Well, I think I am being forced to conclude that this is a failure.

I think there are still some good concepts, but specifically, going for 100% printed (in PLA to start with) and using the printer heat bed as heat source is not good. Either the bed is anemic or the heat transfer to the air is extremely poor, and the hot air source is not nearly high enough. Then on top of that, a huge amount of heat is being lost before it can do anything useful.

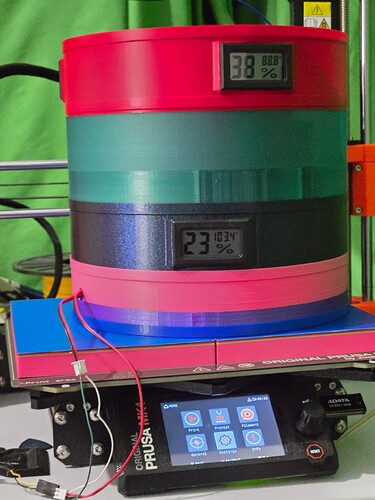

I let the system run for a couple hours today, and apart from a slightly lower ambient humidity, the result is essentially the same as the last picture.

The inlet is about 47% RH at 72F.

After passing the heat module it’s 18% RH at 103F.

Then after the silica gel it’s 32% RH at 88F.

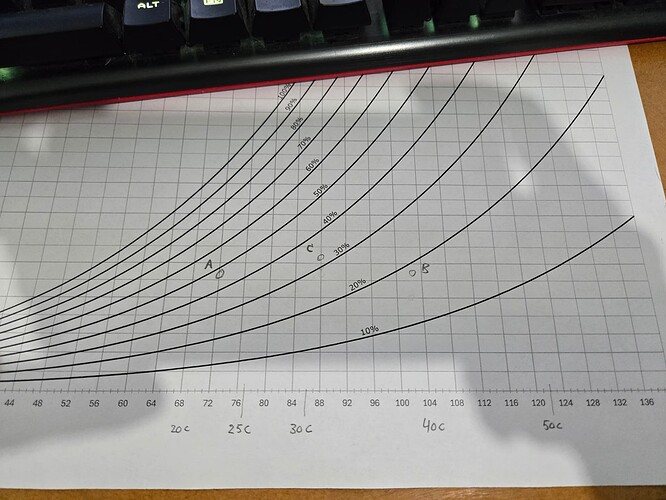

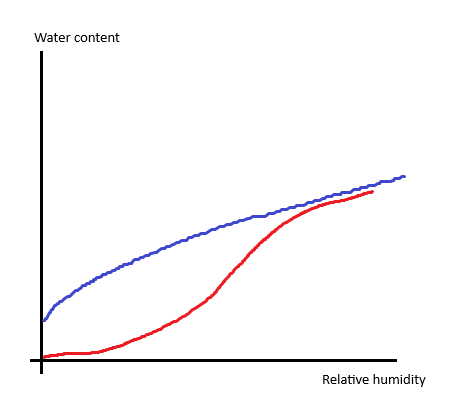

The inlet is at A. After heating it’s at B and since it is being purely heated it should (and does) move horizontally. The vertical axis is absolute water content, which doesn’t change from A to B even though relative humidity does change.

From B to C the temperature decreases and the absolute humidity does increase slightly, meaning it is drying the silica gel a bit, or maybe it’s doing nothing and it’s within the margin of error of the sensors.

But either way, I feel like it is not nearly hot enough to be effective. Even when I remove the silica gel and run an empty plastic chamber, the temperature is barely any higher, so it seems the heat loss is really bad.

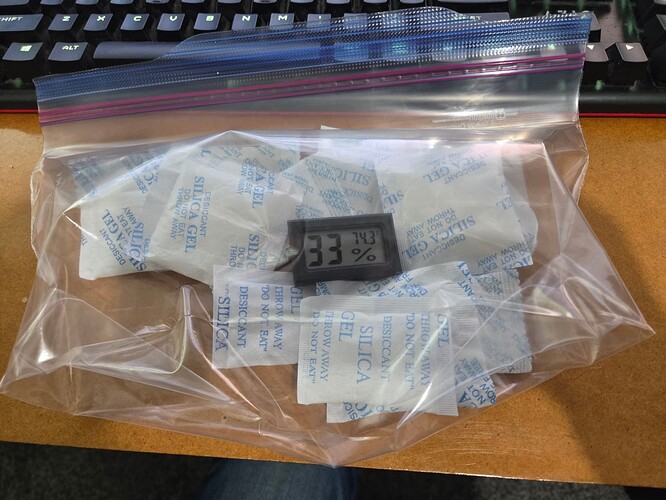

It doesn’t do nothing, and this old silica gel is now at 33% RH instead of 40 something, but I’m still saying it’s a failure.

On my previous iteration I cranked the heat bed temp up to 65 and it started to melt the PLA, so I kept the bed at 50C this time.

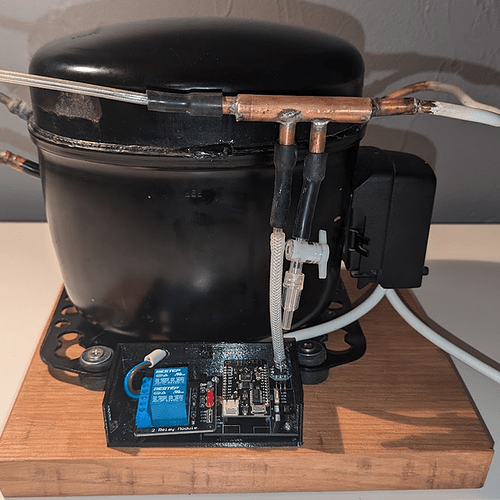

I think a dedicated heater is the way to go, and it needs a controller, and it can’t be made from PLA, which should have been obvious from the start.

I’ll have to rethink the consequences for the requirements. If the system is standalone with sensors and a controller, then maybe it can be fully automatic for continuous use with not much more investment. (Continuous use would mean redirecting airflow and cycling itself to regenerate the desiccant.)