I’m starting this thread because, well, to be honest, I’m at my wit’s end with this one…and I hope someone here has seen something like this before and can maybe point me in the right direction.

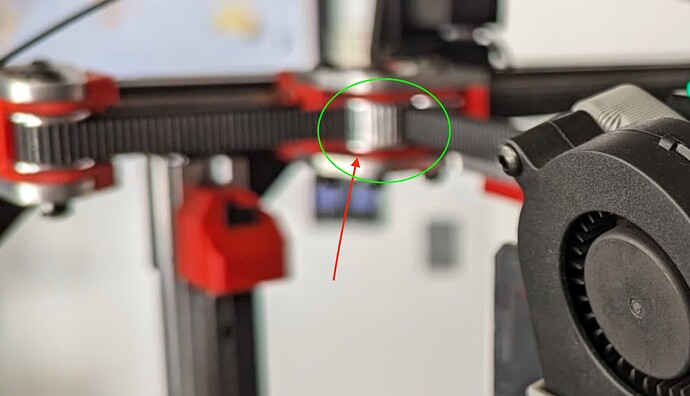

Since finishing my MP3DP v5 build, I have been chasing my tail on an issue, and I have taken apart my XY motion system multiple times already trying to figure it out.

For reference, there are 4 of these machines currently alive, and mine seems to be the only one with this issue.

Here’s the issue when I print:

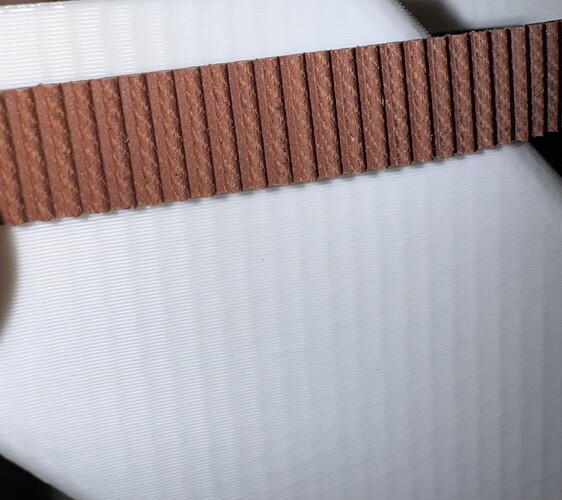

This vertical wave pattern appears

This was printed at a 45º angle. The pattern only appears on the side that engages the B belt path. The A belt path doesn’t have the same artifacts.

What I have tried

- Disassemble and clean the rails. they are very smooth when the belt is off.

- replaced the belt

- replaced some idlers that looked like maybe could have an issue.

- printed an alignment block for the motor mounts to ensure that the top and bottom plates are aligned properly

- tightened down all screws ( these came loose on me once when they weren’t tightened all the way)

- ensure the belt has enough tension on it.

I’ve been back and forth between thinking I had it solved, and then not, over and over for the last few weeks.

When I loosen the belts some, it gets worse. My belts are currently probably slightly over-tightened just lessen the effect some.

When I print with larger layer heights, the it gets better…

For this picture, the top large print is at 0.2 layer height, and the bottom section is at 0.3 layer height.

This is all being printed at 110mm/s and 4k accels.

Input shaper tuned using the tuning tower.(Klippain-shaketune does not produce good results for me)

I have tons of other details, some of which may be important, that I might be forgetting, but just ask and I can provide any other information that might be important…

I don’t remember ever coming across this online with anyone else’s printer, so I have no more ideas at the moment, short of replacing all of the pulleys just in case? Pulleys were all originally bought from Ryan

I have not tried a different extruder.

I wonder whether some vibration somewhere might be causing it, and maybe the smaller layer heights just aren’t able to hide it as well? But the fact that it is such a consistent pattern…I don’t know.

Hopefully someone out there has seen something like this before and maybe has a clue.