That’s too funny, though I don’t know how to fix it. ![]()

Guess I’ll stay with 11 a bit longer then… lol

Eh, it’s fine. It’s just a bit different. ![]()

Is it possible yet to add more designs at once, or is it still just 1 in EstlCAM 12? Once that works, or I figure out how, I would use it more

You can’t add drawings as far as I know, this is really a drawback if you’ve done so before.

While Insert drawing is one of the reasons I’m sticking w/ v11, using Update drawing after adding a new drawing/DXF layer to the project drawing does pretty much the same thing (both result in a new project layer). It’s not an option when I want to add an Inkscape drawing to an AutoSketch drawn project because Inkscape <> AutoSketch doesn’t work.

Hello,

I’ve removed drawing adding capabilities because this is better done by CAD programs and caused issues in some situations. CAD programs just offer much more and comfortable tools to edit drawings.

Try e.g. LibreCAD if you want to join dxf files and then use the “Update Drawing” function in Estlcam.

Christian

One of the great things about Insert is that it accepts SVG, e10 and DXF files. Being able to have reusable project files that can be inserted into multiple projects, e.g. for cutting keyholes, is invaluable. Inserting an SVG is flawed because it doesn’t use the embedded drawing origin (like it does w/ DXF), but it’s still easier and tidier (single editable source file) to use than any other option, e.g. no Inkscape save as DXF (and SVG) or importing/adding a copy to a DXF project using a compatible CAD program required.

Insert/Append also seems to be fairly common from other packages like VCarve, etc.

Not having Insert forces us to open CAD in order to do layout for that specific CNC program.

If I have a 4’ x 8’ CNC, every time I put a new sheet on, and decide what combination of cuts I want to cut out on that sheet, EsltCAM 12 now forces the CAM(job programming) to involve a CAD program purely for CNC job layout.

Opening up a CAD program and having to create an entire separate DXF just to place already modeled objects next to each other as an extra step in the process seems like it will become quite an annoyance for people who rely on this feature.

I’m not understanding how you are using Insert. Layout, positioning multiple DXF objects to be machined, is typically done in CAD. Editing, adding/removing objects to/from the current file/project is also typically done in CAD. Why do you need “an entire separate DXF” instead of editing the current project/e10 source DXF and using the Update function? Note: Adding/removing objects can be DXF layer based. The DXF can have any number of layers that can be visible/hidden, locked/unlocked, and deleted/restored in Estlcam.

The only time I use Insert is when I want to add an SVG or project/.e10 file to an existing project (.e10 w/ DXF source file). If I had a 4x8’ machine and was cutting the same things multiple times in various combinations/layouts I’d consider having a set of project files and using Insert and Move to position them. One issue is that moving drawings and paths is a two step process and not particularly easy. Having layers helps because, in most? cases, all but one drawing layer can be deleted. Another issue is that inserting projects into projects doesn’t always work, a stable tool list and reducing project tool lists (they are embedded in the .e10 and have no connection to the default list) to only the tools needed seems to help.

Look at it like this…

Lets say I have a library of small 3D models. Every time I print I might have choose to insert a different number of each of those 3D models all over my bed to fill up all my usable bed space in one print.

This can be done directly in the slicer. I can append as many of those models as I want, and lay them out as I choose before hitting print.

I see this the same way. If I have a library of all different possible DXF files that I can cut, I don’t want to also have to go make a new DXF file in CAD for every possible combination of layout of cuts I might choose to make.

Today EstlCAM 11 lets you do that. You can insert more objects and lay them out to fill out your bed space, make the program, and send 1 cut file to your machine. As far as I’ve read, other software like VCarve, etc. let’s you do the same. Lightburn does the same for laser files.

EstlCAM 12 forces you to insert another piece of software and an extra file on disk to accomplish the same task.

I get it, using Insert for relatively simple tiled layouts doesn’t require CAD. I hope you’ll try using/inserting project files (ready to machine versions of your DXF library) and tiling the paths.

It’s not just tiling the same design, but multiple different standalone designs as well.

That’s the issue. For instance, if I were running a business where all the products that I sell are smaller things, when I go to gather up my orders that need to be made for the day, it’s a lot easier to just lay them out in one program, as I could do in Lightburn with a laser cutter, for instance, rather than having to go into a more complicated design program just to shift things over slightly.

And then what happens if after you do that and save your DXF and import it into EstlCAM, you realize that something needs to be shifted over slightly?

In EstlCAM 11, you could do it right there by selecting only that 1 imported DXF shape and moving it to the right slightly for clearance.

Just seems like a bad idea to remove a convenience feature like that, while competitors still have it.

Moving objects w/ v12

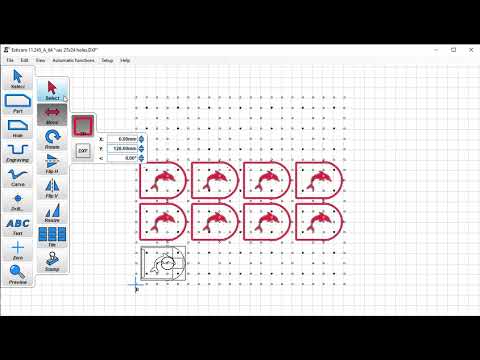

Example of using Insert for relatively simple tiled layouts. Both projects have unidirectional climb (t/r + b/l corners) and conventional (t/l and b/r corners) cuts which, last I checked, is also not possible w/ v12. Neither project can be done as a single project file because Estlcam doesn’t honor group level machining order. This is an issue in both v11 and 12, but it’s worse in v12 (multi tool pockets forced to the beginning of the program/G-code).

Hello,

enforcing strict group order for multi tool pockets would require at least 2 tool changes for each tile.

This would quickly turn insane - if you have e.g. 10 tiles you need to change and zero the tools 20 times.

If 2 tools are used for pocketing Estlcam must also ensure the larger tool finished its job before the fine tool starts - otherwise it would result in a crash.

Forcing coarse pocketing to the very beginning solves all those issues.

I also see no downsides as pocketing - usually - does not weaken the raw material too much - there is no risk of something breaking loose prematurely.

I see however the issue with the missing insert function - it’s clearly the thing causing the most complaints at the moment. I’ve added it to my ToDo list but like to complete a lot of other things first.

Christian

Nice you are listening to the users’ wishes. Thanks a lot!

…My comments were about Estlcam not honoring the project machining order. The machining order/number of tool changes for a single or tiled project is the same (machined individually unchecked).

I group all like tool paths and assign them a machining order. A carve is one of many possible project elements and all Carve paths (w/ same tools/properties) belong to one group. When I assign that group a Machining order it’s where I want/need that group to be machined.

I’ll work on a separate post about v11 and 12 forcing all other secondary paths (those set via path properties) to the end of the program/G-code.

While the forced machining orders may not be an issue for relatively simple projects, it can become a huge PITA when machining complex 2-sided projects.

The newest version has some really cool QR-Code features:

Also, the text editor is a lot better. And when I say a lot, I mean a whole lot. It was a pain to change some things with the old one and the new one is just great. Making the offset between the letters is really easy now so you can fit your text easily.

Kerning. The term you’re looking for is kerning. Very important for some words/fonts, like the word “flick” when using an all-caps font.

Yes, the 13yo me watched Barney Miller, and guess what the last name of one of the producers was, and the style of the font for the credits was? Now, think about how long ago that was (cops unironically wore plaid, BOLD PLAID, suits and really wide lapels), and what TV resolution was back then.