I hate those spiral things…the “Chinese finger trap” style expandable ones are a bit better…but always start to fray on me way too much and heat shrink can only hide so many sins. And when you need to branch off they don’t help much at all.

I really like the self wrapping fabric style of sleeving that Prusa uses (or at least used when I got my MK3s) I finally found some on Amazon but it was too rich for my blood. Still, may pick some up in teh future to go over the lacing if I find I don’t keep messing with things on the LR4.

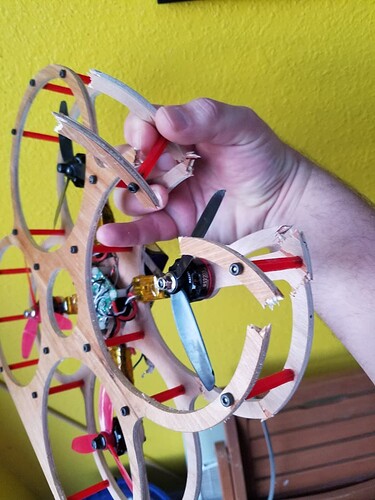

Thanks! That was a fun build. I had hoped to use it to explore an abandoned date farm near me - but the ply was both heavy and weak making for very poor performance and major damage in even mild crashes.

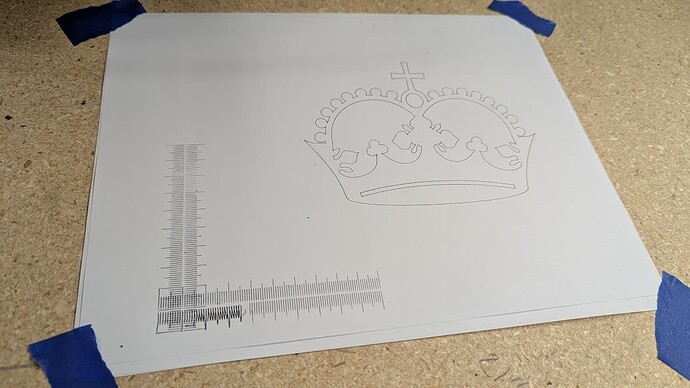

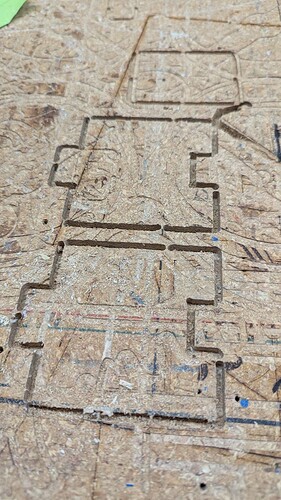

Between crashes and issues with my oversized MPCNC I went through a lot of frames with minimal actual flying:

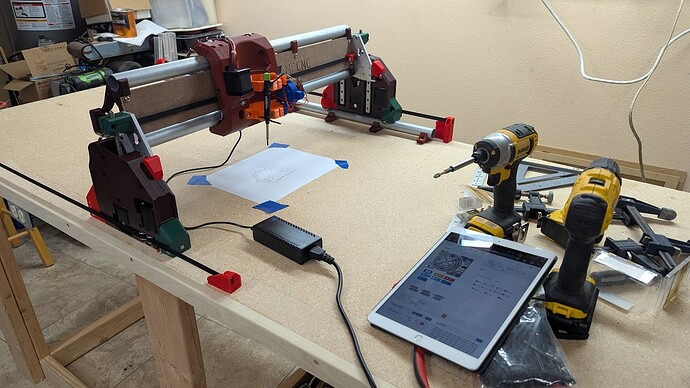

I actually just threw out a big stack of circles from the top cuts…my girlfriend who’s been pushing me hard to throw more stuff out actually liked them enough she wanted to keep them…but relented and accepted she probably wouldn’t do anything with them either. And if she did want some I could just make her new ones.

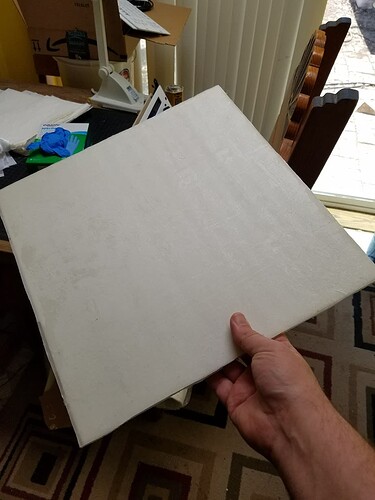

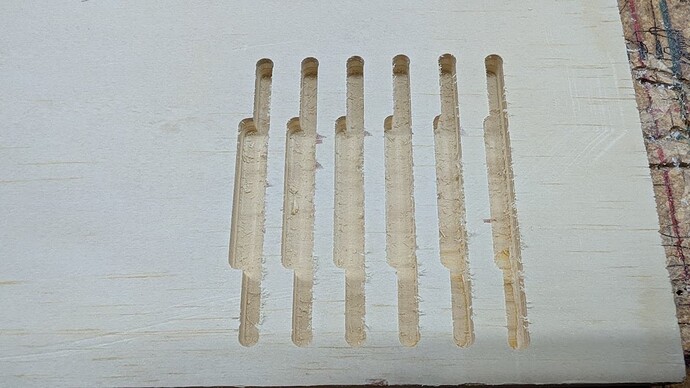

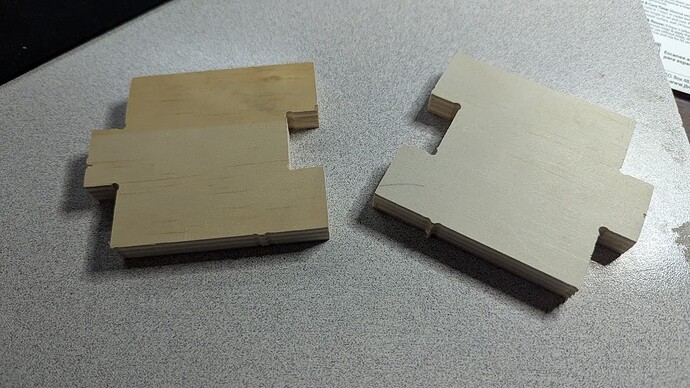

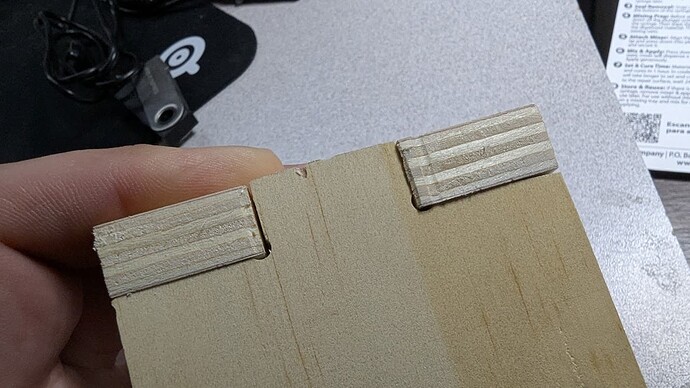

I did a bunch of tests to try and find another material that would work. I know it’s workable with CF plate - but the cost for that is crazy high and I couldn’t bring myself to waste that much expensive CF. I tried sheets of PVC but they were too flimsy - so I tried one sheet of polycarbonate and one of PVC:

But that made it worse because now it was both fragile AND flimsy - the PC wasn’t stiff enough so the frame had major vibration issues and when it crashed it still broke. The PVC help up fine…but it was just too soft and flexible.

I played with chemically welding some pieces to it to stiffen it but that didn’t work well either.

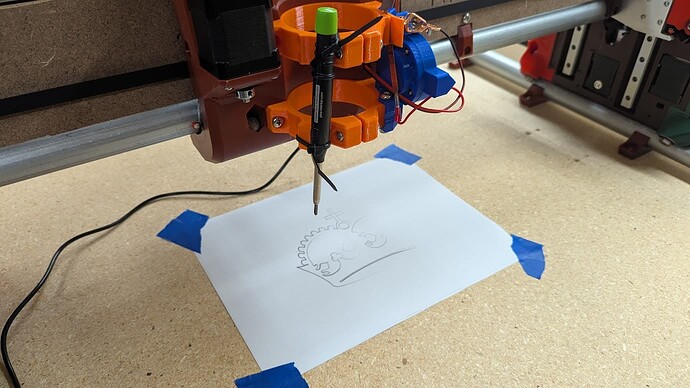

So I started experimenting with different laminates. I knew I could use fiberglass on the light ply but even the bare ply was heavier than I wanted. I started doing experiments with light glass over foam board:

But…the light glass was more expensive than I wanted and it started getting heavy again.

I had started to do more testing to find a DIY composite material that was cheap and light - peeling the paper off foambaord and using paper sold for protecting floors during construction seemed to have potential. And I was about to start cutting up old jeans to laminate into panels to try ( I thought a jeans copter would be pretty cool even if it wasn’t practical) but that all got set aside when my wife suddenly passed away. I actually just threw out a lot of the test pieces I had made as I cleaned out the old shop.

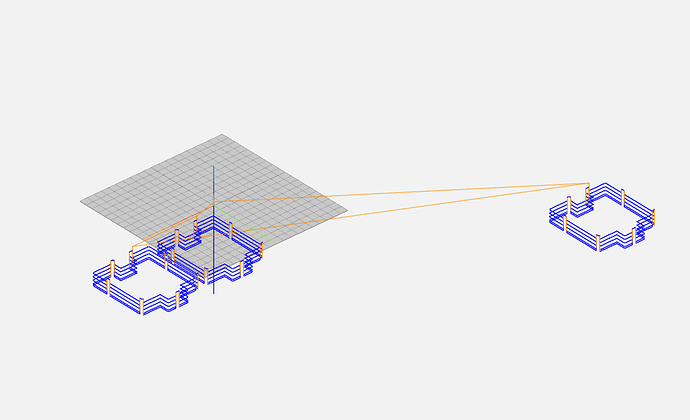

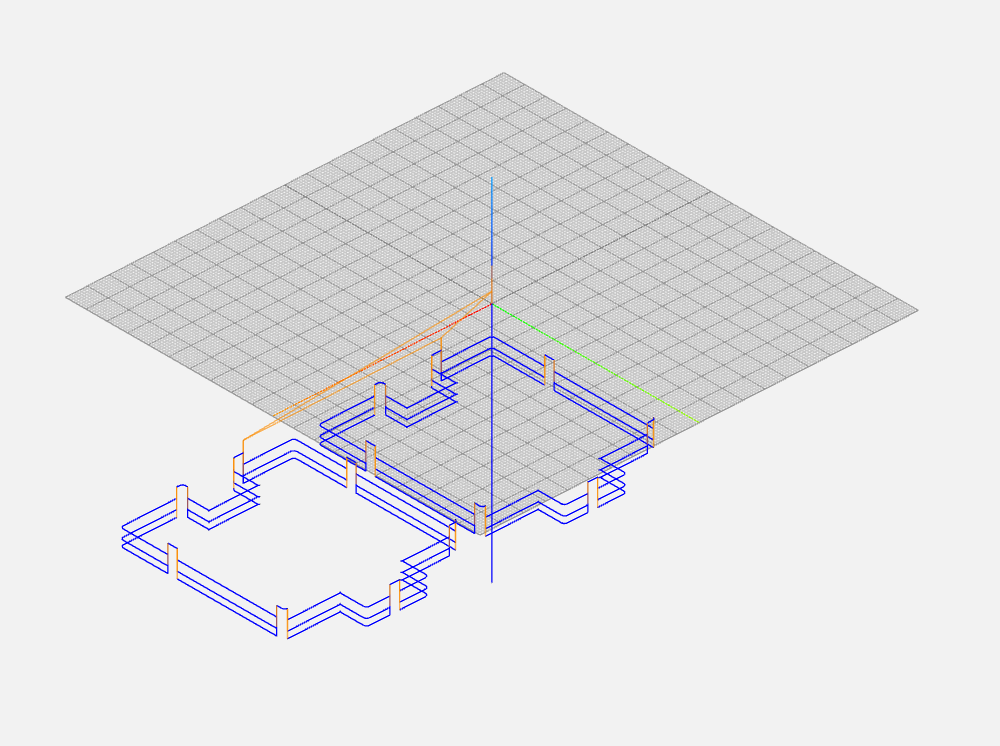

Maybe once the LR4 is up and going (getting really close!) I’ll dust some of those ideas off and start experimenting to find a light and cheap DIY composite again…