Whoops. It was looking so good too. Need to put down some painter’s tape.

I stumble upon this topic at least twice a day and I always think: Man, I hate feet. Quentin Tarantino would be into the topic.

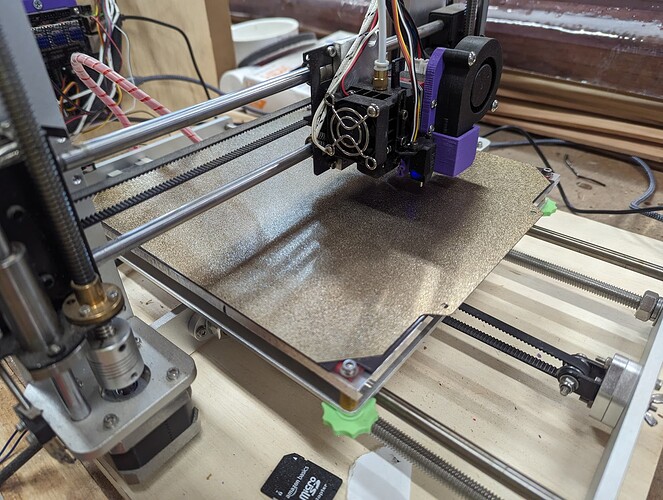

Picked up a magnetic PEI sheet for the print bed. It’s a 220x220. Current glass is 200x200. I should pick up some more printable space as right now I have to clear the 4 bolt holes and the binder clips holding the glass on.

Also hoping it helps things stick easier. I like the bed on my v4 quite a bit.

I have another friend that hates feet too.

I bought her these for christmas.

The pei sheet came in. I have the printer printing again. What I’m noticing is that the pei sheet on the bed heater does not provide very much support. I think I’m going to have to make an aluminum bed plate.

You can watch the Z axis move up and down from the bed leveling as it goes towards the sag in the middle. It’s kinda fun to watch.

Not easily. (sorry, missed your reply) Kevin basically just badly copied RRF’s pid tuning, but won’t make changes, or updates from people that do real pid tuning on multi-million dollar machines daily.

It’s another reason danger-klipper exists.

I guess I will have to check it out some more and maybe move one of my systems over to it and see if there is much difference. Will all the normal add on stuff work with the danger-klipper just the same?

Yep. Only thing I had to do when I converted over was re-tune the heaters.

Awesome. Thanks for the info!

Ugh. Went to print ASA on this printer yesterday. Klipper errored out that the heat bed wasn’t heating correctly before it got to 100C.

I backed the heat bed down to 80C, but the print detached from the printer.

So. I either upgrade the bed to 120V or I print a Petg core for the MP3DPv4.

Honestly, I’ll probably end up doing both.

Did you run a PID tune on the bed for 100º? I found that going to 100º on a 24v bed was not near as easy as with a 120v bed. It would take a LONG time to get there for sure.

This is only a 12v bed. And I’m only using the bang bang loop not PID.

Yeah 100ºc is a lot for a 12v bed

Yup… Too much to ask.

I went ahead and ordered a 120vac bed and another PEI sheet to install on top of it. I already have a SSR to run it off of. It’ll actually clean up the wiring on the machine a bit as I won’t need the 24v->12v converter that I’m currently using for the heatbed.

Not sure how much an enclosure helps get up to temp. My 12V Prusa seemed to do OK (with an enclosure.)

I think it’s the 1/4" aluminum plate the heater is sitting on that’s slowing down the heating process. I’m sure it would eventually get to 100c, but I think it’d take longer than the print will take to actually print. I do have the enclosure the printer used to run in. I may put that back over the printer.

Got the ac bed installed, levelled, and PID tuned tonight. Will try printing Asa again tomorrow.

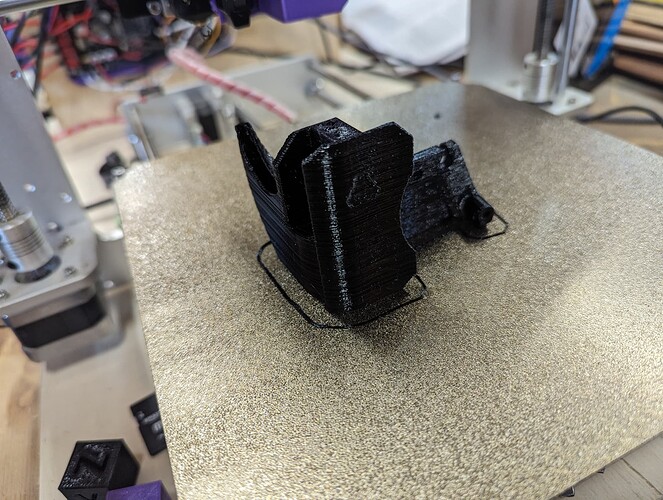

We have an ASA print… And the printer didn’t melt. I put the old enclosure back over the printer. Had to modify it a bit for the power supply.

After the print was done, I added a chamber temp probe. More out of curiosity than anything else.

The AC bed on PID kept the temperature solid the entire print.

Now I need to figure out how many of these little fittings I need to print. I know I need at least 12.

ASA on the left.