VFAs (Vertical Fine Artifacts)

Ellis’ Print Tuning Guide

I had it at 200 also.

What about lowering your extruder pinch pressure.

Maybe you are pinching it so hard it is making big groves and they are making pressure waves?

So, when I got my first V2S, it was making a terrible noise. I realized at some point that the gears were super tight from the factory so I loosened it a little.

Since switching, I haven’t adjusted it, however, I’ll admit that I have no idea what I’m supposed to be looking for for it to be the “right” amount of tension lol.

I’ll look into it and if there’s some recommended way to calibrate then I’ll do that

Its never that easy. The lowest tension before it slips. There is a huge range.

well…I don’t really know what a reasonable extrusion rate is…

But it’s not a very big range of adjustment before the 25mm at 25mm/s slips…like 1/4 turn.

still a ripple.

But it did it also on JJ’s Orbiter, and Rob’s printer, etc. so I’m not sure what the likelihood is, unless all of ours extruders aren’t adjusted correctly.

The engineer in me is really annoyed that I can’t figure this out, and strives to know the exact reason it’s happening…

The user in me just wants it to go away and doesn’t really care if I ever know what it is…

It’s a struggle…

I am increasingly suspicious of a Klipper artifact/bug. For example, if the gcode segments were subdivided into smaller movements and those movements were subject to “rounding errors” (or something like that) either in position or in timing.

Previously you had observed little or no difference as a function of speed, and now it’s a roughly 2x difference with a 2x difference in speed.

Maybe the “rounding errors” (for lack of a better term) are not linear and depend on how Klipper decides how to subdivide the movements.

Perhaps print the box again with incremental differences in speed, say each 5mm in Z goes 5% faster. Maybe the period (in mm) is constant until a certain speed and then the period jumps to a different length. That would be a smoking gun for a Klipper bug. Or maybe the period increases with each increase in speed, in which case it would be interesting to see if they are in phase at the corner or if they are randomly out of phase from each zone to the next. If they are in phase at the corner then that would also strongly suggest a Klipper artifact and not a mechanical issue. Maybe there is one frequency in input shaping that is not decaying to zero like it should.

That is a great idea.

So are you thinking more in terms of an XY motion bug, or an Extrusion sync thing? I pretty much rule out Z. I feel like extrusion being out of sync with motion feels logical.

If I could just figure out when mine does it I could be more useful. I do always have a texture on XY but my diagonals are pretty good. So I have no idea if mine is just different now or a set of cruddy bearings.

Previously you had observed little or no difference as a function of speed, and now it’s a roughly 2x difference with a 2x difference in speed.

Well, I saw a smaller pattern on one print. That print happened to be at a slower speed. I have not looked closely at all the differences or definitely correlated that a change in speed definitely changes the pattern as an absolute.

I was randomly researching potential printer replacement options and came across some people discussing having issues with ‘VFAs’. I’d never heard the term before so googled it to find that it’s ‘Vertical Fine Artifacts’ and a page had a picture that looks to me to be pretty similar to the issue you’re having.

Ellis’ Print Tuning Guide

No idea if that’s something that’s already well known and I’m only just seeing it for the first time but I figure it’s worth bringing it up just in case it’s different groups of people trying to solve the same problem but using different nomenclature for the issue.

The tuning guide above seems to mention a lot of the same potential causes and solutions that have been mentioned above (belt tightness, belt quality, idler/pulleys out of round, bearing issues etc.) so I don’t know that it’s directly helpful, but I can’t see any mention of calling it a VFA so maybe that’s another avenue to chase it via?

Edit: Another interesting reference: Technical Details

This page is ascribing it to motor resonance rippling, which I think was one of the theories called out above? It has a bunch of explanations about their take on it that seem to me to match some of the variables seen above. It seems to be dealing with an i3 style printer and I don’t know enough about the more modern klipper + self tuning approach to know if that should be able to solve it. The claim that it occurs in most printers including older industrial printers is an interesting one. Some of this would make sense for the issue being so variable amongst different printers, potentially even different amongst the same design but with different components. A relatively benign change in stepper motors with the same specs but different internal designs could result in a significantly different resonant range for the whole assembly, as could bearings/linear rails/belts etc.

Again, no idea if that’s helpful, just a random thing I found and thought was interesting.

So orca slicer has a vfa test print. Prints like garbage for me, my normal prints are nearly flawless. So I think made a good connection there. I think the two terms are getting interchanged. Vfa’s to me are a bit different more of a pattern instead or ripples but now that you mentioned it. I bet there is a ton of overlap.

I’d never heard the term before so googled it to find that it’s ‘Vertical Fine Artifacts’ and a page had a picture that looks to me to be pretty similar to the issue you’re having.

I’ve heard the term, but I prefer “The Ripple”

It’s a lot more ominous and scary lol

Since my previous comment, I’ve seen maybe more than 100 references to it on the posts I’ve been looking at on the Creality subreddit. A quick search on the Creality, Prusa and 3DPrinting subreddits shows a lot of posts discussing it. A marketing highlight for the upcoming K2 Plus even mentions VFA reduction due to new pulleys, idlers and motors.

So assuming that it may be the same underlying problem, that’s a lot of printers out in the wild that seem have it and not just CoreXY platforms. Given the previous resource discussing it in terms of motor/motion system resonance and that being excited by torque ripple due to belt/pulley pitch, it doesn’t surprise me that it seems to be a common and ‘whack-a-mole’ type problem. Fundamentally, every 3D printer I’ve since the Darwin has used steppers and belts so it’s potentially a problem as old as 3D printing itself.

3D printer I’ve since the Darwin has used steppers and belts so it’s potentially a problem as old as 3D printing itself.

Come to think of it, the old Lulzbot AO10X the local makerspace had a farm of had this behavior - significant VFA. Although in that case I’d call it VCA (Vertical COARSE Artifacts.). Those were basically just fancy Mendel 90 printers.

Interesting.

I guess regardless of how good the term is or whatever anyone’s preferred nomenclature is, it does seem to be extremely common so I’m just bringing it up as a way to connect the troubleshooting here with the wider world. It could also allay some of the concerns raised such as Ryan seemingly worrying if it’s an issue with the V5, some of the other comments about it being coreXY related etc.

The one thing that I can say is I never saw it on my old printers, but my old printers belts have never been ever remotely this tight. I might loosen one up and see how my artifacts look.

Building that first V5 and following the klipper belt tuning had me pretty freaked out. I will gladly give up 5-10mm/s if I had to, to get rid of this new surface texture. An experiment that is worth a shot for me.

I ran the VFA test print last night before bed from 40-200mm/s, but didn’t have time to really take a good look at it.

At first glance, it looked like the ripple showed roughly between 60-150mm/s for me.

I played with the belt tensions a little at one point, and going tighter seemed to make it better for me, but I never tried going looser.

Ryan I noticed on my v5 after doing all that my belts were relatively loose. And still was in the 90s on the belt graph. You might be on to something. All those ones for the belts are for 6mm belt. We run bigger belt and don’t need it as tight

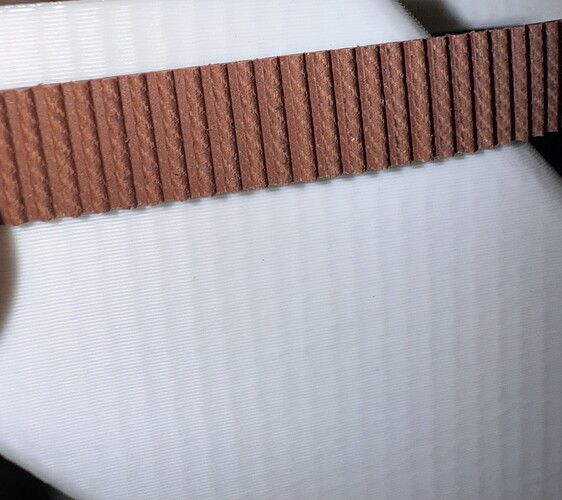

How are your ripples gents? Noticed 5mm frequency on mine too, to me, seems to be periodic bulging causing width variance of 1-2% between cycles. Also using Biqu V2 H2S Revo.

Close up…

I think that is far too big to be ripple. All the ripple I see is vertical on flat walls and about 2mm apart. That looks to be wonky extruder gears or maybe a lopsided idler or pulley?