25degC 75% RH air = 17mg/L, 20% RH = 4.6mg/L. So assuming every time you open it you fully exchange the air (which is probably somewhat pessimistic), you’re adding ~12mg/L or 1.2g into a 100L tub. If you have 100g of silica gel in there, that’s a ~1% increase in water. At 25 degC and 20% RH Silica Gel is about 10% water by weight. At 25 degC and 30% RH it’s at 15%. So In theory each time you open that tub you’d be adding enough water to increase the RH by ~2-3%.

No I think it’s realistic - open container - take out filament, faff around a bit, close container… 25° and 51% humidity is realistically the best we’ll ever see and that’s on the dozen or so days we run the air con. Maybe running the AC is just another cost of making small useless prints! ![]()

I currently have a sketch container that will allow up to 500gms (per 10 litre box) - I’m committed to 200 - ideally I’d like to limit recharge to twice a year. Coming home after five months away to 59% in all of my boxes was a bit sobering. That was a product of me having a zillion dicky little containers, never fully recharging them (four hours @40% with filament in the food dehydrator, and never successful in the Eibos, and then giving up!

There are lessons being learned in this thread - none of them new, none of them terribly important for the majority of PLA printing people, but I’ll soldier on, as long as you can keep backing me up with actual science!

I’m presuming that you’d try to minimize the amount of time with the box open and it won’t be instant. It’s a worst case asymptote, at least, but it doesn’t seem that bad to me so I think it’s more likely to be dominated by air exchange/leakage.

I was discussing this and explaining partial pressures of vapors to a colleague and I realised I had never really put 2 and 2 together to consider humidity as having a partial pressure. I had just kinda assumed that if there wasn’t any real air movement there wouldn’t be humidity transfer whereas in reality you need to consider all the components of a gas separately. Because of that, you’ve gotta consider the airflow paths as if they’re being actively pressurized. It’s closer to trying to seal a container against a positive pressure because as far as the water vapor is concerned, there’s a significant positive pressure in the wetter air that will force transfer to the drier air.

Thinking about keeping the RH down, we have an always-on dehumidifier in my fiance’s library/crafts room and it has been running periodically all day because it’s raining and pretty humid, about 80% in the entryway downstairs. The library room is at 60%, the door is partially open and the dehumidifier has been using ~300W when it’s running with about a 30% duty cycle so far today for the past 6 hours totalling about 150Wh… Good way to knock the worst off it, anyway. I might need to do the same with my office as I don’t spend as much time in there at the moment and I noticed some mold around the window frame and on my keyboard ![]()

![]() This has been working just fine for me, even in Florida with the stupid humidity. Was a whopping $40 on amazon. Then I store and print from a big ziplock tub with rechargeable desiccant containers in it.

This has been working just fine for me, even in Florida with the stupid humidity. Was a whopping $40 on amazon. Then I store and print from a big ziplock tub with rechargeable desiccant containers in it.

Yep - see my post above - Filament Dehumidifier - #55 by bitingmidge

This whole thread is about me chasing my tail!

Out of curiousity (I live in a similar climate) how often do you run your AC? My observation is that many (most?) in the US consider “climate control” a normal fact of life.

In Aus this is not generally the case - ours is rarely used except when the temp hits around 30 (c) indoors, when it’s really chilly (say 16° - Brrrrr) or like now after a few days of rain outside when everything inside just feels soggy! Living by the ocean with a thin invisible salt film on everything doesn’t help either! ![]()

It’s on my list! ![]()

about 350 days a year here in the panhandle of FL. We get about 2 weeks a year where we don’t have to run it. Today was one of those nice days LOL. But yes, I don’t see how yall do it. Ours is always on (not running non stop 24/7 but cycles when it needs)

It’s just what one is used to I guess (and one is used to not paying terribly high electricity bills! ![]()

![]() )

)

If filament is kept in AC space, then it doesn’t count as a hot humid environment! (I guess yours is in your shed!)

AC doesnt drop the humidity that much. I am in an old house (1967) with a walkout basement (very rare for FL). It is not sealed the best AT ALL. In my basement room where my 3d printers and Filament are there is a Mini Split AC in here, as well as a large dehumidifier that is on 24/7 (has condensate pump to keep it drained) and the humidity is still 37%

I start noticing print issues any time the filament gets above 20-25%. So because of that I keep everything in dry boxes that I print from and also some larger ones that I use as dry storage. The PET-CF goes in the dryer for minimum 6 hrs but usually 12-18 hrs then straight from there to the dry box to start printing. I have one printer that is all it does it print the PET-CF so I usually keep it moving when I am home.

Just for fun, I made a canister to hold 200 grams. It’s the one in the photo about five or seven posts up.

It’s stupidly complicated but really nice none the less - spoiler - you really don’t want to use those cardboard spool centres, so I’ve made a plastic replacement that works a lot better.

Told you so! ![]()

When we were still in FL, pretty much any time the temp was over 75f the ac was running. Unless it was one of those weird days that the humidity was under 70%.

It does if your house isn’t a sieve.

AC drain line got clogged by a dead lizard. ![]() Trash can lid was the quick solution, only had one bucket, and it wouldn’t fit through the air return filter door anyway.

Trash can lid was the quick solution, only had one bucket, and it wouldn’t fit through the air return filter door anyway.

Yeah, we have the AC running at the office pretty much constantly and it’s 10% lower RH than outside even though we have a fresh-air intake fan that’s always running as well.

In our lab at our last office there was no good air circulation and we had an extra mini-split heat pump in there in case we were testing something that added a bit more heat load to that room. We ended up never using it because it would instantly drop the RH enough that we started getting massive static shocks off damn near everything. One of the guys I worked with was particularly susceptible to it and every now and again he’d go to walk out of the lab and you’d just hear the quiet clack of him getting a shock and then swearing. Not an ideal situation for an electronics lab.

And people wonder why I get confused.

Three days on, and the 200 gram container is presently reading 11%, the kilogram one stabilised very quickly and remained at 17% Ambient this morning 77% @ 26°C

Note @barry99705 -That’s around 79°F, which is the temperature we run the AC at when we do! ![]()

Why is the Kg (otherwise empty) container full of blue Silica beads? Mine discolor from an off white as they absorb mosture, going yellow or orange.

Why is the 200G one full of white beads?

Am I seeing that wrong?

Just trying to get some sort of base - while I have a couple of spare containers waiting for delivery! The blue ones go pink. There’s more than a kg there just to see if it makes a difference.

The orange container has 200 grams of blue beads - what you are seeing that’s white is my empty collection of 60gram canisters - they have a central core and are a pain to refill - but like all good hoarders, I’m not ready to say goodbye just yet! ![]()

When I was going to college in Fairbanks one of our computer labs had a row of benches around the room with bar stool height chairs, think those plastic school chairs, but taller. These didn’t have the metal rivet to the frames, so in the winter you’d build up quite the static charge. Buddy of mine reached up to his laptop and shot a one inch lightning bolt to it. Laptop just shut off. ![]() Luckily it powered back on.

Luckily it powered back on.

It’s so far opposite here that it’s unbelievable - in lots of older houses (say 40 years plus, the build up of salt from the air oxidises on the contacts on the inside of power sockets, and eventually the continuous cycle of damp builds up to a drip - I wish I had photos of the green tears rolling from the sockets down walls!

It’s a genuine thing! ![]()

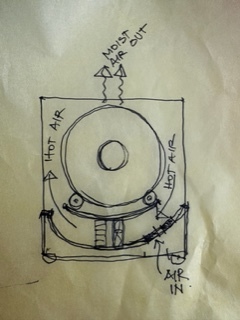

Here’s a sketch I did a year or so ago in conversation with the guys at Eibos.

Here’s the current SOVOL model - I can’t see how the fresh air gets in or how the moist air gets out, but the circulation seems to work a lot better (clip starts at that part) 1:16 in.

@jono035 how would you solve that ventilation problem (in theory) - I think the open source dryer model is starting to look like a clone of a bit of cheap chinese stuff! ![]()