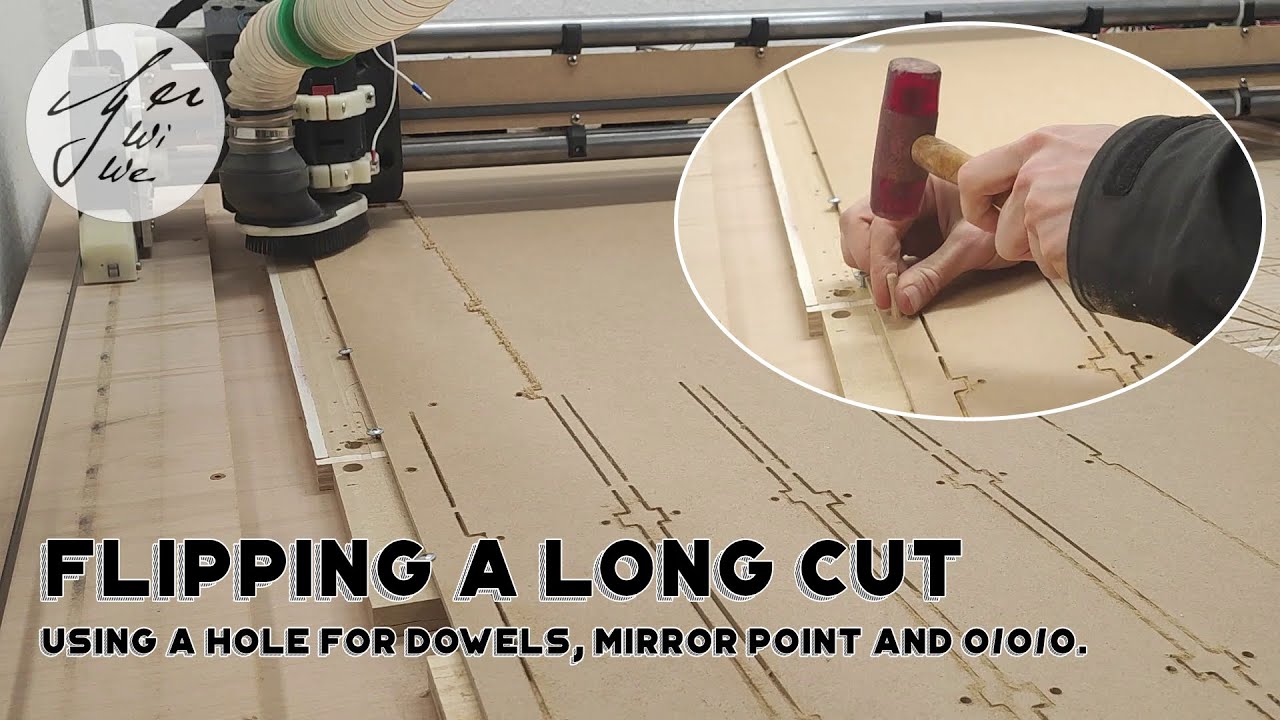

This video is not dealing with how to create the toolpath, just with the machining part of the process (though the toolpaths should be obvious after watching it):

In the video you say that “Estlcam remembers the 0/0/0 of the previous program and the current coordinates”

Trying to understand the use case as I think it could be helpful to me as well.

Does this mean, that in your first cut file it sets 0/0 on the X and Y with G92. After the first cut has run its course, you can move the machine wherever you want to be able to flip your piece. Then on cut two G92 and all that is removed from gcode and it just goes straight to the first cut location of the file?

And if you needed to do a tool change you would just add the gcode for probing and thats it. You could probe anywhere on the piece after the first cut, and the second cut would just go from there, back to 0/0 that was sent in the first file?

Thanks!

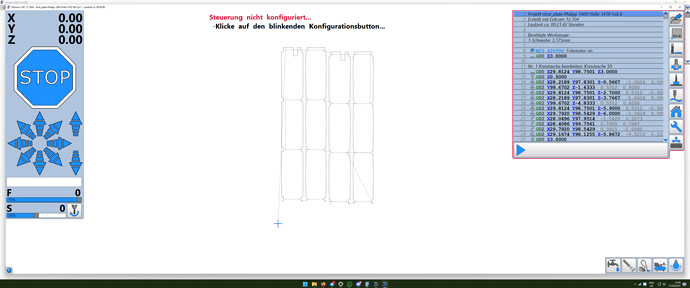

You set the 0/0/0 in Estlcam manually before you run the program, Estlcam remembers the project coordinates and total coordinates. If you set them to 0/0/0 it will always start at those coordinates until you set new ones (mostly that’s changing Z), remembering the last five starting positions, even over a reboot and complete disconnection from power.

In between I can jog the machine wherever. I can also pause the gcode whenever I like, jog the machine anywhere, add a screw or whatever I wanted to do and resume the cut. It then goes back to where it left off. Same with tool changes. I jog it anywhere and then either resume (which would be stupid because the Z changes) or either manually set Z or push a button that I want to use the touchplate. It’s not in the code itself. And yes, if I only change Z, X and Y stay the same.

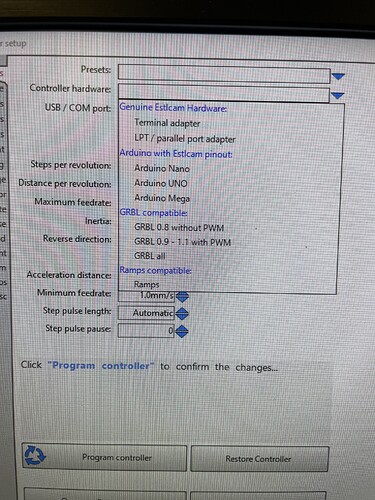

Ahhhh maybe thats the difference. You use Estlcam as the controller as well, correct? Im on Jackpot/Fluidnc

I don’t really know how I’d do that on Fluid. Maybe home, jog to the starting point and write the coordinates down? Then on the second program, home again, jog to those coordinates, set 0.

Nope. If i have it correct, his dowel holes are in his dxf being imported to estlcam! So he zeros to midpoint on the dowel hole.

So in estlcam you simply flip the drawing just like you do on the table. Now here is where i will need to remove my probe on the 2nd gcode! You can move negative and even cut negative, so i think i completely understand and it helped immensely!!! (I think, bahaha!)

The first program actually cuts the holes as well, that’s easiest. ![]()

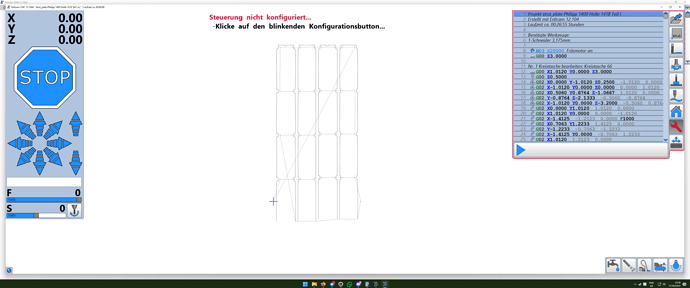

Don’t be confused by the red writing, this is my home computer which does not have the CNC attached. The one in the shop does not have blinking buttons. ![]()

Yeah as i was just thinking abiut this i think i can zero from the holes in the strut!!

Yes, you could but they do not fit a dowel. The dowels are essential in setting up the cut exactly like the one before and need to be 0/0 again.

I have a 3d printer to make a pin to fit that hole ( ![]() )

)

Feels like cheating, but okay… ![]()

Just for clarity:

ESTLcam can be used two ways: to generate a GCode file, and to control a machine.

@Tokoloshe uses it both ways.

I’m not positive, but I think his statement about it remembering the 0,0,0 is a reference to the control side.

Also, the FluidNC based control options, which work on the Jackpot control board, also remember the 0,0,0 workspace coordinates, not only between jobs but even after a reboot.

Thanks for making this! I probably would have tried it if my struts didn’t fit diagonally. But definitely will use this method in the future!

I ruined something very expencive at work once doing something similar. ![]()

Edit. Soon after that boss ordered machine that was capable for 2x3m cutting area ![]()

I am a little mad. My Mononoke video, which took hours of cutting, editing etc. gets like, 750 views in 3 months. The stupid LR4 aluminium video gets 2.1k in 10 days?

Star Wars Coasters - 226 views in 2 days… Flipping a workpiece? 15 minutes of editing… 250 in 22 hours. Like: Why do I cut cool stuff when all you guys do is come for the explanations of stuff? ![]()

![]()

/edit: I am not seriously mad, I just find it interesting what is interesting to an audience and what is not. ![]() Heathens.

Heathens. ![]()

If it makes you feel any better, I watched all of them.

And if you made a video of nothing but your CNC cutting things at normal speed, including the loud CNC sounds, for 10 minutes straight, I’d probably watch that too…

But, to be fair, if you made a video explaining something I needed to know, I’d probably watch it multiple times ![]()

Marking you down as #1 fan. ![]()

In all honesty though, there are a few videos I have watched several times about inlays until I understood how that stuff works and was able to find a method that works with Estlcam (they all use V-carve where you can program it like I do but then switch the order of the cuts around manually, it’s a lot easier but 700€ more… ![]() ).

).

Entering old man mode now: Back when I was still playing with my band we had three people come to every concert: one guy a year below me at school who liked it, a friend from my year and Die Abgehfrau (our nickname for her, hard to translate). She was always there, every concert, dancing to our weird psychedelic jazzrock. We really digged her and gave her the first signed copy of our CD when we released it. Last year I met her, she works at the library. That was nice. ![]()

Hahaha yeah I watched this one in the morning at work. And wanted to comment so I had to log on.

Thanks again for the videos.

I was excited for a bit there and thought maybe the new estl cam was accepting the lr3 boards now.

It seems like such a great tool for the router movements.

I don’t think he is ever going to program it. Did someone officially request it in the forum? Christian is here, after all.