I think we need a builder of each, figure out the likes and dislikes then smash them together and make a style.

This is the only kit I know of right now, but the ERCF v2 kit is significantly cheaper than that at $160 from SIBOOR for 8 colors

The 9 color orginal ERCF appears to have been a similar price from FYSETC, but is now discounted down to $105, I presume since the v2 is out now

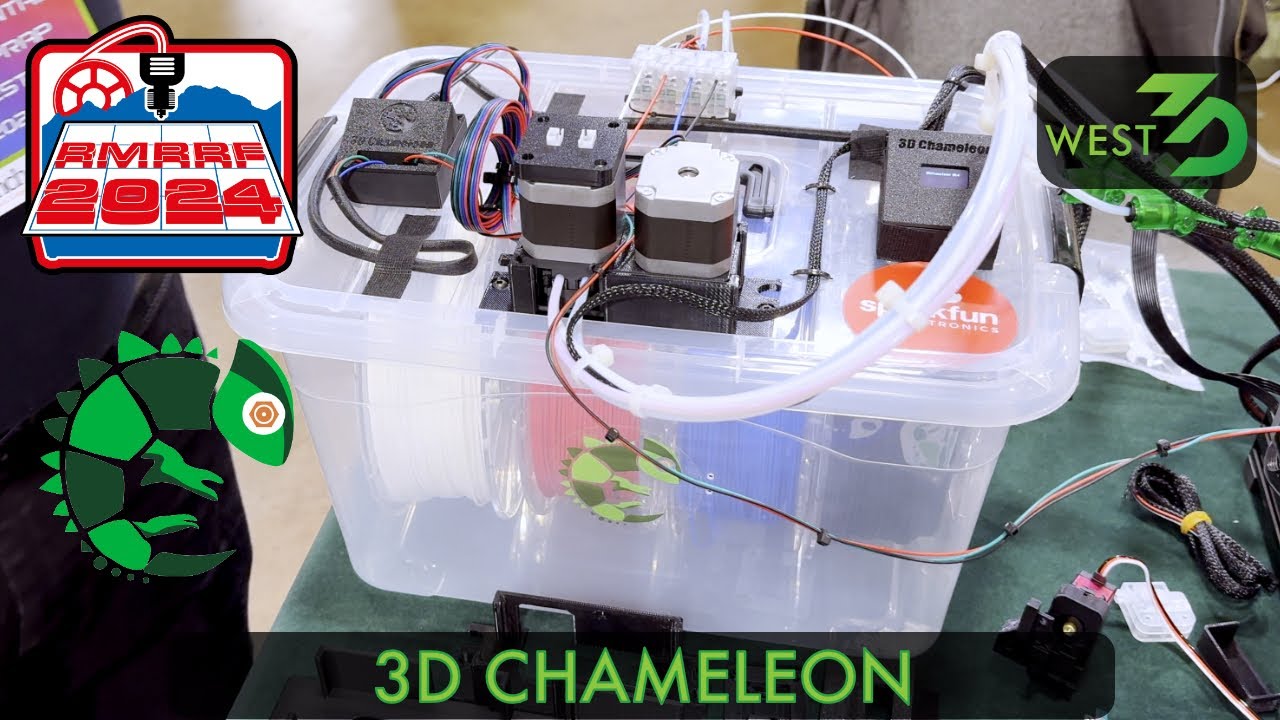

(I don’t know that much about either the ERCF or the 3D Chameleon, just have looked into price before)

I guess I’m your ERCF Huckleberry lol. Ordered the Siboor kit about a week ago.

this is the kit I got. From Aliexpress though

I will start a build thread once I get started. Have to finish the panels for the V5 and do some ABS testing first. Never printed ABS before so we will see how it goes lol

Briefly looked into ERCF v2 a few months ago, but was dismayed by the total labor/assembly time involved (e.g. LeeMerie3D’s very useful, but long multi part build series), and, the frustration people were sharing at that time. Total labor+material cost is what pushed me towards Chameleon, back then, and for now…

Was hoping, and still am, that ERCF Community driven kits/designs will improve over time to reduce time and frustration to assemble, and to tune/troubleshoot… Looking forward to seeing other’s Chameleon and ERCF v2 experiences. Will start a separate topic with progress I make on my MP3DP v4 modded for 3D Chameleon…

I’m just a glutton for punishment LOL

I did come across this new build series and hope it comes out faster than I can build it LOL. I cant handle the live stream builds. Just too drawn out for me and too hard to move around to find the part you need

Good catch. The v1 for $135 9 color is the original vs the v2. That little detail would have enraged me for sure…

@Jonathjon thanks for trailbreaking that one for us.

The Siboor kit with 8 colors looks like it would work, but if I bought one I’d print it on a properly tuned v5 and so that is another year out, which pushes me to the Chameleon from a time standpoint.

@azab2c I think I’ll watch your build with interest before I pony up for one.

I have been considering adding multi-material capability to a printer for a while. I may actually put some effort into it this summer.

- The ERCF seems like a fantastic project, and the availability of hardware kits is a big plus, but wowsers what a complex build!

- The SMuFF v3 looks a bit simpler (though still not trivial), but lack of a hardware kit means sourcing complexity.

- 3D Chameleon is attractive and probably the way I’m leaning for a currently supported option, but the price is high enough and my confidence that I can get it installed and working well is low enough that I am currently paralyzed.

However, considering that even having even just 2 materials (colors) available would be a huge upgrade and looking at the Happy Hare firmware for the ERCF, it feels like I should be able to utilize simple bowden extruders in a “Type-B” or “Type-C” arrangement without too much cost or complexity.

In fact, I think it is plausible to gang two or more drive gears on one shaft (common filament drive stepper) and just have one “servo” for each to engage/disengage the material tensioners. This isn’t described directly in the configuration types, but seems likely already possible through the configuration options - or at least it would be a relatively meager pull request.

I probably have enough hardware & electronics on-hand to give it proof of concept whirl with no out-of-pocket expense, but would struggle to create a configuration file for any controller I have on hand by myself. So, I might order a BTT MMB (recommended ERCF control board) to kick things off unless someone sees an obvious flaw I’ve missed; worst case, I could fall-back and print some ERCF parts and see how bad the assembly really is ![]()

Fystec also has an RP2040 based ERB board with 2 integrated drivers for less, but the BTT version appears to have a lot more flexibility and would be easier for me to get.

Mechanically, the biggest challenge I currently imagine is a tension/release mechanism design that works with modest torque servos (hopefully ones I have on hand).

BTW, the MMB looks like it could also be a viable zen-xy controller with a klipper setup, so maybe that is my fall-back project if my home-brew MMU concept fails…

I stumbled on this one a few days ago, not sure if it is officially out of beta yet but looks pretty slick. GitHub - Annex-Engineering/TradRack: A MMU system developed by ANNEX Engineering, All those others ones are catching my eye as well. I would love to have one printer with at least one other color if not 3-4. I can not imagine ever needing more than that.

That, good sir, is “Brilliant” and maybe simple!!! Love it.

I’m still chugging along with my ERCF build. Have hit a few self induced snags but slowly making way. I need to update the build thread LOL

For what its’ worth, SMuFF is up to v6:

There’s a lot to like about ANNEX Trad Rack.

- The 2020 / MGN frame looks simple and rigid.

- The moving feeder motor means only one complex part.

I don’t think I have an MGN rail laying around, but I do have 2020.

I might start printing the parts for this and see how they look / fit.

It’ll at least give me a starting point for the tension / torque need to engage the feeder drive and servo requirements.

Upon closer look at the SMuFF v6 documentation, it looks like they have instructions / configs for skr control boards. Getting by without committing to a new control board might not be as bad as I originally thought.

And they support Klipper.

All of the spool management “solutions” are a whole other bag of complexity, but that largely stems from unloading the entire section from the hot end to the filament selector.

It you only run 2 materials you could put the splitter at the extruder and limit the unloading length to 50mm or so. This would require two tubes running to print head, but I think that would be okay. If you add a bunch more it might become problematic quickly.

A filament cutter is also a highly encouraged “option”.

Done right, that and a filament detector could be built into the splitter. However, I’d be tempted to start without either of these to see how necessary they really are.

I’ve been watching JJ’s ERCF V2 build thread. While it is super impressive it has only codified that I do not have the skill, time or patience to tackle an ERCF build myself.

So I did put a little effort into noodling on what a less sophisticated 2 material system could look like.

Instead of polluting this thread further I will start a new one in hardware development - this is just here as a heads up and a thank you for the provocative ideas in prior posts.

I truly hate that my thread is pushing you away from trying to build one. You are the second person today to tell me that. I do everything the wrong way at least once or twice before I get it right and do whatever I should have done from the very beginning. That’s always been the case for me. One of these days I hope to learn from it but it doesn’t seem to be any time soon lol.

I really hope one of these other guys building one will make a build thread that’s not full of mistakes and aggravation. Mine is not the thread you should base building one off of.

I am sorry if my post read that way - I actually intended it to be a complement to you. I looked at the ERCF parts, BOM and build instructions and was quite frankly scared. It is a amazing project and you are showing it can be done, so if anything it is encouraging.

However, when I saw you go at it, it did show how even someone I admire could have trouble deciphering the nuances and options of the project in its current form. I still wouldn’t know where to start and feel like there has to be a way to “start small” in a multi-material venture. I’m sure you will ultimately be successful and hopefully blaze enough of a trail that someone like me could do an ERCF build, but as much as I like tinkering, building and learning, all of the options and accessories are too much for me ATM (ERCF, ERCT, ERF, ERPS, etc and versions / mods of each).

I am envisioning a 2-material machine that may have a higher per material cost, but since it is limited to 2 would still present a lower cost starting point. Also, by using off-the shelf cold-end feeders the build complexity could be a lot simpler.

I very much appreciate the chronology of things you learned along the way. Too many build documentations edit all that stuff out to imply a level of unrealistic competence. So, you have not turned me away - my assessment of my skills have driven me to seek other options.

I do my best to be open an honest. My build threads are basically “mess it up enough that eventually you luck up and get it right” lol. And I hope that someone can learn from my hard headed mistakes and not make them their selves