Thanks, was exactly my problem. I only seated them and didn‘t snug them up before. ![]()

That is very very high, 320in/lbs, 26ft lbs. If I am not mistaken I have 70in/lbs as the ideal for primo bolts.

That should not be an issue but if it is just rotate them.

The top bearing bolts should be seated, there is no adjustments on the core other than the bottom two that clamp.

Interesting.

Mike seems to have had the same problem. ![]()

They are not 24mm everywhere, but 23.8 in some places, so a little squished, so rotating does not help. It does not touch somewhere else then. But all good now. ![]() Thanks for all the help.

Thanks for all the help.

Whoops. It’s the lowest setting… ![]() Fixed that now anyway.

Fixed that now anyway.

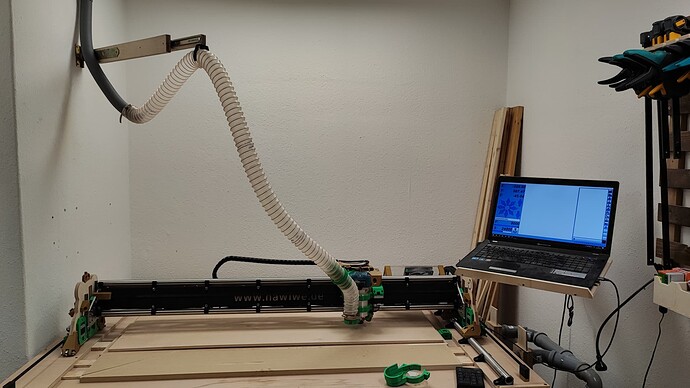

Next task: Get the vacuum hose out of the way (I ran it over yesterday, which lifted the whole ganty, when I paniced and pulled it away instead of stopping the program, Z dropped by a few mm and made a nice, diagonal cut into my spoilboard… ![]() ). For that I designed a part that can be screwed into my 50mm hose and, you might have guessed it, holds together with magnets. I can then easily detach it from the lowrider. Ryan’s design does not work for me because I need the detachable part just a bit over the second zip-tie. I hope it works. First version looks like this, with the thread being a bit to big. Still fits if you force it and nearly never comes off… Second part will have a lower profile thread.

). For that I designed a part that can be screwed into my 50mm hose and, you might have guessed it, holds together with magnets. I can then easily detach it from the lowrider. Ryan’s design does not work for me because I need the detachable part just a bit over the second zip-tie. I hope it works. First version looks like this, with the thread being a bit to big. Still fits if you force it and nearly never comes off… Second part will have a lower profile thread.

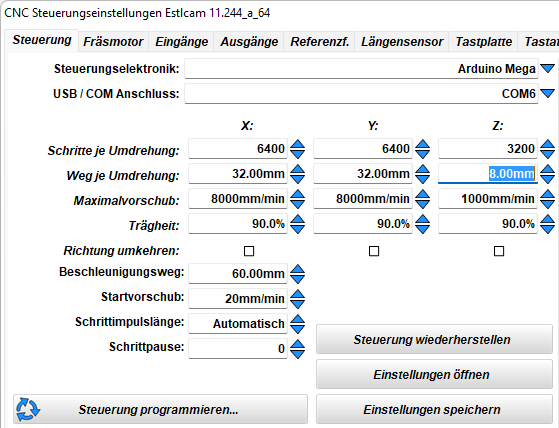

@Tokoloshe: what Estlcam settings do you use? I managed to get the x and y axis so work somehow (x10 = 1 cm), but Z is doing what it wants…

steps per revolution

distance per revolution

microsteps

A screenshot of the settings would be appreciated!

There you go:

And yes, 8000mm works for rapids if you set the inertia to 90%. I had it the other way round before at 40% because I thought it would break to 40% of the speed… Which isn’t true and I would have know if I had actually read the description of the tooltip. I had Z at 1500 before as well when I still had the mistake with the wrong percentages, it might work now again, but I didn’t try.

I don’t run any program at 8000 btw, I just have it set for rapids and it being faster when I manually jog it somewhere. ![]()

Three times is the charm. You get the hose on the second one, but getting it off is impossible without cutting it up. Third one is just perfect.

And now I shamelessly stole @Neilp’s ghetto design, telling myself this is only going to be temporary. ![]()

Lol, it won’t be temporary

Sorry for the absence: my parents in law lied about a test and came visit us anyway- and now we all have Covid. Day 6 for me. Sucks balls

Tjere is nothing so permanent as a temporary solution… so long as it works…

The last video went okay. I think for the next one I’d like to do an introduction to my LowRider and actually talk for a change.

Did you make an enclosure?

Enclosure using Extrusion/EMT + Metal/3D-printed brackets + 6mil plastic-sheet (maybe acrylic eventually) is on my list.

Look forward to seeing how the earrings turn out.

Nah, just an enclosure for the control board. ![]() The acrylic one. It’s been a while I actually used the CNC, was still finetuning the shit out of it.

The acrylic one. It’s been a while I actually used the CNC, was still finetuning the shit out of it. ![]()

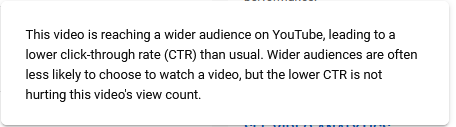

Well, that’s new:

Does that mean YouTube pushes that video to more people to see what the target group is? Pretty interesting. ![]()

Wow, that is differnt

Yes, exactly

You might have a top performer for your channel there

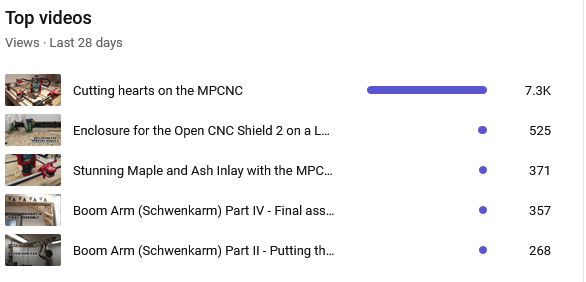

The top performer is still a video that completly sucks. It was one of my first, nearly unedited, of sth. my wife asked me to do. Just cutting out simple heart shapes. 31k views. Really annoying. I upload a video of trochoidal acrylic milling which gets like, 525 views in a month, whereas the stupid heart video racks up ~7.3k views each month. Kinda frustrating… ![]()

That’s because the audience for troichoidal acrylic milling is way way smaller than that for others non-niche applications

I had an aquariums channel a few years ago. I once got 78k views on a video showing my pistol shrimp eating a piece of poop. Meanwhile- entire videos of equipment and aquariums builds, and walkthroughs of the corals etc get 60-80 views Total.

I ended up not posting to the channel any more after the move 3-ish years ago and removed most of the videos, because I was seeing people on tik tok and YT ripping them off as shorts and getting 120-200k views. Really annoying.

I’ve got a timeline to get my woodworking channel up and running by June. Going to drop 5 vids at once, and do 30 shorts in 30 days in the lead up to it. We’ll see how it goes

I just subbed to your YT and watched the earring inlay vid. Sooooooo nice.

Remind me what software you are using for the inlays, please. It’s about time I did one. I have materials I can use, no excuse. I might try the bee in maple on walnut

Thanks