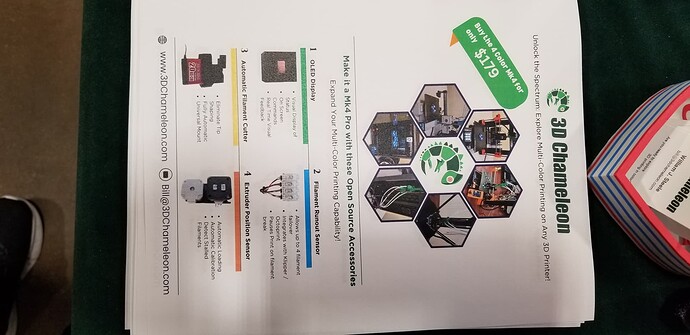

Short: https://www.3dchameleon.com v4 officially releases April at RMRRF 2024. Seems like a time and cost effective multi color/material solution? Some auto calibration added to mk4. Isolated components so no need to add switches/steppers-driver to your Printer’s controller board. Each 3D Chameleon supports 4 to 1 switching. Can daisy chain and combine to support switching up to 32 colors/materials… FAQ

Long:

Anyone happy Chameleon v3 or v4 users? (Known as Chameleon MK3 and Chameleon MK4, similar naming to Prusa).

Chameleon’s been mentioned a few times recently, e.g while chatting about ERCF https://forum.v1e.com/t/ercf-enraged-rabbit-carrot-feeder/39595, by @Jonathjon and others. So, dug around…

Chris has great overview and assembly walkthrough… Chris mentions bunch of tips throughout that seem helpful to ensure a successful working build.

Price for material and labor to install (“Less than 1 hour to install” claimed on website), seems more attractive than ERCF v2 given am not able to find any v2 kits yet.

- Print the Parts (Chris recommends PETG) Printables

- Channel, infrequent updates, https://www.youtube.com/@3d_chameleon

- From https://www.3dchameleon.com…

- $179 + shipping/taxes

- “Less than 1 hour to install”

- “Recent videos are talking about the Mk4 3DChameleon. See our FAQ page for details on the Mk4 and when it will be available. In short, the Mk3 that we are shipping right now is the identical hardware to the Mk4 base unit. The Mk4 will have additional optional accessories and new firmware when it is officially released at the Rocky Mountain RepRap Fest in April, 2024.”

I’ll confess, there’s some multicolor kitschy things I’d like to print. Mainly just as a ploy to get the family interested… However, am hoping to mostly use for multiple material functional/utility parts.

The relatively non invasive design seems very smart to me, can add to almost any Printer, MK4 firmware’s uses TMC sensorless homing features, detect rise in current draw to auto detect where filament is. So, latest firmware should be much easier to setup and auto calibrate.

So many technically great things. Assuming it works great, my biggest issue is with the color and shape of the green Y part. Hopefully that can be printed too.

If you wanted to add bang-for-buck multi material capability to your existing printer, while considering material and time cost, then, would you get this or something else?