A LONG POST COMPARING THE $200 (AUS) EIBOS CYCLOPES FILAMENT DRYER WITH A $45 FOOD DEHYDRATOR.

I’m posting this long and sometimes sad story so that others don’t have to repeat my mistakes!

1) THE EIBOS

Let’s start off by saying I’ve had some very pleasant correspondence with them after they discovered a few of my mods on Printables, and approached me. I understand they made some attempt to address some of these things with their latest and greatest model, but I do feel entirely cheated and this is still being sold in its current configuration!

I am at war with even some of the YouTube tech guys you may appreciate for their apparent thoroughness. It’s pretty clear that being able to dry a wet sponge in their tests does not make a great filament dryer, but at the time, this one had a few things that the others didn’t so I bought it and gave my perfectly good dehydrator (thirty years old and bought second hand) to my Grandson.

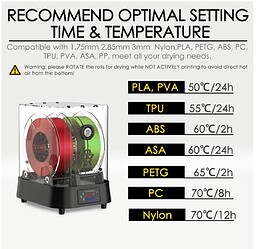

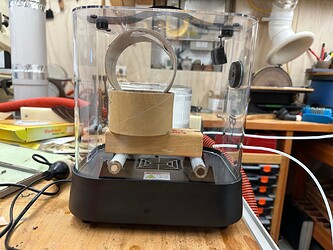

All the tests and the advertisements indicated and still do, that the chamber could be heated to 70° It can appear that way if there’s nothing in it, but what is happening is the hot air is funnelling straight up the centre and out, and not circulating around the outside of the filament. Actual measurements below.

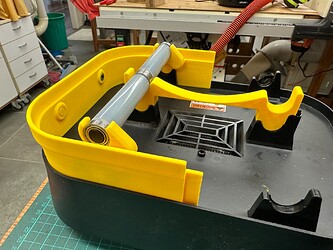

In use it was “awkward” to be kind, as it doesn’t come with a handle on the lid, and the filament feeds out of the lid so one has to juggle the lid with the filament on the base, feed it out the short run of Bowden tube, then try to do it a second time without knocking the first spool over.

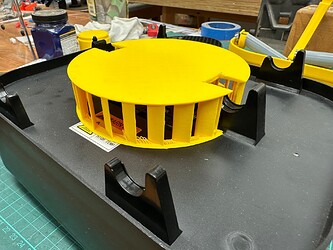

The worst defect, is that the element can deliver extremely hot air, but the filament is positioned just 12mm above the outlet. In use, this means that filament quickly overheats, the thermostat is very close to the outlet, which means that the chamber itself doesn’t get up to speed.

MEASUREMENTS -

With a few bits of rubbish to disrupt the airflow to simulate on spool, after forty minutes at an indicated 70°, the top of the chamber was indicating 51°, barely two degrees more than the food dehydrator. I have no doubt that this would continue to build over time, but that really is where the problem lies. Curiously the Eibos humidity gauge started to read the same as the other, and probably because of the seriously hot air at the bottom of the chamber, we’ve gained a few percentage points in the dehumidifying stakes over the dehydrator.

However some other measurements (with my el-cheapo laser thermometer) are illuminating

- Top side of the grill above the heater (below to where filament sits) 87°

- The surface of the centre bearing -71°

- Surface of the thermostat - 61°

- Bottom surface of the timber batten spanning the axles -68° ; given that timber is an insulator it seems fair to think if this were plastic it would be closer to the 87 if the grill directly (12mm) below it.

IS ANY OF THIS FIXABLE?

Leaving aside the question as to whether one should be in the position of doing so, I think I can make it usable at least.

Handle

I made a pretty new handle immediately and that is what attracted the attention of the company.

Keep the filament Moving

After others had reported the melted filament (and in some cases melted spools and melted vent grille) a warning was issued to keep the filament moving when not printing.

Someone on Printables developed a small electric drive, I made my "kinetic" gears to link the axles, and later simply made a key to link the two axles, so that when the active spool moved, so did the other.

The problem with these solutions is that you still have to keep the rotisserie moving when not printing, but in use my PLA filament clips softened, the filament unravelled (even while turning in the “counter” direction to the wind, and things just got generally discouraging.

Move the filament away from the heat source -

There are a few solutions about which incorporate spacers to lift the filament a few inches to keep it away from the most direct heat source - some direct the bowden tube through them to give a much more satisfactory loading situation. IMHO just lifting the spools doesn’t do anything for the fundamental design floor which gives a 30° temperature difference in the chamber, and it does provide a considerably larger volume to heat.

The food dehydrator seems to maintain a similar temperature through its entire volume.

Shield the filament from the heat source

There are also a few solutions which involve a plate or baffle between the outlet grille and the bottom of the spools, but again, given the really tight distance I can’t see any benefit in terms of air distribution.

EXHAUST AIR

There must be a reason why the dehydrator exhaust totals 600 mm2 (6@4mmx25mm approx). The Eibos has seven 5mm diameter holes at or 140mm2 - one additional 25mm diameter hole would even up the score!

I have no idea what the optimum is, but watching people modify the original eSun dryer (Rick Impy) it would appear to be at least as much as the dehydrator, although that also might contribute to the slightly lower chamber temperature?

MY SOLUTION!

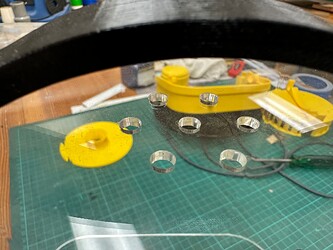

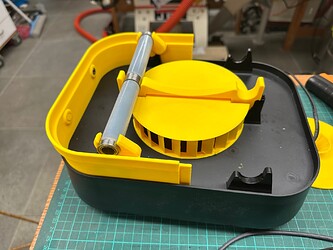

It’s at the prototype stage only, but here we go -

Yes I am going to lift everything, but by 35mm which I think is the minimum I need to reroute the Bowden tube, even at that I’ll have to bring it under the spool and it might be a bit shonky.

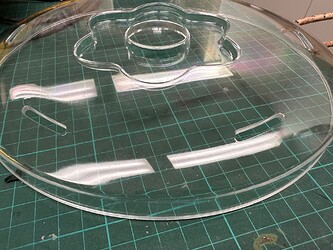

That 35mm though, will give me the ability to make a plate and a diffuser, modelled more or less on the one in the dehydrator to send the hot air out to the perimeter of the box rather than just straight up.

I’ll print it in PC I think, which might be marginal - but I’ll give it a coat of heat paint inside because I can.

I think it will all look a bit “factory” but it would be better if it works! All I have to do once the filament arrives, is print it and drill some bigger holes in the lid.

It woudl be good if I could work out how to smoke test the before and after, because I’d like to be able to say that’s one job closer to starting the LR4!

I did tear down both gadgets, if anyone wants pics I’ll upload them, but surely that’s enough for now!