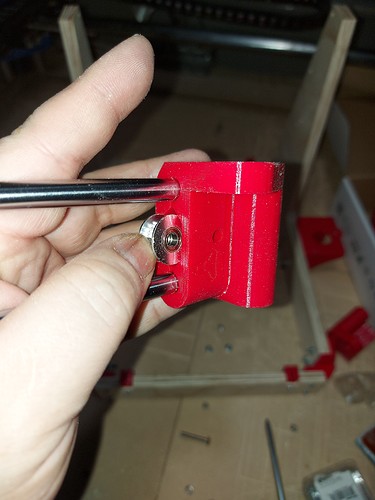

I’ve been messing with the firmware, to see if I can implement dual endstop homing. I think I’ve got it sussed, now the problem is going to be setting up the physical endstops.

Ryan’s parts are of course configured for the NC switches. I’m going to have to retrofit something. It would be nice to be able to mirror the left side mounts, but there are a couple of reasons why that isn’t a good plan, not the least of which is getting a wiring solution to the right side X end.

So the idea will be to add flags to the X ends, and mount optical stops to the Z motor mounts. The trick will be the adjustability. Since this is going to determine the Z=0 height, and it needs to be precise, there has to be some fine adjustability available. I may end up stuck with the kind of solution that I usually dislike.

“I have some of these unusual and sometimes very difficult-to-get parts, so I’ll use them.”

I dislike it as a solution, because it’s not something that just anyone can use.

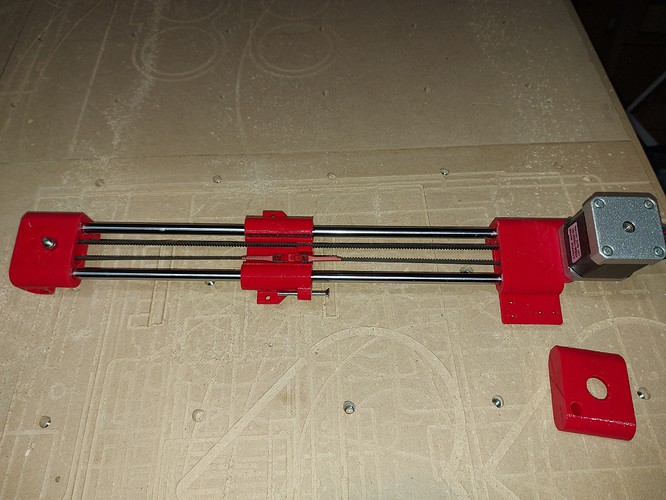

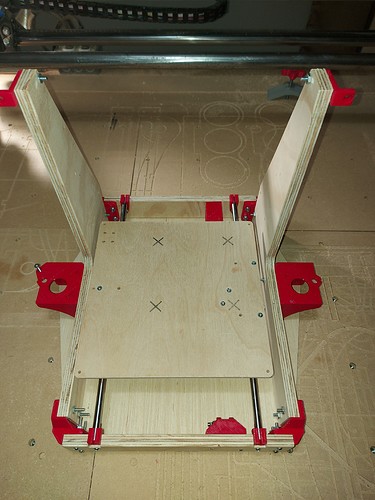

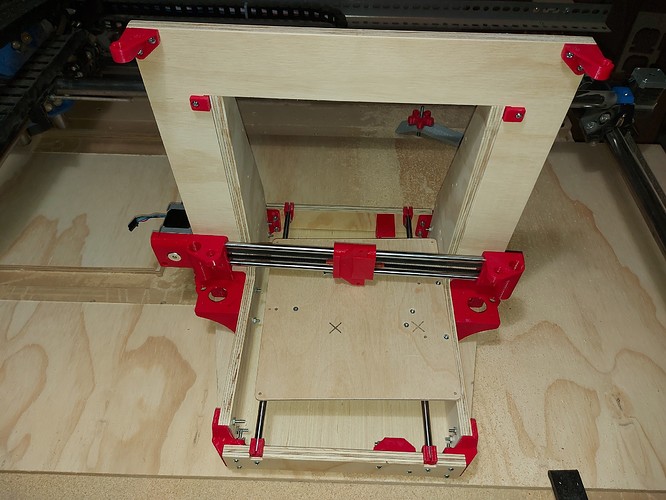

Anyhow, this is the current state of things. I took the bottom off to install the Y motor and belt. There are a couple of spacers in the Y bearing clamps to keep the rods centered for testing, and so I can figure out the placement of drag chains for the heat bed. So tired of things snagging a wire and unplugging something.

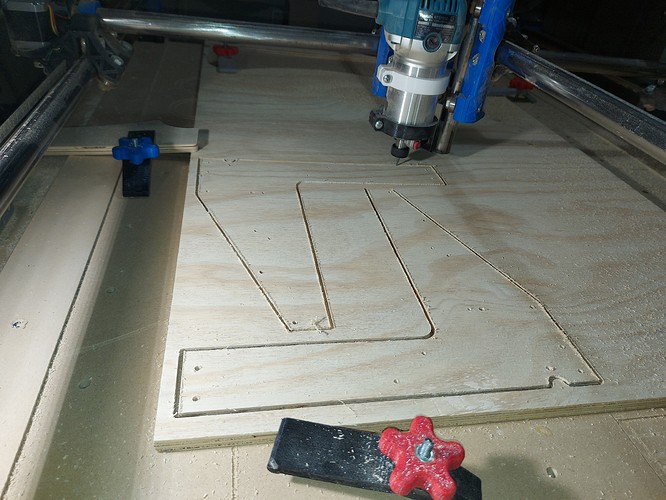

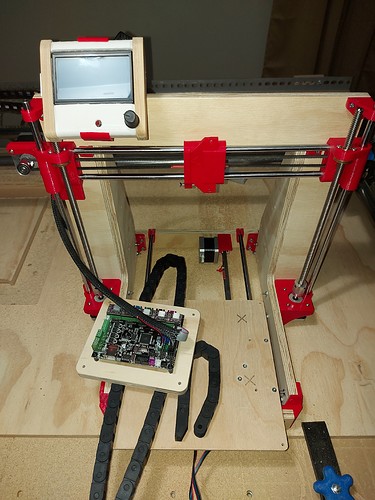

I re-mixed the LCD holder to clamp onto the XZ frame, and milled a baseboard for the MKS Gen L v1.0 board. It has a 1/8" pocket under the board, so I could just screw it directly down with #6 PC case screws, which will make things easy. I did a printed case cover in CAD, but want to see what I need as far as cable accommodation before I actually print it, particularly since I don’t know what I’m doing about the Z endstops.

I did have an idea, put optical stops in at the top to level the Z motors, and use a probe to find Z=0, but I have no idea how to do that with Marlin. I could do it with RRF on the Duet easily enough, and now that I’ve thought of it, I might on my current printer.

Looks like I need a few more pieces, something for a power cord plug in, and I think I’m going to go with a Bowden style extruder after all, so I need pieces to mount an E3D V6 Jhead to the carriage.

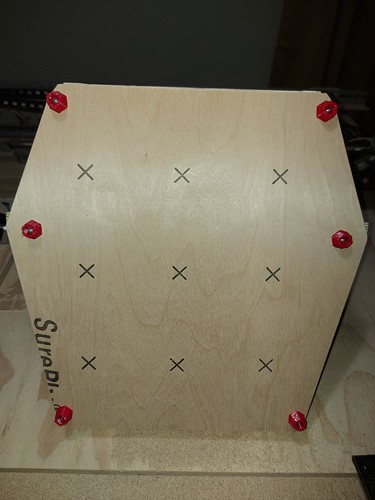

My spool of filament arrived, and I messed up. It’s a transparent red, so it won’t match right. Looks really cool though. I can either live with a mismatch, or just plan to replace anything I print for it in the next few days.

I noticed something a little weird. The Y platform does not sit centered in the frame. It is about 1/8" closer to the left frame than the right. I don’t think this will cause problems though. I believe the bearing holders are centered between the mounting holes, and the belt holder is perfectly in line with the idler and pulley. I just thought it was a little weird.