Inspired in part by

New MK4 is out! - #612 by bitingmidge and

Building a filament dry cupboard?

And this video of Adam Savage’s cabinet https://www.youtube.com/watch?v=taeS72yO__k

And CNC kitchen experiments https://www.youtube.com/watch?v=6tHInlFfMcM

Here are some thoughts:

- Desiccant doesn’t really “dry” as much as it keeps the humidity stable

- I don’t like Adam Savage’s solution because that dehumidifier seems like the wrong tool for the job and will waste power

- A room dehumidifer tries to get a high volume of air to be not too wet

- The task requires a small volume of air to be as dry as possible

- A small hose could pump a small amount of very dry air into a box

- Multiple boxes could be connected in series

Requirements are:

- Must produce a small volume of extremely dry air

- Must be as low cost as possible, <$50 preferred, <$100 mandatory

- Must consume as little power as possible (extension of #2, TCO)

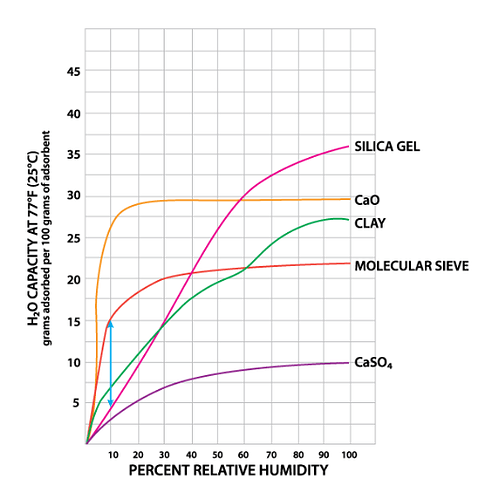

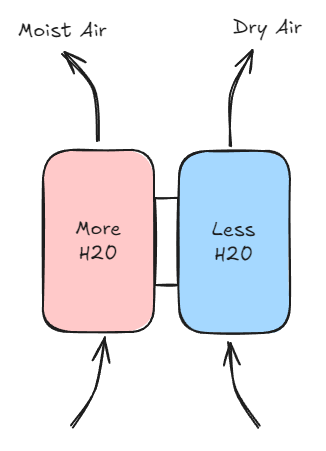

Here is a concept. Suppose you have a TEC and you have two chambers with silica gel, and the TEC establishes a mild temperature differential. (The hot side does not need to be extremely hot, nor does the cold side need to be extremely cold.)

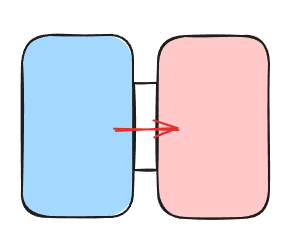

Now suppose you have a closed cycle air pump that circulates air between the two sides while the temperature is maintained.

Because of the temperature differential, the cool side will accumulate more water, and the warm side will accumulate less water. Note that the warm side will release water to the cool side even if the warm side is still below the normal regeneration temperature that releases water to ambient air. It should be the same mechanism by which a warm, wet surface in a closed system will cause condensation on a cooler surface, regardless of whether the temperature is near boiling. Only the temperature differential is necessary.

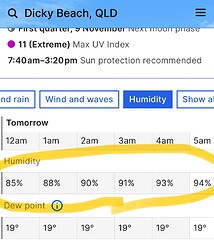

Now after a while, suppose the temperature were reversed and each were vented to the atmosphere. The side with more water (left side), now warm, will reject moisture to the ambient, and the side with less water (right side), now cool, will absorb moisture from the ambient.

In this system the moist air and dry air depends on the temperature differential, where a high temperature differential is effectively regenerating the silica gel the old fashioned way by getting it hot. But the point is that even with a mild temperature differential, the system will produce a mild drying effect.

The downside is that the drying effect is rather weak, but the advantage is that nothing gets very hot, and the heating/cooling is energy efficient.

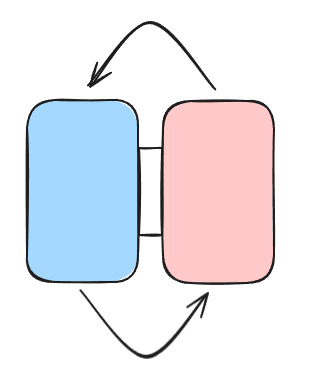

So the next step is to stage these like a bucket brigade.

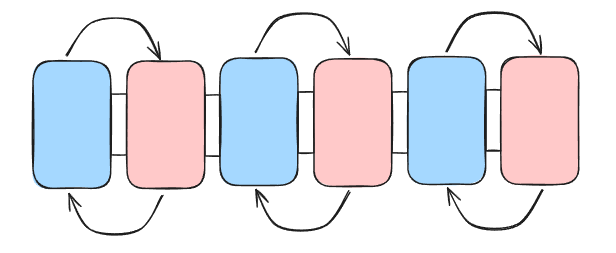

During the “A” cycle, there are three closed loops and alternating warm/cool chambers:

The heated chambers will transfer their moisture to the chamber to the left.

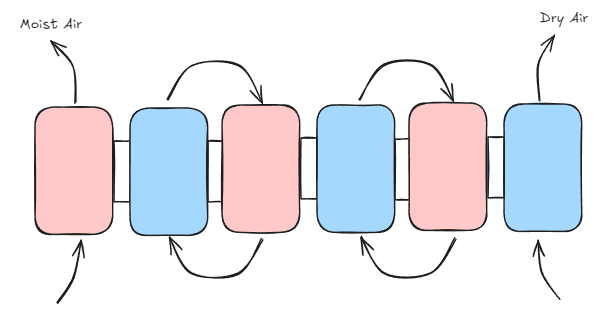

Then, after a while, the cycle changes to the “B” cycle, with two closed loops and two open loops:

Each individual stage with a modest temperature difference can only achieve a modest humidity difference, but when they are stacked in series like this, I think each cool chamber of desiccant can pull the humidity of the next warm chamber even lower, so that the dry chamber on the far right can be extremely dry, even with a modest temperature difference.

The TECs are cheap and with some 3D printed ducts and stuff, maybe this whole thing can be built for between $20 and $50.

Thoughts?