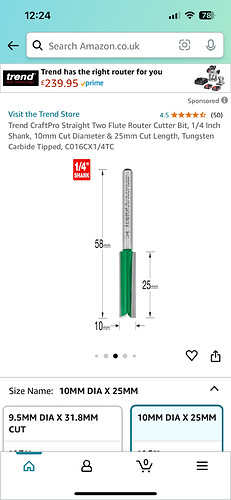

Struggling to find (easily available in the uk) 1/4inch router bits for the makita that are around 10mm thick. Any idea if this would be suitable? It’s from the lord and saviour Bezos

Why do you think you need a 10mm endmill? If you tell us the purpose we might tell you why something else might even be better suited. ![]()

Cutting 18mm osb sheets to create “Lego blocks” for building a cabin with.

The company that makes the files for the blocks recommends a 10-12mm bit

10mm needs a really rigid machine (or really slow and shallow cuts), the bigger the endmill the more material is going to be removed. I have been using 6mm endmills for 18-21mm OSB/MDF/Plywood and it works well, I don’t see a reason why anyone would use a 10mm (or recommend one). It really only makes sense if the size of the endmill is the limiting factor (which is never going to happen with a printed CNC). ![]()

P.S.: Do you happen to have a link? That sounds interesting.

That price seems ludicrously high. Ryan’s V1E.com store sells wonderful 1/4" carbide bits for $9.99 USD, and I know shipping and fees would be added, but, my goodness, 240 pounds for just one bit, sounds like highway robbery.

My advice is to completely ignore the 10-12mm recommendation. a 1/4" diameter cutting end will be more than fine.

Surely there has to be something available for less than that.

I think that’s an ad for the router kit.

the price is hidden below where the picture cuts off…

Whew! That makes more sense!

![]() Yeah thankfully they aren’t that expensive… Think those bits are about £12-15 a go. I’ll stick with a 1/4inch bit just now and hopefully that’s all good! Currently bootstrapping your table @DougJoseph. Cutting it first thing in the morning so I’ll do a full post on how it goes. Feels weird turning into a full time lurker to an actual user now

Yeah thankfully they aren’t that expensive… Think those bits are about £12-15 a go. I’ll stick with a 1/4inch bit just now and hopefully that’s all good! Currently bootstrapping your table @DougJoseph. Cutting it first thing in the morning so I’ll do a full post on how it goes. Feels weird turning into a full time lurker to an actual user now

www.wikihouse.cc

Cool!!! Thank you for keeping us updated!!! Pics please, and video of doable!!

One of us, one of us… ![]()

Very interesting project, may I ask what size of building you are planning to make? Just curious the project spikes my interest ![]()

I agree with what has been said above. I almost strictly cut full sheet 18mm plywood. 10mm does not make sense. 6mm is the way to go, for clean cuts a straight cutting edge proved best to me. For faster cuts use an upcut bit. I don’t know where you are located but in the Netherlands (and I think all of Europe) you can get some great bits for cheap at Ecotools. They have a carbide professional line where most of the bits cost around 8-10€.

Also if you can wait a little longer it might be worth building the lr4 instead of the lr3 for your project. It looks like you will need to cnc a lot of large parts. The (from seeing videos on yt) speed of the lr4 is a significant upgrade.

Yes. ![]()

Check out this thread ![]() OP uses a system that I believe he says was inspired by wikihouse but put his own spin on it. He also might be able to provide cutting tips for this type of material + joinery.

OP uses a system that I believe he says was inspired by wikihouse but put his own spin on it. He also might be able to provide cutting tips for this type of material + joinery.

I think these large scale projects are so cool. Will be following along. Please make a build log!!!

Thanks for the shout out! Didn’t know there was a LR4 in the works. Here comes my condo building.

The .25 inch (6mm) is def the limit. Keep eyes or a camera on cutting - I almost started a fire with the first board I cut. I also changed bit after every board. Kept the old bits for smaller projects.

Would you be able to share your cutting profile for 18mm osb? Just so I have a starting point ![]()

Heh, every German car older than a couple years I’ve seen leaks oil. ![]()

Hey Aiden, I always went with around 2000mm/min, 3mm DOC, 24k RPM, 2-flute. The RPM is too high I guess for a 2-flute, but it worked. But you might want to start off more slowly and find your way to the top speed your machine can do, it really depends on a lot of factors.

The precision of “a German car”. A specific one that is within a fraction of a mm.

Sorry for the delayed response - I go with a DOC 5.25mm and 10mm/s for AdvanTech. That’s impossible for plywood but AdvanTech really worked out nicely - no voids, consistent density – not your standard OSB. I don’t know what is similar in Uk/EU… Anyway, I sometimes slow the speed during the actual job (turning V1 knob clockwise). I honestly just gauge everything by gently resting my hand on the router and if it feels like it is vibrating erratically, or digesting the wood like a coffee grinder with blunt blades – then I am going to fast. You can also tell with your ear – things start getting noticeably high pitched and whinny. These are all things as you spend time with the V1 (and your particular router) you start to pick up on.