All the current firmware have supported it for the last couple years, you need to make sure your CAD program has them on. In Estlcam, and the marlin basics, I have it highlighted where to turn them on.

Oh ok. I will check. Thanks.

Rechecked my FW, it is definitely on in there. Was on in Estlcam until I turned it off for the second run.

What firmware version exactly? I know in some older ones arcs were iffy, but I thought it had been fixed.

I had random short pauses in operation when I was using an MKS Gen L v1.0, which is a Mega2560 based board. That was one of the driving forces in getting me to upgrade to the Duet Wifi. Faster processor, no more pauses while cutting arcs and circles.

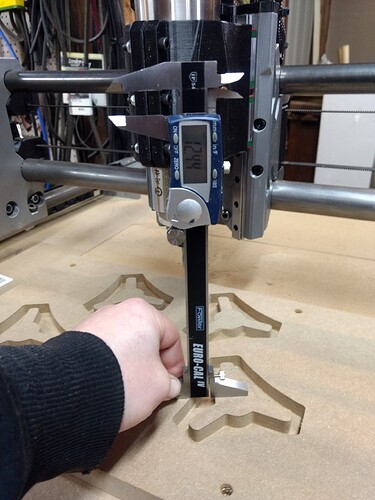

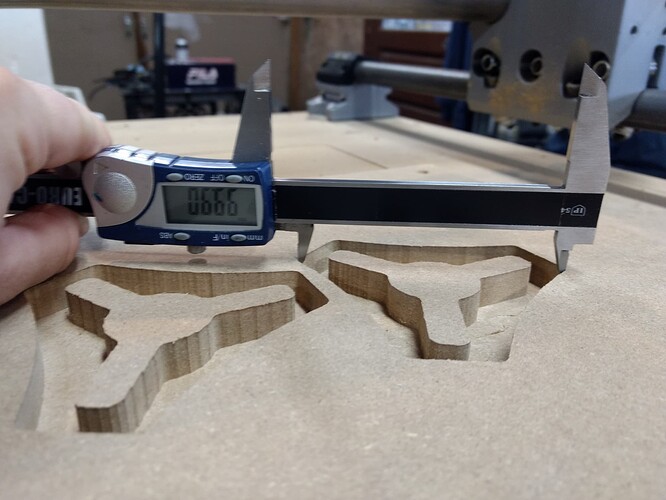

Speed is up to 80mm/s, 200mm/s^2 accel for x/y. Tried F360 this time around to start learning it, wound up at pretty much 40 sec for the cut. Starting to lose some z steps when it bites in hard, might have to try upping the current some more or just play the waiting game for the other lead screws I ordered to try. Measurements are from test 5, still staying really close to the others back to the first run for x/y. Safe to say the Archim2 and 24v psu definitely didnt hurt.

Looks good!

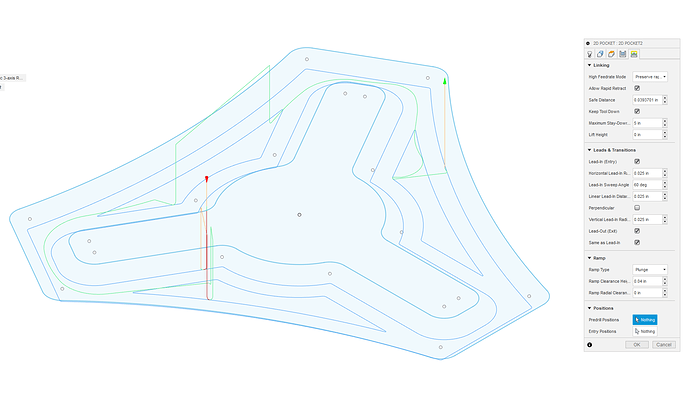

On fusion, on the second to last panel (or maybe last panel) of the tool path, you can set “keep tool down”. That should keep it from going back to the safe plane between cut moves. Might only exist in 3d tools, i can’t remember. But that’s more easy time to catch.

It is under the last panel and it is selected, but it still insists on those retracts. Did set it to just plunge instead of a helical ramp. If anything I’ll just have to brute force the speeds and accels instead of working CAM magic to beat Ryans time

Better do something, my 2’x4’ LR3 does 40 seconds without much trouble in the exact center of it’s work area. Cleaning up some wires and hoses to try to get that a bit faster.

I think it might be that it’s a 2d path. Fusion doesn’t know where it can travel over what selected pockets. I don’t know if it violates the rules to extrude it into a 3d shape and cam off of that.

@vicious1 Rule check? lol

Any means possible to get the fastest cut. I hand edited the gcode linked above to get rid of my Z moves!

We will need to revise the race to depend more on cutting than moving though. The 16min cut came down to :39. So time to make it bigger or out of metal.

Raw speed it is for now then

Went and tried one last run before I switch to doing my own projects for testing. Went to shave a couple seconds off, and I managed to do just that!

Can penalize me a second for missing the plunge some how (apparently hit the start program button too quick after hitting record on my phone XD). 100mm/s feed with 500mm/s^2 accel X and Y, 30mm/s feed and stock accel on Z. Switched to a 3 flute end mill (.25" dia .75" loc) since the 2 flute was loading up too much at 80mm/s.

Amazing!