As an option I suggest to use the two spare 5V lines (A/B Port) with series resitors (220ohm) as power source for momentary switches with standard red/green LEDs.

https://www.amazon.de/dp/B07GB54BF3?ref=ppx_yo2ov_dt_b_product_details&th=1

Thanks for the info!

Those momentary switches you linked to look pretty much exactly like what I’m using.

Re. series resistors (220ohm) — are those built into the switches or are you talking about something separate that you added? If it is separate, can you let me know the reason / benefits of them, and maybe link to them?

LEDs are just a diode, so they don’t work well to limit current. They have a certain voltage threshold you need to meet before any current will flow, but as you go above that the current climbs very fast and they burn out. An LED might have 2V as that offset (called the ‘forward voltage’, because that’s what the voltage drop is in the ‘forward’ or normal conduction direction). Anything above 2V will have current flowing, anything below will not. The thing is, for anything above 2V it looks like a short circuit, so even at 3V it will already have far too much current, let alone at 5V etc.

The way we approach this is to add a resistor to change the ‘slope’ of how the graph of current vs applied voltage. If we’re putting 5V onto the LED and the LED has a forward voltage of 2V, that leaves 3V that we need to drop and not apply to the LED. If we want 20mA (default test current for an LED) then we would use V=IR rearranged to be R=V/I. 3V divided by 20mA is 3/0.02 = 150R. Alternatively, You can rearrange that to be I = V/R to tell you what the current will be with a given resistor, so 3V/220R = 13.6mA. That’s why a 220 ohm resistor has been suggested.

The way to know if you need a resistor or not is to first check the datasheet/product description and see if it says to. If it doesn’t say anything, I would try it with a plausibly sized resistor and see how that goes in terms of brightness or by measuring the current through it with a multimeter. If the current/brightness is roughly what you expect, you needed the resistor. If the current/brightness is way too low, you can try a lower resistor or no resistor. Another alternative is if you’ve got a bench power supply that you can adjust down to 20mA current limit, you can set the power supply to 5V/20mA and run the LED off that. If it sits fine at 5V/20mA or similar and the LED looks good, you know you can use it at 5V with no resistor. If it goes into current limit and says 2.5V/20mA on the front, that definitely needs a resistor. The good thing about that method is that you can wind the current up and down to see what kind of current you want for the brightness you want.

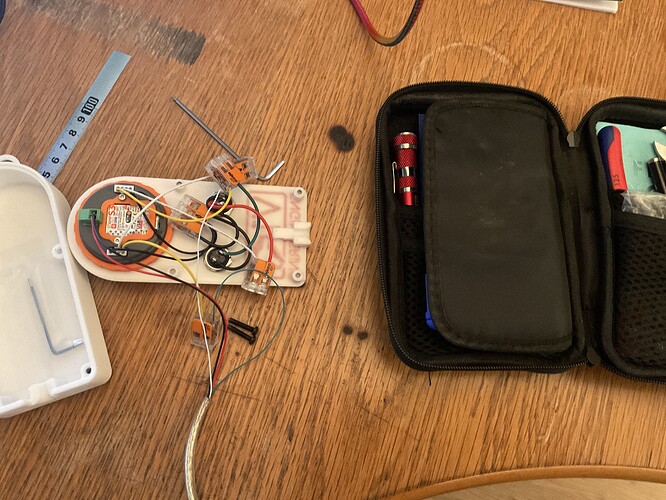

@jono035 — Thanks for the helpful explanation! Electronics is a whole world of complex and confusing things. The LED momentary switches I ordered say “3-9V(5V)” in the product description, and the link to them is below. I installed them without any resistors, and they work, and the brightness is what I had hoped for. I own two multimeters, one of which I can lay my hands on (the other is MIA). Actually using the multimeter is usually as confusing as trying to understand why I need to check something!

Two possibilities:

- You get either a switch with just a LED (my case) - you are responsible to add an series resistor

- You get a switch which is specified for a dedicated voltage (series resistor included) - your case

I just used the latest beta firmware for the Fluid Dial Pendant, which also required using a pre-release firmware for the Jackpot as well, [see above for details] and it works great as far as I can — as long as I don’t try to use my new cradle because the magnets in my cradle are apparently able to disrupt the pendant. I used the pendant to home, jog, probe, browse G-Code files, preview a G-Code file and run it, and the job (which took over an hour) ran flawlessly. The task ahead for me to experiment and create a new modification of my cradle that either reduces the number of magnets and/or repositions them or eliminates them and uses some other method of securely holding the pendant in the cradle unless the CNC operator intentionally wants to remove the pendant from the cradle.

I just used an Xacto knife to pry out the two magnets in the center of the upper row, on both the pendant case bottom and the cradle, reducing the number of magnets from 8 to 6 (4 on the bottom row and 2 on the top row, in the outer positions) on both cradle and pendant, so total is down from 16 to 12. I then ran the pendent through its paces, and it did not seem to have any disconnect issues. I will keep testing.

Mitch Bradley sent to me, “Personally I would suspect a loose connection more than magnetic interference.”

And I had to confess, I also took the pendant apart and tried to make sure the connections were good. So that may be it. For now all I have are theories. Will try to not reach a conclusion until I have more time and testing.

Mitch also added, “The tiny wires that go into PH connectors are prone to breakage. Very often the supplier uses super-cheap wire with only a few strands, and any amount of flex can cause a break, especially right where the wire enters the connector pin. Depending on how the wire is oriented, sometimes the broken ends will touch and make connection, then a little vibration will disconnect them, then they might touch again, …”

Re. the tiny wires: probably is my issue, and it probably related to having to take it apart and pry the crimped wire ends out of the connectors to rearrange them and put them back!

The latest version of Fluid Dial firmware [see above for details], combined with the right branch of the FNC firmware, seems great. Absolutely love it! I have only two observations so far: (1) the file browsing with spinning the knob, seems like the scroll direction is backwards. When the scroll bar was present, it seems like the scroll bar should be going down, with that right side of the knob going down right with it. As is, the knob has to be turned counter clockwise to get the folders/files to scroll down. (2) once a G-Code file is launched, it seems like the Status screen should appear, with the progress bar etc, instead of having to go back through all the folder structure and main screen to get to the Status screen. Other than these very, very minor things, this thing is awesome!

Well a new wrinkle in testing. While running the MSG_JSON branch of FluidNC firmware, I noticed that homing was not working right (initiated through the WebUI, homing was either failing with a warning, or moving so slow it would take 15 minutes or more to home, if ever).

I re-installed FluidNC version 3.7.12 and instantly the homing was fixed again.

Then I re-installed the MSG_JSON branch again, and the homing issue instantly returns.

Then as soon as I re-install 3.7.12, the homing works right again.

I don’t know what to make of it.

Latest on this from Mitch of the FluidNC dev team:

It has to do with an attempted fix for a problem whereby WebUI would often make you retry a connection with “is your FW correct”. The difficulty is that [ESPxxx] commands behave differently from $ commands which behave differently from GCode, in terms of when the line interpreter returns the ok or error. That in turn affects when the HTTP request is completed. It is all very complicated.

[later]

Suffice it to say that the GRBL protocol has some horrible aspects for transmission over HTTP.[later]

Well isn’t that special. I think I might have fixed the problem, but my board just stopped connecting to my wifi.

Well I am sure he has plenty of spare boards to test with. It is also good to know they might have fixed a problem that sounds pretty major.

I know Mike has made some tweaks to the [espxxx] stuff so hopefully this all comes together sooner than later.

It would be really cool if he digs in deeper to the wifi stuff. My gut says it can be even better than it is. He has not touched any of that in a long while.

I just now re-built and installed both the FluidNC firmware (for Jackpot) from the latest MSG_JSON branch and the Fluid Dial firmware from the latest ReactiveJSON branch. The file browse rotation direction now matches the scroll bar direction! Cool. The scroll bar is back, but only on the first, top-level folder. On subfolders it is not present. The homing issue is still happening. When I home from the WebUI it does not home. When I home from the dial pendant it does home. Just wanted to report back…

Today, Mitch Bradley (FluidNC dev team) pushed another update of the Fluid Dial firmware in the “ReactiveJSON” branch. I again used VSCode (and the PlatformIO extension) and built and uploaded the latest firmware to the dial pendant. I had already done so for the Jackpot, using the latest “MSG_JSON” branch for that. I posted the following test results message in the dev thread on Discord, and wanted to also share here:

OK, I have now been running the latest build (MSG_JSON on FNC and ReactiveJSON on Fluid Dial) for quite a few real world cuts. I love this dial. It’s quite usable at its current level of development. I still see most cut jobs have the dial say “N/C” during most of the job, switching to a state of “RUN” right near the end (of a 5-8 minute cut job), and after the job is over, a brief period (maybe 20 seconds) when it says “N/C” but then switches to “IDLE” and lets me adjust height and launch the next cut job. I’ve been able to do multiple cut jobs in a row without needing or touching the WebUI. Again, I really like this dial. The WebUI is great, but I think I like the UI of the Dial even better for a lot of routine uses.

I should add, that it’s possible, even likely, that I have a wiring issue — intermittent short — ever since I had to rewire it to adjust to the new schematic. So, my “N/C” status issues may be on me.

There may be (seems to be) need of additional testers. If you have wired yours according to the new wiring schematic consider installing the MSG_JSON branch of FluidNC firmware on Jackpot and ReactiveJSON branch on the dial, and take it for a spin, and report how it does.