Okay, first off…

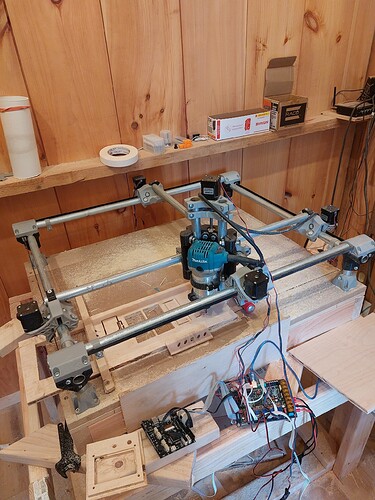

Make sure the belts are reasonably tight and that there is no wiggle in the machine core.

Check your CAM. The bit size could be wrong.

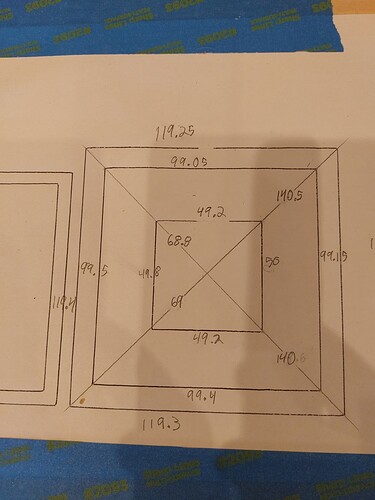

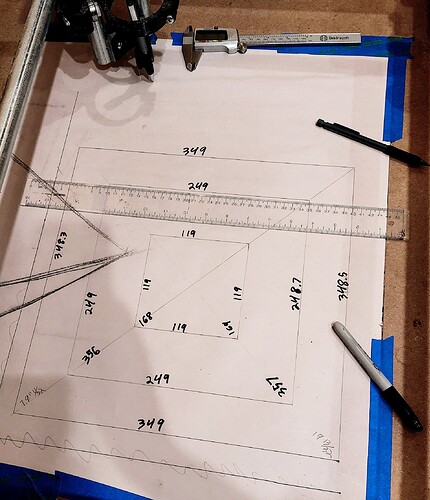

My first few parts were off, holes were too small, parts were too big. So things that should have fit together did not.

Cut some parts in foam, or something soft and cheap.

Cut some rectangles (with rounded corners) and holes, and try to fit them together. Try these in 2 different sizes, say 50mm and 100mm.

If you have your cutting diameter too small, the parts will be undersized, and the holes will be oversized, and you will have a sloppy fit.

If you have your cutting diameter too large, the parts will be oversized, and the holes will be undersized, and they won’t fit at all.

Adjust the cutting diameter until you get things to fit tightly, but actually fit.

Now that you have a cutting diameter that matches, measure the size of your parts (and slots) and compare them. Because bow both are the same size, any error between the parts and the CAD is the machine movent.

Label the parts for X and Y axes, so you know which size is off by how much.

When I was done, I found that the 100 steps/mm was right.