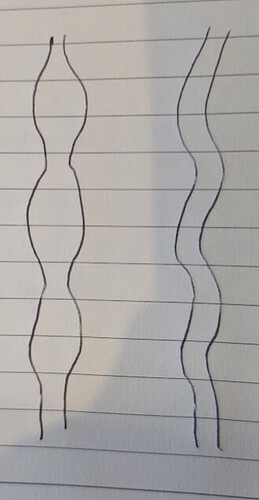

If it was flow related you would expect that the ripple would be symmetrical on a single wall print (bulge on both sides). If it was backlash or some physical concentric movement the inner and outer surfaces would be parallel. If you print a single wall, does the ‘inside’ and outside look the same?

Does this picture help what I’m getting at? Flow related ‘bulging’ on the left.

So, I did look at this I’m pretty sure, and I “think” that it’s a bulge like the left.

This is why earlier in the thread somewhere I think we discussed about thinking it might be some vibration causing vertical movements, which maybe could explain why it gets better when the layer height gets bigger, because it has more room and is more forgiving…

Or maybe I had that conversation off to the side…

Or maybe with myself…

ahh yes… at least one of the conversations about it was in here ![]()

@Michael_Melancon, I don’t have anything to contribute other than a virtual hug of encouragement ![]() .

.

Really appreciate your persistence and being bold enough to share your thought process, and progress throughout. Cheers!

Just to show how frustratingly in circles this goes…

When I got home I downloaded and installed Cura. Built a profile starting with a Voron 2.4 standard profile and tried to get it to match speeds, etc as best as I could.

I did the same thing I normally did in Prusa to add the box to the plate, then exported that box as an STL.

Sliced in Cura and printed…

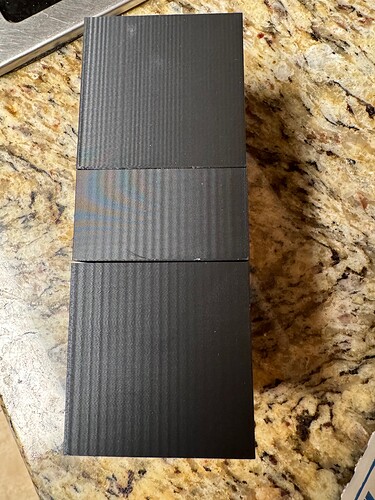

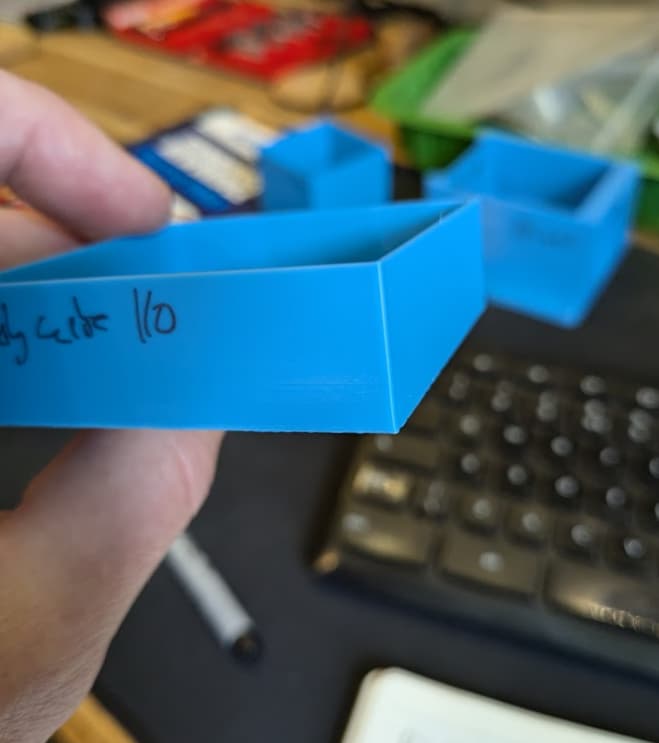

The Cura printed box is the one on the right. The ripple looks identical to what I was getting previously before I changed the nozzle

The box on the left is the one I printed from PrusaSlicer last night.

So previously, I thought the nozzle change caused the smaller pattern to show…

but now…

(manshrug)

I am printing another right now from PrusaSlicer at the same speed to see if I get the same pattern.

The I’ll come back, likely as confused as ever…

Acceleration.

This has to be acceleration.

In Cura, what are the accelerations set to?

acceleration control in Cura was disabled.

Printer currently set to 7k for both of those tests above that printed different.

Previous tests were at 5k before nozzle change.

Further up in the thread I also had tested dropping accels down as far as 500 with speed at 40mm/s and it was still there….

Hmm. That should mean you get whatever the defaults in Klipper are.

Since you had single wall prints with lines on both sides, the acceleration/motion that seems to drive it is steps through the extruder. But I’m not sure how the two different slicers would give different results for the same flow rate.

Did you set a volumetric flow limit in Cura, or is it just using stepper speeds for the extruder?

Crazy that slicer makes this much difference.

There was no flow limit.

I had forced it to 110mm/s speed to match my previous tests.

The one with the small lines ran at a slower speed near 80mm/s.

Previously this did not change the pattern, but it seemed to last night for some reason

It’s a 2 wall print.

I had done some single wall ones previously too but I don’t think it changed anything

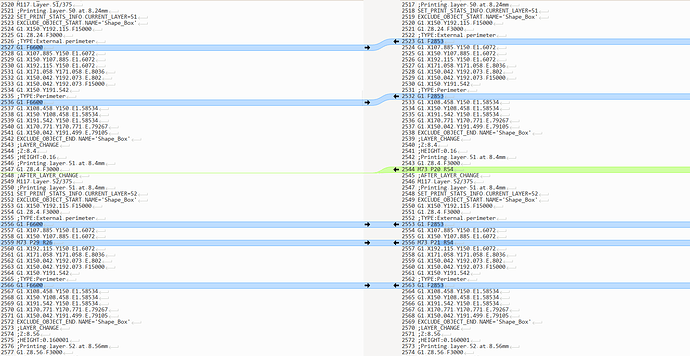

Gcode of the two for comparison?

Ok. Prusa slicer print today looks the same as the Cura one, which matches all the previous results….

So the last night one is the mystery I guess…

Last night Prusa

Cura

Prusa just now

Prusa Just now (110 mm/s)

gcodes-2024619-221049.zip (43.5 KB)

Cura (110 mm/s)

gcodes-2024619-221129.zip (42.1 KB)

Prusa yesterday (slower print, previously didn’t change pattern with 0.6 nozzle)

gcodes-2024619-221156.zip (43.7 KB)

nearly 2x the speed, nearly 2x the ripple spacing?

Is anyone on similar enough hardware to try printing these exact files? I know you have been there before, but it feels that so much has been tried that its almost worth starting again with a much simpler set of parameters and recording changes. Depends how much more work you want to put in. I’ve not really got anything to suggest or any expertise!

I was thinking that klipper does all sorts of stuff beyond what is contained in the gcode, perhaps post your current klipper config that was in place when this gcode was printed?

Edit, It prints on my modified ender 3 bed slinger running Klipper. I’ll post results in a few mins.

So I printed your gcode - and - there is a ripple. I don’t think I have ever noticed that before. Its hard to photograph and I can’t feel it. You gave my printer the ripple virus ![]()

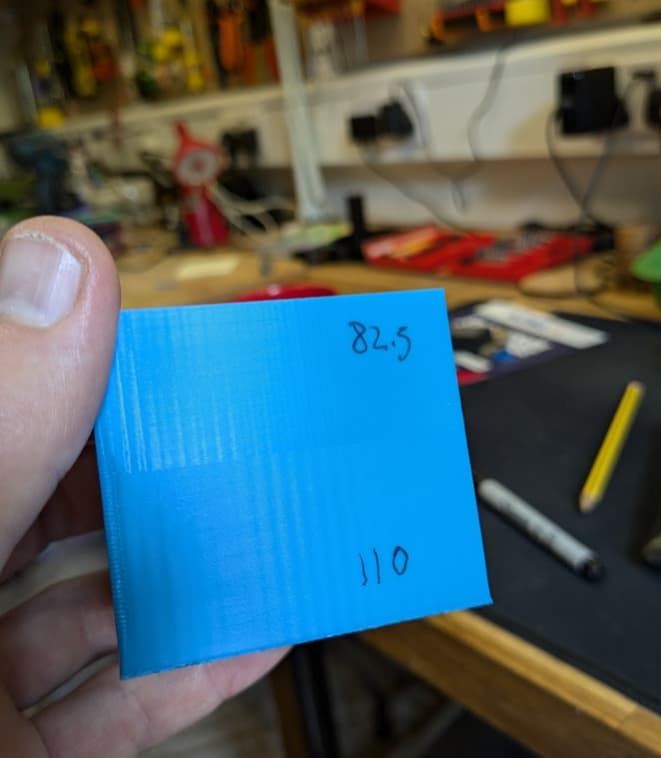

At about layer 180 I slowed the feed by 75% (in klipper) to bring it to my usual ~82.5mm/s printing speed - a subtle change in the ripple but still there.

So I just used prusa slicer to follow your method as I think it is: Place square; make 60mm; turn 45 deg. I changed my print speed to 110mm/s and 2 walls (also changed external wall speed to 100% from 60%). Other than that I kept my usual settings - I’ve not dug deeply into the settings at the moment -but I wonder if you could try printing this cube that I created?

rob box 110.zip (39.6 KB)

It prints on my machine without a ripple.

If my cube prints on your machine without a ripple, perhaps we can dig further into slicer settings?

Starting the print now.

3 things I notice are a little different.

My file was at 0.16 layer height, yours is at 0.2

My is extrusion width is 0.44, yours is 0.45

My temperature was at 220, yours is at 200.

if I don’t see the ripple in the first portion, I will up the temperature in steps to test that one as it’s going.

The layer height one might be important though because we saw before that larger layer heights made it less pronounced.

Will report back when it’s done.

Hi

I’ll slice again to those parameters and see too. So many variables.

It’s still printing, but the ripple is there for me.

It is a little more faint, but I can’t say for sure if that’s a layer height thing, or if the slightly wider wall helps