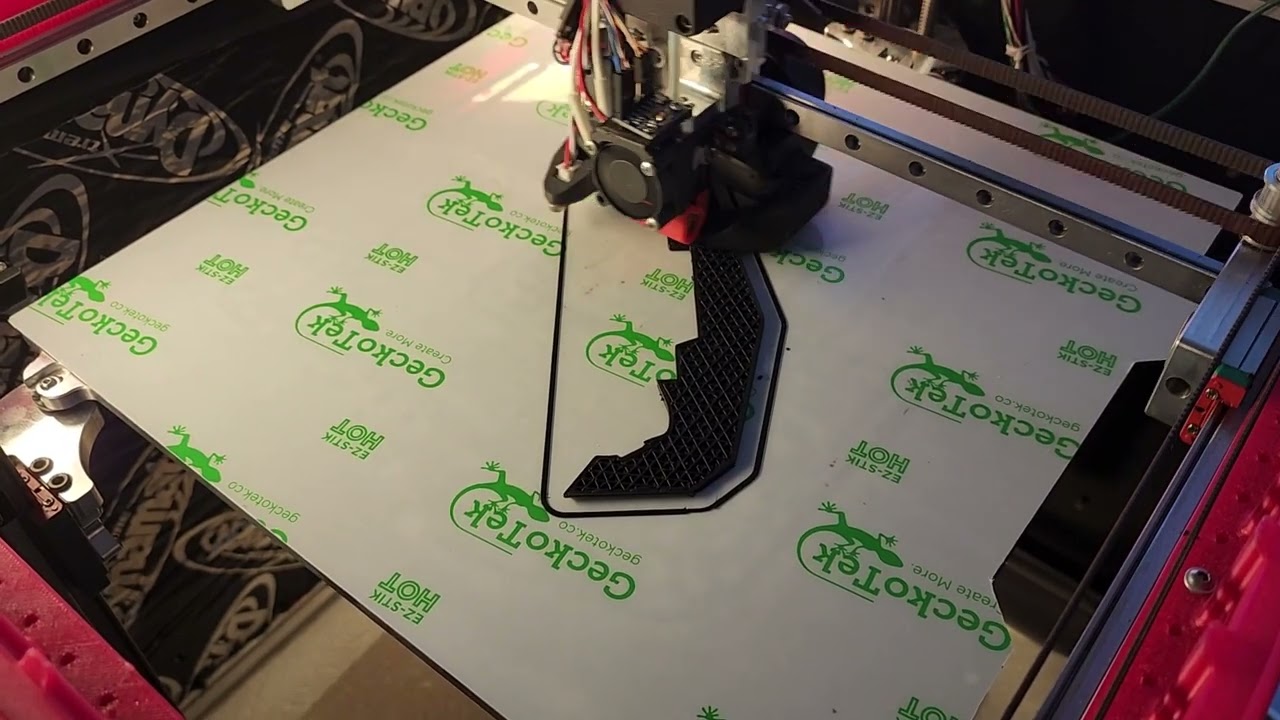

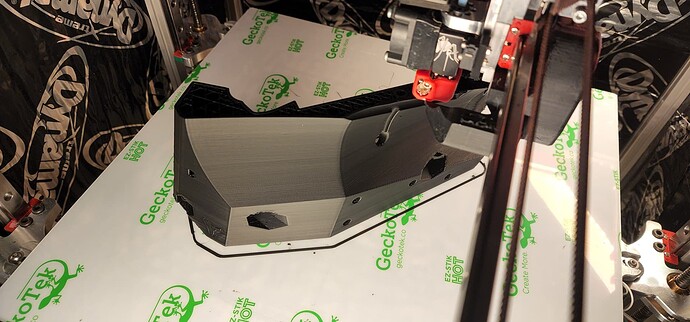

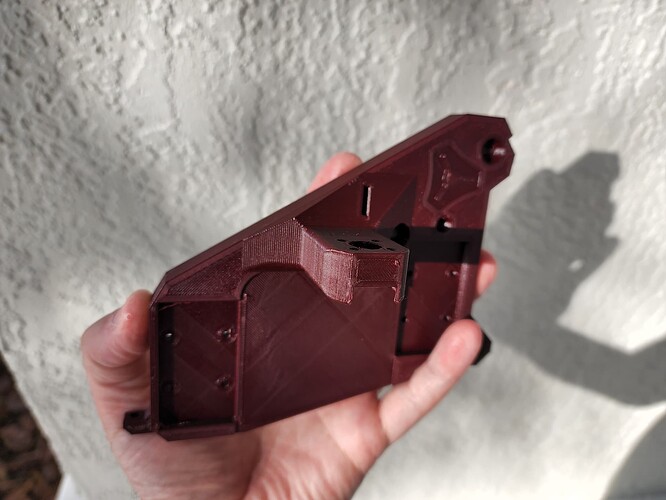

Using a .5mm nozzle at .4mm layers, 60% adaptive cubic infill at 100mm/s.

I knew you would print it!!!

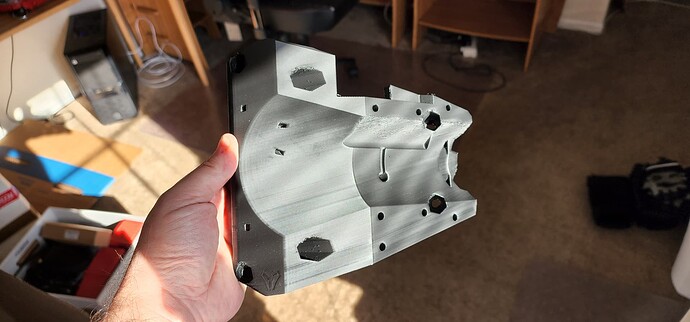

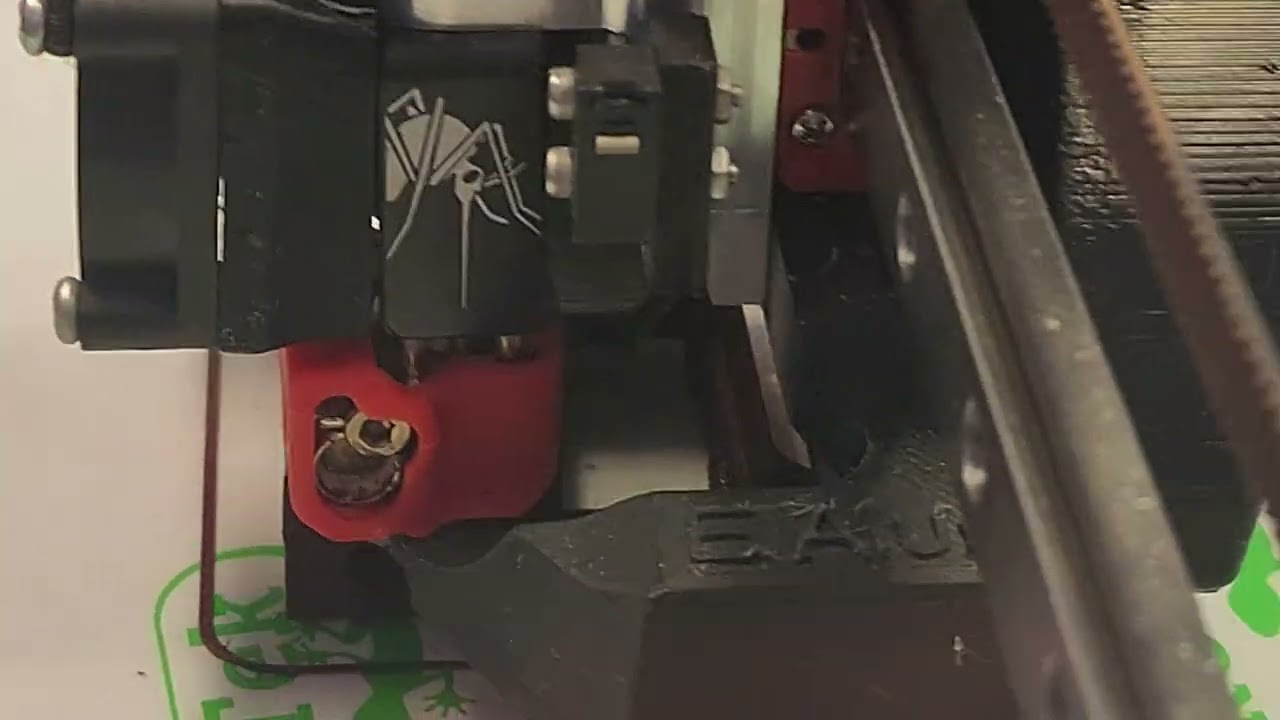

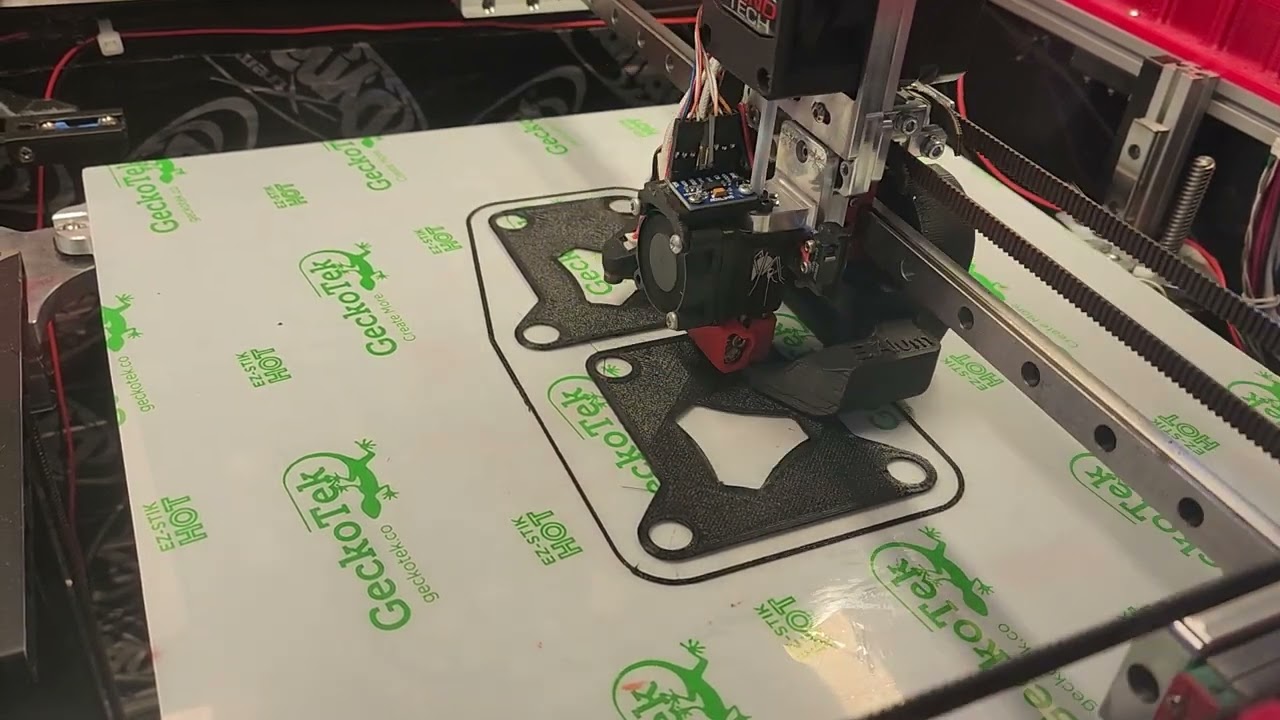

I was worried about that core. It is a pretty brutal test. I do think it can be done though. Your sags are exact highlights of what I worry about. Do you have cooling issues on other parts, as in not my parts, or just the core?

Cooling in general when I print this fast. The ducts don’t stay over the hot spot long enough. Also found I didn’t have any retraction settings. I never set them back up when I switched my printer over to Klipper. We also don’t have the AC running right now and it was about 80 in my office last night.

Sweet, I was getting nervous. As long as that is kinda expected, we are safe.

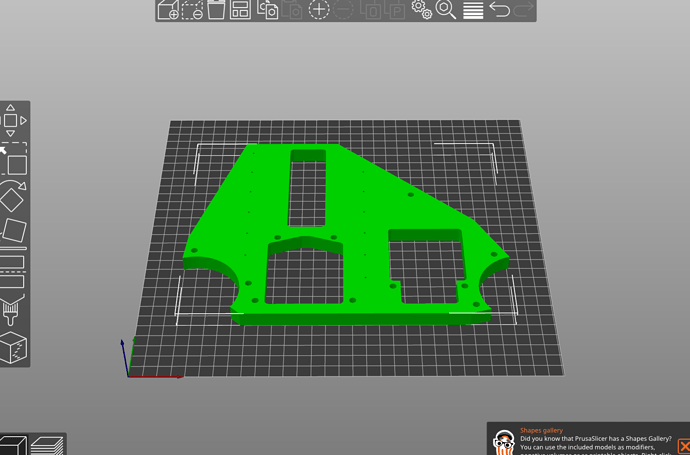

These parts are definitely “harder” to print than any of my previous ones. Larger overhangs and steeper angles.

I think printed is an option for those. That will be nice for people with larger beds. Might have to make a bigger one just so I can offer them printed as well.

Yeah. That looks great. If nice to have red that isn’t super bright sometimes. I bet it looks better in person too, because of the reflections.

Dang that is nuts

A post was merged into an existing topic: LowRider 3 CNC, LR3 Release notes

Time to get that new place dirty!!!

Hopefully the box grid will be straight enough. Don’t have a table saw, so I’m stuck using a circ saw and a guide.

It will end up flatter than mine for sure!