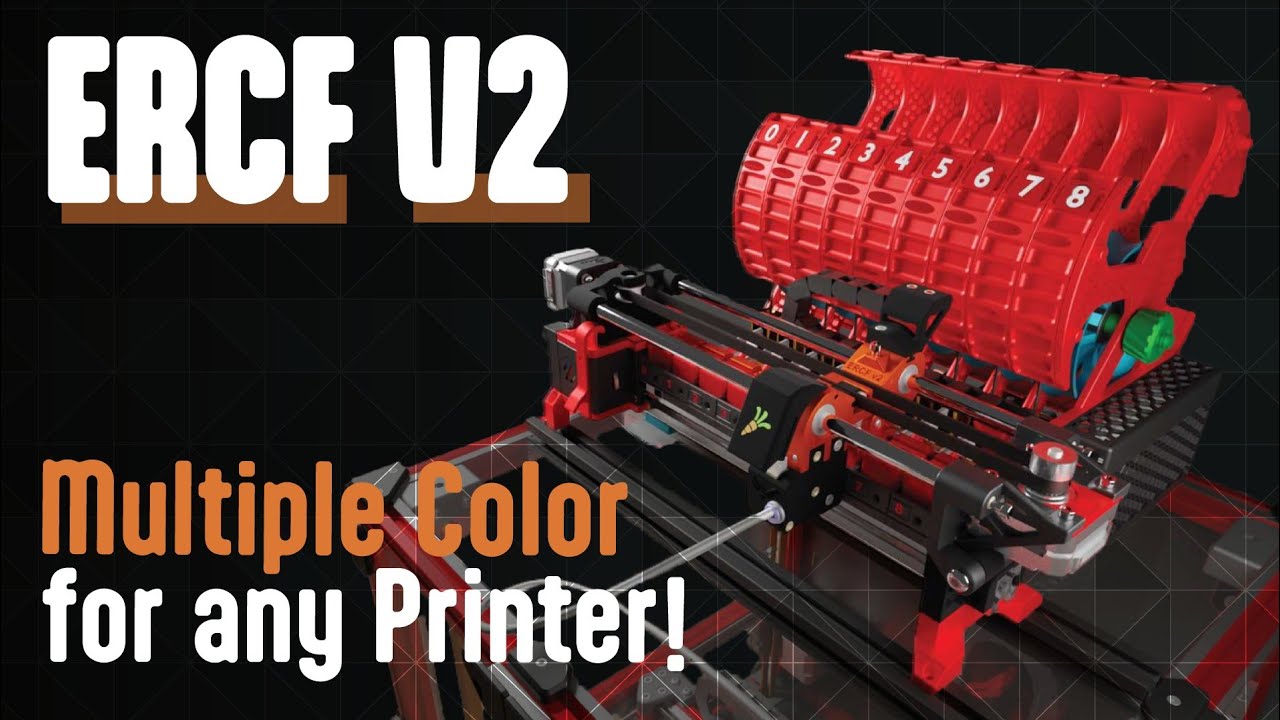

Anyone using it yet?? I just found out about it. Looks awesome. Does use material on changes but looks fun, was it worth it in the long run? Looks like a year ago it came out. Cannot believe i did not see anyone with it at mrrf!! Video for reference of what i am talking about!!! I find too many things i want but cannot afford dang it!! https://youtu.be/HBFqRk-nMfM?si=7-wlWSLfY0cBIC0z

I don’t know the differences but it looks a lot like the Prusa MMU?

Just found this u r correct!!!

The ERCF was inspired by the Prusa MMU2 and the Smuff

I have a MMU2 and I really like it. I have to say though in the price bracket of a mk4+mmu or voron+ercf I think I’d honestly find it hard to overlook a bambu and AMS

Well, the ercf can go on to anything, it has klipper code. But I although i really like what it can do. I cannot justify it right now. I only found it, because i got notice of a board that Bigtreetech said would work great for it!

Stumbled onto Enraged Rabbit Carrot Feeder v2 RC1 (released Dec 2023)…

More info at GitHub - Enraged-Rabbit-Community/ERCF_v2: Community designed ERCF v2 , different group than original author GitHub - EtteGit/EnragedRabbitProject (last update ~2yrs).

Still trying to tell if this is a legit approved v2… Interesting either way.

“This is a community-born project and a major update to the Voron ERCF MMU that was started a couple of years ago by Ette. It is endorsed by Ette, and the guiding philosophy wasn’t to start again with a new MMU design but to refine what has already proven to be a very capable machine and push it to be the best it can be”

From what I can tell, the original ERCF creator is no longer actively doing anything with the original

Saw that, but didn’t stumble onto Ette’s actual endorsement on GitHub - EtteGit/EnragedRabbitProject, closest I found was a recent pending pull request. Not seeing @EtteGit in ERCF_v2/contributors either.

Yeah, O.G. project looks stale.

That is too bad! So easy for something to go stale anymore! I read something and cannot remember the number, but it was the number of stale projects on github!! It was astonishing! Github does not prune do to dependencies. But this project seems like one that would continue on.

That looks a little more complex than I thought. Feeding in the filament looks tricky, bit I still want to try one.

The 3D chameleon looks to still be getting pretty active dev as well. Seems a bit easier if you just want 2 colors.

A 2 color changer would be useful to your production flow for something like a part with a translucent material in the base and then an opaque material above it. To let through the light on a Kobalt router in its’ mount, as an example.

Beyond the simple two color option, ERCF2 looks like. a good expandable system.

Something I found when working with friends’ MMUs on Prusa printers is just how much time it adds to the print to do all the required material swaps. A 4 color change at every layer on a moderately big print can add days of processing time to the job. Maybe it is better on the new MK4s- but this was a real surprise.

Something worth considering- one problem with changers is that there are some significant material incompatibilities. Switching between PLA+ and PLA, or Silk, or some of the other difficult PLA formualtions can impact a print in unpredictable ways. Mixing PETG/PLA isn’t just a thermal issue, for example, the contamination is a nightmare. Dissolvable fillaments are similar. Not just in one print with these materials but even switching. between jobs. There’s plenty of reasons to want to use a rigid material with a flexible material, but those can be difficult to overcome material incompatibilities.

There’s an argument for an extruder toolchanger option, or a simple dual extruder on the carriage where one goes to a changer like the ERCF and one has the incompatible material like say a dissolvable support. Certainly not something to be in the baseline printer, but as optional enhancement that isn’t completely impossible to add on.

I know your designs are remarkably printable without supports, but there are plenty of hobby and many engineering prints that just require supports or they don’t work.

MP3DP exists first and foremost to scratch your itch for a reliable print farm machine and I respect that.

Just leave an option if possible for that bit of tweaking that comes about as the rest of us hangers on to your design customize it to scratch our own itches.

A tool changed would be the cream of the crop in my book. At that point I would seriously consider a Bowden system. Swapping a nozzle only seems like it would be significantly easier, and take up less room.

If Jamie can rig up a router tool changer, I am not against a printer tool changer.

I think the fundamentals are some extra room beyond the bed, good locating system, and some sort of automation for a lock (servo).

If people think this is important, we need some design proposals so we can make sure the base model is compatible.The standard can be a solid mount and the fancy people can use a changeable.

Man just callin folks out like that… what a shame LOL

I have been looking hard at the ERCF V2. Mostly just waiting on a good kit to be available so I don’t have to try and self source all of the parts. There is at least one part that is custom made for it, yet still open source. The way their system ties into klipper is real slick. I don’t even care about multi color, I want endless spool lol.

One of the big issues with the first ERCF was you had to have the retraction tuned perfectly so that the end of the filament was formed just right. Pretty much if you didn’t have a revo you were going to have problems. But the new version gives the option for a filament cutter at the tool head that elevates all of those issues according to the docs.

So would the hotend always be hot? I would think that could lead to filament burning waiting to be used?

I think on the tool changers they cool it down and heat it back up when you change to that tool but I’m not really sure. Now I’m curious as well LOL. I’m sure its something you can set yourself in the firmware/slicer but I could be completely wrong. Seems if you knew you were going to be using toolhead A and C for instance that the firmware/slicer could set a standby temp of say 150c on the toolhead not in use so that it would be mostly ready when it was its turn. But this is all me guessing LOL.

I have klipper, so i could configure it somehow i am sure

The more i think about it, like it. Because each filament, unless identical, will have its own properties. Now my problem is i use microswiss dd units. So idex would be needed. Hmmm. I have 2 printers. (Mad scientist ideas are swirling)

I do not have core xy, can you do idex on it?

This is where something like the 3d Chameleon would shine. Very simple I can’t see why endless spool would not work the same way and I am pretty sure it also uses a cutter now.

Really depends on what you would want it for.

I want endless spool, and occasionally clear for the tool mount first few layers. I would not need a wipe tower and only one filament change.

I see how having tons of colors would be cool I just never do that type of decorative printing. Best case I would just add colored logos and highlights at the expense of a ton of time.

Not that I know of you would need a traditional style XY like the MPCNC. The tradeoff is you are always moving two extruders, so you lose speed 100% of the time. The advantage is you could print two identical parts at the same time if you wanted.

Yeah I watched part of a video from Chris’s Basement the other day about that setup. It just seemed so fiddly to me but I didn’t give it a ton of time and have done zero research on it. I saw the headline for another video talking about it last night but didn’t watch. I need to look at it more. I tend to go for the one that’s the most out there because you tend to get a lot more and a lot better community support that way. This is the first I have ever heard of the Chameleon and apparently its been out for a few years.