So nervous of how hard it is going to fail at those speeds!

Fwiw, here is the end mill I used…

It has lasted for years of light use… has certainly paid for itself at this point. Even after torture from drag race runs, it still cuts like new. It is a top quality brand, and a config that is just about ideal for this.

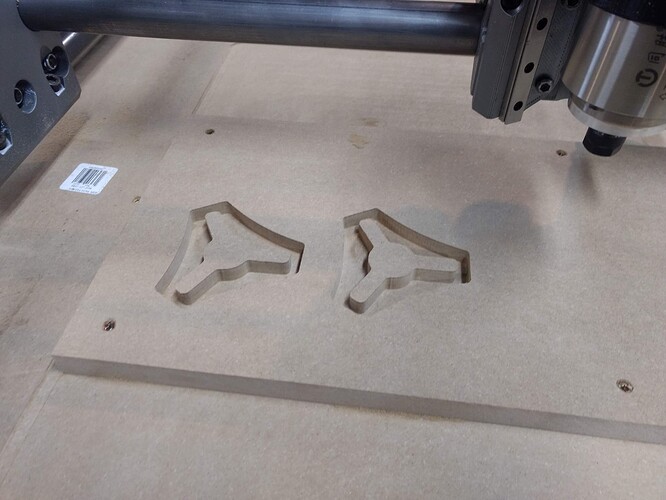

I raised the firmware limits, went to an 80% stepover. 55mm/s cutting, 12mm DOC, 22mm/s plunge, single flute 1/4" single flute endmill.

39 seconds.

Dimensions finally started to really suffer. XY is within 0.54mm, the Z was fine but one corner was 12.7mm deep. I think the board is warped or maybe the router got pulled down, the other two were 12.17mm, 12.12mm.

Video is uploading now.

That is really very fast. It seems like it is really similar to some of the much larger cnc machines, like the ones in the wintergatan videos.

Size matters. I think. My mind is blow that this is shredding this MDF like no big deal, so I am doubting all my previous years of assumptions.

This is one of those things that is going to be interesting to see what sort of speeds larger builds can achieve. Mine has not failed, so at what size it this not going to work?

That’s amazing, so great to see @barry99705 and others set the bar high and it keep getting pushed.

What sort of acceleration values are you running, Ryan? Given the cut speeds you are running all of the cornering seems ponderously slow in comparison. Yes I know you are shifting quite a bit of mass, but carrying a little more speed through the corners (at least on the roughing passes) could shave off a few more seconds.

Stock accel. It does look slow in the video but if you see it from the top it works out really well. This is a 80% stepover so when it comes into those tight corners it is almost completely buried. The router takes a serious hit, I almost wanted to slow them down a bit. I think If I put the 660 back on you would hear it slow.

I’m pretty sure your shop vac was useless in that last video.

It is soooo much worse without it. It just spews MDF toxicity everywhere without it, with it, it only goes 180 degrees and a lot less in the air. I do where a full respirator while making these cuts.

Yea, mine was doing that too. Still, the dust collector got a lot of it. My laptop wasn’t totally coated.

What software is that? That does not look like estlcam.

It is from the milling basics page, here, Milling Basics - V1 Engineering Documentation

Well, quickly hit the curve processing ability of the rambo 1.3, Archim2 in the mail! 1/4" 2 flute endmill, 50mm/s feed (gets there on the straight lines at least), 12mm DOC.

Turn on arcs, shouldn’t be an issue anymore.

Sadly the first vid is with arcs on, at least with them off (second vid) it wouldn’t pause.

How do you do that?

Arc support must be enabled in your Configuration_adv.h file and you’ll need to build the firmare.

For recent versions of Marlin (2.0.6 and above), you can send an M115 to see if your firmware has ARC_SUPPORT enabled. For earlier versions you can send an empty G2 or G3 command. If your board responds with unknown command, arc support is not enable.

So if i used the latest fw from this site, is it on?