I did about a different issue. I didn’t bother with that one because I was at the end of my return window and didn’t have time to see if they would do anything about it.

I never take my filament out, unless I’m changing color or changing what kind of it is or I’ve run out at the end of a roll and needing to put a new one in.

I think every now and then (perhaps, regardless of brand) a roll of filament will have a little bit of grit or sand or stone or something in it that creates a problem. At least that’s my theory. I’ve had pretty good luck with pressing filament through it and getting a partial clog cleared out. I’m still on my original stock nozzle on all three of mine, after lots and lots and lots of printing. I have occasionally had some partial clogs that I got cleared out.

Any tips for me to try to unclog mine? I watched a YouTube video where a guy used a 0.3mm Acupuncture needle to unclog his. I ordered some from Amazon. They’ll be here tomorrow.

I’ve heated it up more that the called-for temp, like 240 or more instead of 220, and then while extruding, used finger-pinch pressure downward on the incoming filament to increase throughput.

Also, I’ve alternated the above with unloading and / or “cooler” pulls, on the chance I could perhaps get a chunk of foreign material pulled out through the top.

Try to use your printer from a filament dryer connected, the clog issues have happened to me also: i did solve them using the thinnest needle from my old ender 3 kit followed by a couple of purges each time. ( Re-dried that roll of filament and never had issues again, for pla i used 220° set ) The glue they shipped with the printer works beautiful to prevent lifting

Thanks Doug. I’ll give those a try.

Thank you Cesar. I hope the needle I ordered works for me too.

Hi Britt, sorry for your misadventure.

I have also had the Flashforge AD5M pro for about 3 months.

I have printed many objects (about 4 PLA spools, of various brands) without problems.

I have never changed the nozzle, I print at the temperature indicated on the spools (usually 210 C) and heat the bed to 60°

If by chance at the beginning of the print I notice a bad adhesion, I stop the print and redo the automatic leveling before postponing the print.

I have often replaced the spools to change the color, without any problem.

I hope my procedure can help you too.

Thank you Paolo. I hope I can figure out what caused the problem. I will keep your suggestions in mind.

I have my 5M. I’m going to install the Klipper Mod, so question, at what point should I install it? I don’t know if its install changes or resets anything and I would have to set right back up, therefore wasting time, plus I’ll be printing PETG to start for awhile, so didn’t want to stick PLA through there if I have to as I heard changing filaments might cause a clog.

I think it’s helpful to think of the stock UI and the Klipper Mod as two different walled gardens. What you do in one does not impact the other. Any calibrations or bed mesh or vibration tests done in one, does not benefit the other.

I’ve not heard of any clogs caused by change of filament type (such as from PLA to PETG). I have changed filament types from PLA to TPU, from PLA to PETG, etc, and never had a clog. I think clogs are most likely caused by tiny impurities in a filament strand that somehow made it through quality control efforts, such as bits of grit, metal, sand, etc.

Okay, sounds good, so far far should I take the stock software setup before installing the Klipper Mod? Thanks.

After installing the Klipper Mod, then at any time you like, you can click a button that boots back into the stock firmware. So knowing that’s a fallback, I would suggest having the stock system calibrated and usable. I’d not go for installing the Klipper Mod until the stock system is ready and usable.

I want to thank you guys again for your help and suggestions for things to try. I increased the temp to 240C and purged the printer several times. I also did several cold pulls. My 0.3mm needles showed up yesterday afternoon and I used them on the nozzle. I started a print and part way through the filament quit feeding. I was hearing a clicking sound when it happened.

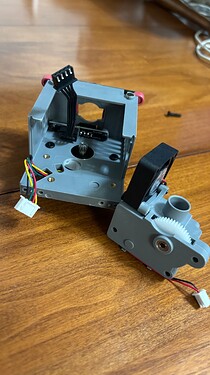

The FlashForge tech support had sent me a link to a video to take the extruder apart to check the feeder gears. I didn’t want to do it, but I ended up taking it apart to check the gears. Thankfully the gears weren’t damaged. I ran the cleaning rod back and forth several times through the feeder.

I reassembled the extruder and put it back on the printer. I printed the test cube and it came out great. So I printed a bookmark and 2 more stop blocks. Then I printed a fidget spinner for my grandson. They came out great also. Now I’m back to printing the replacement parts for my MPCNC.

So sorry you had an issue, but so glad you got it resolved! Great looking prints!

This is a real thing. PLA and PETG are not compatible materials. I swap nozzles when I change materials. If you don’t do this, you’ll eventually have problems.

This is also real. I haven’t fixed an A5 nozzle yet with this problem, but I fix it oscassionally on the FFCPs and TAZ printers.

Can it just be calibrated the first time with PETG then?