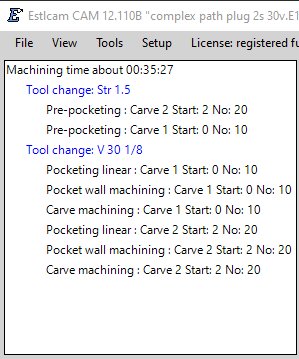

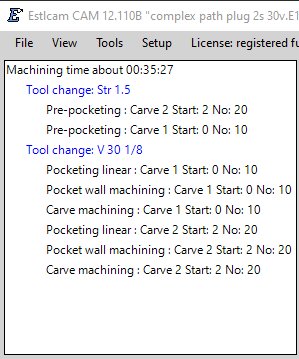

I’m not sure I understand the multiple programs, but manually editing is required because Estlcam is doing the Pre-pocketing out of order, e.g. Start level 2mm/machining order 20 before Start level 0mm/machining order 10.

I’m not sure I understand the multiple programs, but manually editing is required because Estlcam is doing the Pre-pocketing out of order, e.g. Start level 2mm/machining order 20 before Start level 0mm/machining order 10.

EstlCAM always does the clearing toolpaths first, then the V-Carve. Other programs do it the other way round.

Normally you don’t need the multiple programs, only if you want deep inlays. ![]() You need the multiple programs for multiple starting depths because noone wants to cut 9mm in one go I guess.

You need the multiple programs for multiple starting depths because noone wants to cut 9mm in one go I guess. ![]()

You could go infinitely deep (w/ a single program) if the Pre-pocketing was done in the same order as the Carves, e.g. 2mm deep (0mm start) > 4mm deep (2mm deep w/ 2mm Start)…

EstlCAM will set the machining order to the “best” (shortest) order by default, and it can have some unwanted results. You can set the machining order to do it in chronological order (order that it was defined in the program), or you can select each element manually in the order that you want.

If you have one or two elements, the manual method works fine. If you have dozens, I have learned to select the elements (individual holes, parts, carves, etc.) in the order that I want them cut, then select “in order” as the machining order.

Yeah, but no program does that automatically. In V-carve you have to adjust it manually, in Estlcam it is not possible to adjust the pocketing and carve individually, they always go together. I asked Christian about it and he said he wouldn’t include the feature because it might be confusing for new users.

So we are back at making three programs and pasting them together.

If you have an easier solution I’d really like to hear about it. ![]()

I went over to just run the pocketing toolpath in all three programs and then change to the V-bit only on the last one so I don’t have to do the whole copy-paste stuff.

The point is that the Pre-pocketing is not done in the set machining order, No: 20 is machined before No: 10.

As I said before: Estlcam does pockets first, then carves.

F-Engrave does Carves first then pockets.

It does not matter. ![]()

Common guys, wake the f up, pockets first is fine. The issue is that the pockets are machined out of order (not in the same order as the carves are machined). It’s only logical that the specified machining order should be applied to both the carve and pocketing path groups. Those pockets being machined out of order is the only thing preventing single program (any depth) carved inlay plugs.

Eh, no. You can easily say that the depth is 8 mm for the plug and do it in a single program, but then the plug won’t fit. You need the starting depth because there is no way of calculating the plugs besides cheating the program.

And Estlcam does not care about what order you’d like but goes for fastest machining time. You can still make it a single program with a little manual editing. I also do not get how the machining order changes the way of there being the possibility of a single program. Would you mind to elaborate on that?

Also I don’t get why you are so mad. I am one of the few people here who have done deep inlays for cutting boards successfully. I am not against learning anything new, but the point you are making does not seem to be relevant at all, so either I am really dense or you are wrong.

The only thing I can do at this point is to try rephrasing in the hope that it will help explain what I’ve already posted. An important point is that you can create a program that machines everything in the order you want it to be machined in by giving each (Group of) path(s) a machining priority (the No: field, typ. 10, 20, 30…). The exception is secondary paths, paths you set via the primary Path properties window, e.g. pocketing, chamfering, etc. Estlcam forces all (but v11 carve pocket) secondary paths to the end (v11 and 12) or beginning (v12 carve pocket) of the program which can limit Estlcam to relatively simple, or multiple program file, projects.

Having the pocket tool group at the beginning of the program (v12) is fine for carve pocket plugs. What is not fine is that the default pocket tool group machining order is not the same as it is for the V-bit tool group and specifying a machining order doesn’t help… After changing as many things as I could think of, the only constants are that the V-bit group machining order is honored and that the pocket group machining order is always the opposite of the V-bit group machining order, i.e. it’s a bug.

About the program Preview image (above):

V-bit group is fine, Carve 1 removes material down to the Carve 2 Start level and the machining order is honored:

Pocketing group as is, Carve 2 is diving through uncut material that needs to be removed by Carve 1:

Pocketing group as it should be, Carve 1 removes material down to the Carve 2 Start level (same as carve group):

P.S. The purpose of my Finishing pass with 2D Carve? - #22 by dalrun post was to try to show how Carves are 100% Z based and that a negative Z offset/Finishing allowance cannot help with carve pockets because they are a combination of 2D pocket (X,Y wall) and 2.5D carve (Z wall) paths. Using a Start level Z offset is the only way I know of to calculate/create a carve pocket X,Y perimeter offset.

Okay, let me sum that up: you want to combine both toolpaths with different starting depths in one program but can’t because of the machining order of the second carve?

@christian-knuell any reason why it changes the machining order of multiple carves?

Like Dave says: it’s cutting pocket 1, pocket 2, then carve 2, carve 1. So stacking carves for inlays in one program does not work.

I edited my last post to be more descriptive/accurate, The Carve 1/2 paths are split into a pocketing tool group and a V-bit tool group (fine so far). It’s that the pocketing tool group path order (Carve 2 > Carve 1) is always the opposite of the V-bit tool group path order (Carve 1 > Carve 2).

The V-bit group contains the primary paths, paths that can be machined in any order by setting the N0: field, e.g. Carve3 No: 10 > Carve2 No: 20 > Carve1 No: 30. As is, the secondary pocketing tool group paths will always be machined in the opposite order, e.g. Carve1 > Carve2 > Carve3.

That’s a great observation and it could really make things a lot easier (even the way it is now) because I have no problem cutting the three pockets and then doing a single deep pass with the V-bit (that’s what I am doing now anyway because I am lazy) and then just stop the program. ![]() Good find, thanks! Will try that with my next deep inlay.

Good find, thanks! Will try that with my next deep inlay.

This appears to be fixed in v12.123, i.e. both the pre-pocketing and v-bit tool groups are in the correct order.

Ok, I read and re-read this topic. I’ve got a ‘project’ my wife challenged me with for a family wedding project. She was interested in me doing an inlay.

When I set things up in EstlCam (v12.153C), the female part works out good. The male (plug) part doesn’t seem to get into the ‘B’ as you can see in this screenshot. The carve bit is a 30 degree bit and I selected the 1/16" bit as the pocketing tool. This is the smallest I have thinking it would be able to fit inside those curves to clear out those parts. Is my font too ‘pointy’? The smallest gap I see is about 2.9 mm. Is this not working because I have the ‘diameter’ of my 30 degree bit set to 6.34 (which is the diameter of the shaft it is on)? I wasn’t sure what the depth of cuts should be for the project, so I just came up with shallow ones for now. I figured to learn, I’d use these to do a cut and then see where I went wrong with them (if I did at all).

You need to program several carves. Carve inside on the square, carve outside of the letter. Estlcam then combines those. ![]()

Ah! Thanks. I didn’t think on clicking the other mouse button ![]() . When I do it works.

. When I do it works.