That definitely wasn’t the intention. I’m always happy to expand upon any thoughts that didn’t come across clearly.

I disagree. With food you’re trying to rapidly get from very, very wet to dry enough to be safe quite quickly. With filament you’re trying to go from extremely dry to extremely, extremely dry. Consider something like apple slices. You’re starting from ~80-90% water content and trying to relatively rapidly bring it down to ~10-20% water content. It might still take a long time to get all the way there but the goal is to at least start the process quite rapidly so the surface dries out and becomes inhospitable for bacteria/mold. For filament you’re starting at maybe 1% water content (10g in 1kg of filament) and trying to bring it down to as close to 0 % as possible without being as bothered about speed because fundamentally you can’t really slice up the filament and the surface area exposed to direct airflow is much lower.

Obviously you’re loading different amounts of material into the dehydrator (several kg of filament vs maybe half a kg of fruit tops but the total water quantity is still way, way less and the dehydration time is way way slower.

Those two situations are different enough that I don’t think I’d put much stock in what the standard dehydrator design is intending.

I’m not sure what you mean here?

This is just my musing on the subject to make sure I’ve got it straight in my own head as much as anything, so apologies if it it’s stuff that’s already known or obvious to you.

Depending on the oven, the ‘fan forced’ nature is really just stirring the air within the oven, not necessarily venting and adding more air in. That’s the big difference between a conventional convection oven and an air fryer. The conventional oven is mostly stirring the air within the oven to make sure it’s evenly distributed and that there are no cold pockets of air or ‘shadowed’ sections of food that aren’t heated by the radiant heating from the walls while an air fryer is mostly bringing in fresh air, heating it and then exhausting the hot, wet air. The latter is why they are so much better and making foods crispy.

So when the oven heats up, it’s not actually removing any moisture from the air, it’s just changing how much moisture the air can hold (hence the Relative part of Relative Humidity, RH). So say we start with a 40L space within the oven and it’s at 27 °C and 70% relative humidity as you say. That’s 18g of water per cubic meter of air so 18mg/L or 72mg of water. It’s 72% RH because fully saturated air at 27°C can hold 25.6mg/L. If we turn the oven on and ignore any air exchange/venting, once it gets up to 100°C then we’ve still got the same quantity of water in the air in the oven, 72mg. The difference is that the hot air can hold a LOT more water before becoming fully saturated, 584.5mg/L at 100°C or around 20x more. That means the relative humidity (how much water is in the air vs how much water the air can hold) is now around 3%. The heat hasn’t made it any less wet in absolute terms, there’s still the same mass of water within the oven’s volume, it has just meant that more can be absorbed so it it’s drier, relatively speaking, and that water will far more readily evaporate.

So the next thing is to consider venting within the oven. If we say that every minute the oven ejects 1L of hot air and brings in 1L of cold air then we can figure out what that does the water content within the oven’s volume. Ignore the change in volume of the air as it’s heated for the moment. That 1L of cold wet air (27°C/70% RH again) that comes in will contain 17mg of water. The 1L of hot dry air (100°C/3% RH) that goes out will also contain 17mg of water. The total volume of water in the oven doesn’t ever actually change. We could run it like that for a few hours, by which point the air has been exchanged fully several times over, turn off the venting and then cool it back down to 27°C at which point it would go back to having 70% RH because the total volume of water never actually changed at any point.

In reality this gets complicated slightly by the density of the air changing with temperature as well, but that’s somewhat negligible (1.2 kg/m³ vs 0.93 kg/m³) and not obvious how it affects things (would cause some air to be pushed out of the oven while heating and then some to be sucked back in while cooling, etc. so I’d guess that it’d even that effect out even further).

So the next step would be considering what happens when we add stuff to the oven. If we ignore the venting part and put a tray of water in the oven then the water will start to evaporate (or boil at a hot enough temperature) until the relative humidity hits ~100%. At that point the 40L of oven volume has around 20g of water in it. Let’s ignore boiling, actually, as that makes things way more complicated. Say we stay just below boiling then that all holds true. If we just turn off the oven now and let it cool down without venting, that space will go to 27°C and still have 20g of water within it. The air will only hold 1g of water before being completely saturated so the remaining 19g of water will condense out wherever it touches a cold enough surface and you’ll have quite the soggy oven. If instead we let everything get up to temperature and 100% RH within the oven and then start venting it at 1L/min then we’ll see 1L of 100°C/100%RH air come out with ~580mg of water in it every minute to be replaced by 1L of 27°C/70%RH air that has only 17mg of water in it. So whatever is in the oven will be losing ~560mg of water every minute in this somewhat contrived scenario.

In reality there are limits to how fast the water will evaporate so it’s not likely to be coming out at 100% RH because water doesn’t instantly evaporate even in 0% RH conditions and we’re ignoring boiling here. So depending on the rate that the water evaporates, the air coming out of the oven will be somewhere between 100°C/a little higher than 3% RH if it’s a lot of air exchange and slow evaporation or 100°C/100%RH if it’s slow air exchange and fast evaporation.

The evaporation rate is also dependent on the RH so at 3% RH the evaporation rate will be MUCH faster than at 80% RH, so 100% RH basically never gets reached. For example, a 1m² pool with 1km/h of air over it at 27C/70%RH will evaporate 204g/hr. That same 27°C air at 20% RH will evaporate 540g/hr. Heating that 27°C/70%RH air to 40°C with the same water content would make it 35%RH. At 40°C/35%RH the evaporation would be 924g/hr. Similarly going from 1km/h to 10km/h at the same 27°C/70%RH takes the evaporation from 204g/hr to 500g/hr, etc. So lower RH/higher airflow both lead to a higher rate of evaporation even keeping all other things the same.

So the main way we can slow down or speed up evaporation within the oven is surface area and moving air around. Having a shallow tray of water with air blowing over it would be fast evaporation while having still air and a tall column of water without much exposed surface area would be slow evaporation.

So the parallel with all of this is how the evaporation occurs. We could just seal the filament in and heat it up which would drive moisture out into the air due to the air being relatively more dry than it was but when we cooled it down it would condense and things would get wet. As long as you’re condensing it away from the filament then you’ve basically just made something that works the same way that a heat pump dehumidifier does or how some industrial process control dryers work. This has the advantage that you’re only ever heating the air in the volume once and then you could insulate the hell out of the enclosure to prevent heat loss and it’d just sit there. The disadvantage is needing to deal with the cooling in a specific way to avoid the water condensing on/around the filament.

Alternatively, we can just continually blow tons of hot air over the filament, that way the filament is always exposed to hot, dry air and any moisture coming out of the filament will be immediately dispersed into the atmosphere. This is super simple but would be pretty wasteful to have a huge stream of hot air constantly being blown over the filament.

The mid-way point is to put the filament in some kind of enclosure and heat the air around it, balancing how much air we vent out to make sure we’re not wasting tons of energy heating air but not letting the air get too humid which will slow down the evaporation rate. Ideally we would also stir the air within the enclosure such that there’s a lot of airflow around everything to keep it evenly dry.

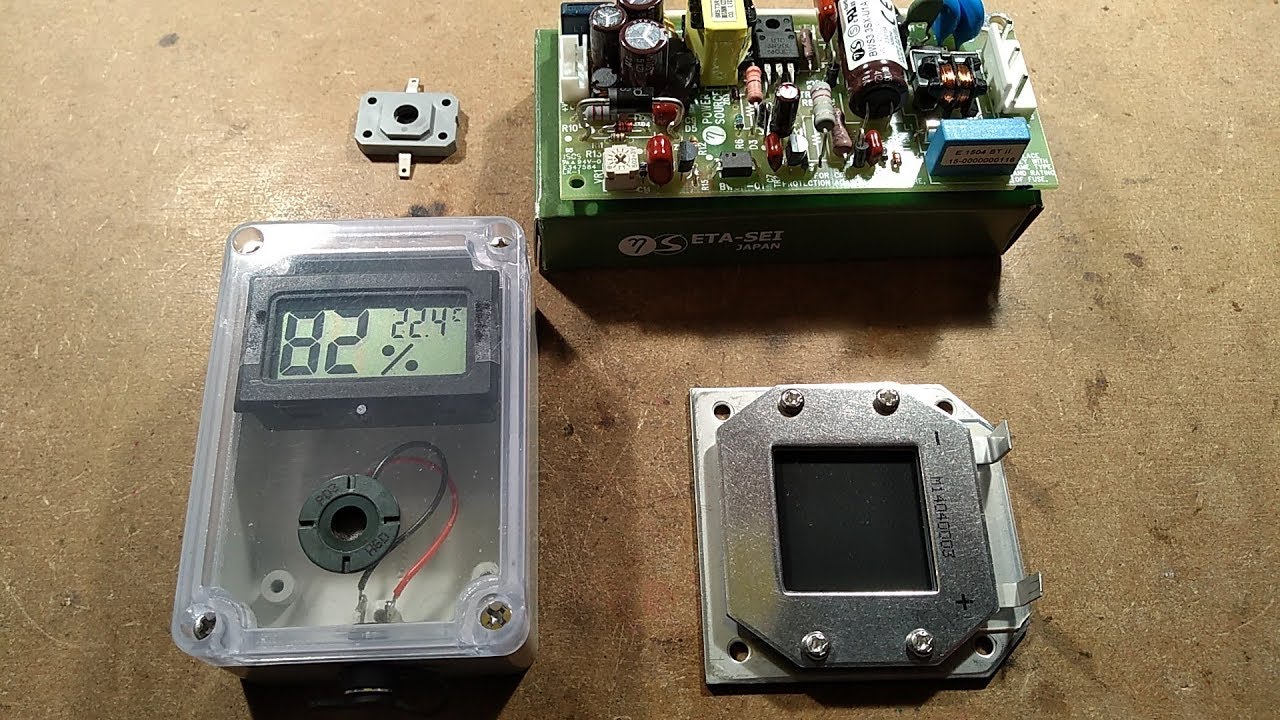

So the most hardcore option would be a system that has high internal airflow and an internal temperature as high as possible which will make the evaporation as fast as possible. The temperature control would be precise so we can get as high of an internal temperature as possible without damaging anything. The enclosure would be insulated to avoid wasting heat into the atmosphere. Venting would be separately controllable and relative to the internal humidity measurement to avoid wasting heat into the exhaust stream. For extra bonus points it would have an air-air heat exchanger so that the hot exhaust air would pre-heat the cold intake air. A lot of the evaporated moisture would condense in the heat exchanger and could be drained off rather than put into the air.

The cheap filament driers get ‘some’ of those things right. Mostly they just house the filament and blow hot air into the housing. There’s nothing internally to stir the air so there’s no good way to control the rate of venting separately to the temperature/internal airflow. The only heat the intake air so there’s no way to realistically heat the enclosure without venting, etc. They also don’t seem to do any fan speed control so the venting is always the same volume, the temperature then just depends on how much power goes into the heating element which is the only actual form of control.

Similarly, your food dehydrator will just be running the fans constantly and then it’ll have a simmerstat or thermostat that controls how hot the air coming out is by running the element more or less. Once the element is on full bore then you can’t increase the temperature any further because the power is at max and the airflow isn’t controllable. If you decrease the airflow through the stack then the temperature will rise (same power, less airflow). There will be a little less stirring air, but given the relatively slow nature of the drying process, I think the performance gained from higher temperatures will massively outweigh the slight drop in airflow.