Well two months later…

Since my last post here I have finished working on the cars, and managed to get a bit of progress on my LR3 build:

- Designed and built a tilt-away/roll-away table base.

It makes a huge difference in being able to move the LR3 out of the way so that I can get the cars in the garage when needed. Link to the thread is here.

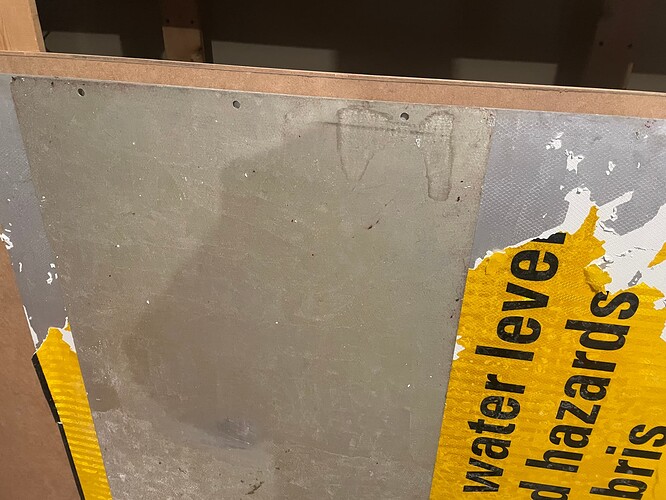

- Installed the hardboard struts that I cut back on Jan 07 (post #105 in this thread)

The hardboard has a LOT of flex, so my plan is to cut out some blank struts from 3mm aluminum sheet (salvaged signs) and place them behind the hardboard struts. I also want to paint the struts (probably black on the aluminum and red on the hardboard, to provide a contrast for the lettering), but that can wait for now.

I also put some epoxy on all of the non-captured nuts, so that adding the aluminum backing hopefully won’t be too much of a PITA.

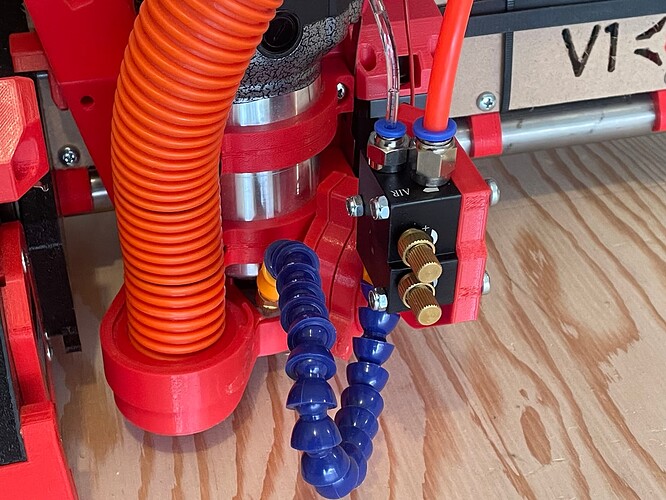

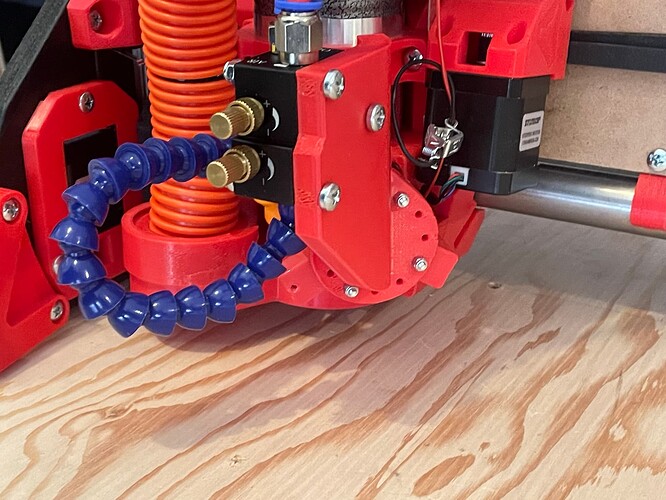

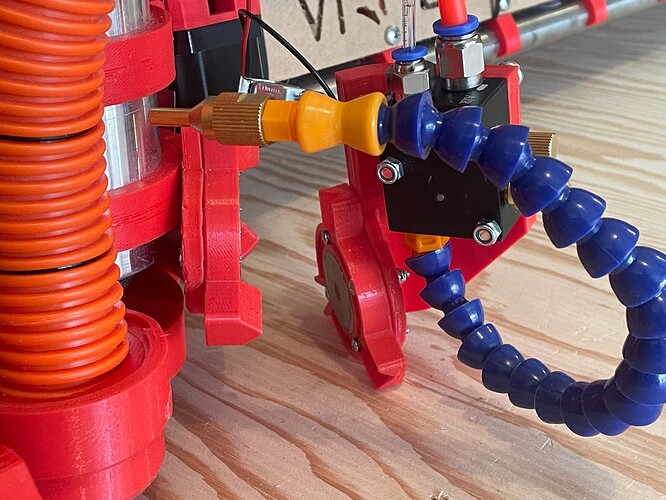

- Installed an Air Mist system for cutting aluminum

I used @DougJoseph’s kinematic tool holder (modified with @jamiek’'s “mountains and valleys” fixed and mobile parts), and Doug’s Air Mist Attachment (Side mount version model B). For more info you can check out this thread.

I still have a few bits and bobs to mount the air hose system to the table (valves, elbows, etc), and I had a couple of hiccups with printing the tool holder (post #200 in the tool holder thread), but overall it works great!

- Designed and printed a “quick release” system for my built in vacuum/dust collection hose.

I had a bit of an issue where the outside of the prints were very close to the design value, but the inside of the print (hole) was about 0.5mm too small. I used post-processing (sandpaper) to make it work, but it looks like I need to go into Cura and play around with the “Hole Horizontal Expansion”" settings.

Coming up - I bought some 9mm aluminum for the YZ plates, and I scrounged a bunch of 6mm aluminum for the XZ plates, and now that I have the air mist system up and running, I’m working on setting up the files in Estlcam to cut those items. I’ll probably do some test cuts with the 3mm aluminum for the strut backing first, but I need to finish removing the vinyl and adhesive from the old signs before I start that.

Whew, that seems like a lot of progress!