I had it faster than this current speed so I might still have to turn it up a bit more ;feed rate ![]() !

!

PXL_20230430_193610026|281x500

Is your far Y axis stepper working?

I am not clear what happened there.

The Y belts look very very loose in those last two photos you posted. You’re not running loose like that right?

Also, your rail does not seem to be fastened.

The issue with multiple rail support is that the ones I printed run into the wheels at the top. I placed one on each end

I’m going to figure that issue out

No it snapped

They are but sometimes the y side with wheels stops not certain why and the other side keeps running

Then you have either printed the wrong ones or something is very wrong with your other parts. ![]()

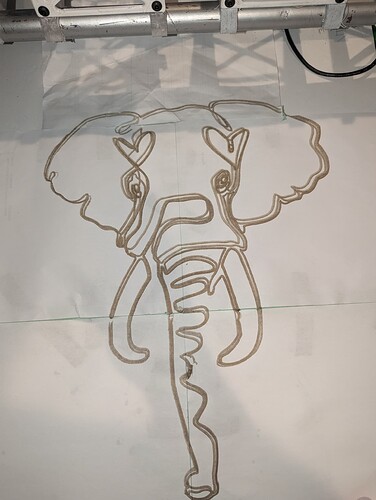

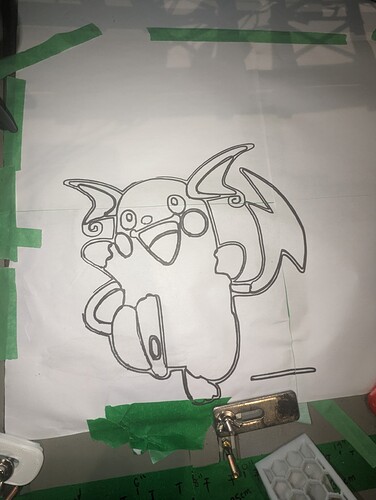

Have you tried ziptieing a pen to it and have it just draw the crown using Ryan’s code?

https://docs.v1e.com/img/old/2015/09/Test-Crown-12mms.gcode

Put that code on your SD card. Ziptie a pen to the core. Tape down a piece of paper or just let it draw straight on your spoil board. Set your z height right at the level of the paper/board and then hit print on that Gcode and if your machine is all wired correctly it should draw a crown. Get this running first before trying to get into cutting. This will help us figure out what’s going on.

I know it can be very frustrating having issues. Trust me I’ve had more than my fair share. But most have been self inflicted and the great guys here on the forum have always helped me figure it out!

It works but I have to find the paths that are not working and move with this issue to make things better

Whoa! Never heard of a belt snapping before. You mean the belt broke? What happened?

were you able to check your grub screws on all stepper motors??

I did not but I do know that know I did the couplings but not the piece that moves the belt please confirm.

Lastly, it was the tensioner that broke ; just reprinted.

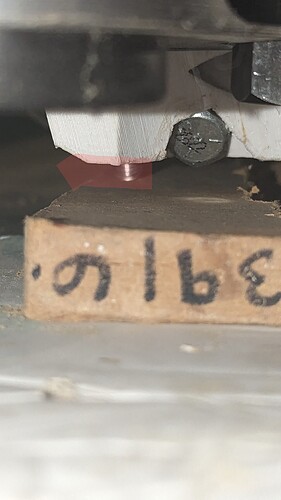

You need to check the grub screws on all of these as well. Both Y motors and the X motor. Also put blue loctite on these as well. One of the screws should be on the flat of the motor.

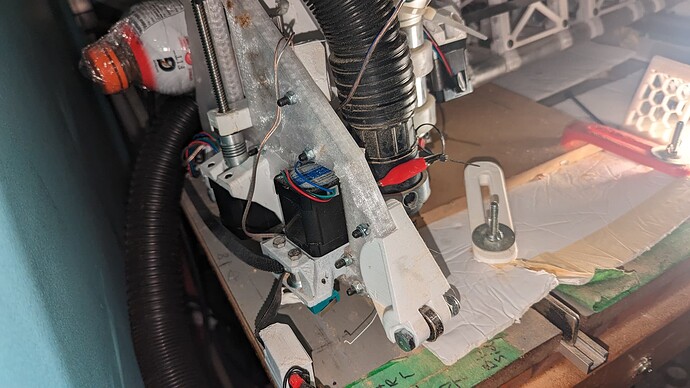

A bolt located on the bottom of the xcore is protruding out so far it’s hitting the stock and now lifts the back of the Y axis .

Again y’all thank you everything does function I’m glad I caught this

How do you even manage to do that? ![]()

I’m looking at my core. I don’t have any bolts hanging down at all. I think you have those in backwards possibly

As obvious as that was I was not really thinking much about that but is my biggest enemy at the moment i will keep yall posted ![]() smile:

smile:

Question how did yall get the nut in with the plastic not cracking that’s what I’m afraid of ?

You don’t have to push the M8 nuts into the plastic, do you? Just the bolts. The nuts are all accessible.