | Wiki.js (clone FluidNC and FluidDial), open the Platform IO and click Upload Filesystem Image! The longest wait was while Platform IO downloaded the toolchain. (Initial oversight I made was clicking General->Build/Upload instead of Platform->Build Filesystem Image/Upload Filesystem Image. If you do the prior, you won’t get icons.) All the library patching etc. doesn’t seem to be required, now that it’s released.

Now off to Vetco Electronics (toy store in Redmond, WA) to get some connectors and some kinda nice cable for it…

[edit: ooh, web UI 3 test is up… initial test didn’t show machine coordinates, so back to WebUI2 it is for now…]

Cool. Keep us posted

Great work compiling this all together. Thank you. I got the M5 Dial wired up ready to go. I’ve made it to the firmware stuff. 178 pages are a lot to go through. Will you be doing any type of wrap up so far or step by step with using VS. I know this is a lot to ask while you have already done so much :). While I have some experience in VS I still need some guiding as I don’t use it very often.

Hey, is Kenworth still in Redmond? I worked there in 92, wow, I am old. ![]()

Doh, that is Renton, not Redmond, sorry!