Jackpot & Estlcam. When I start a job, I home x&y, then do a z-probe to set my zero’s. When I start the job, z drops into waste board and doesnt want to stop. I even use an extra 3/4" block on top of my material to run a test of the gcode. I had everything working for a moment, but not sure how I did it. LOL Im a little confused with Estlcam regarding z-axis origin, and clearance plane. Any good videos on this subject?

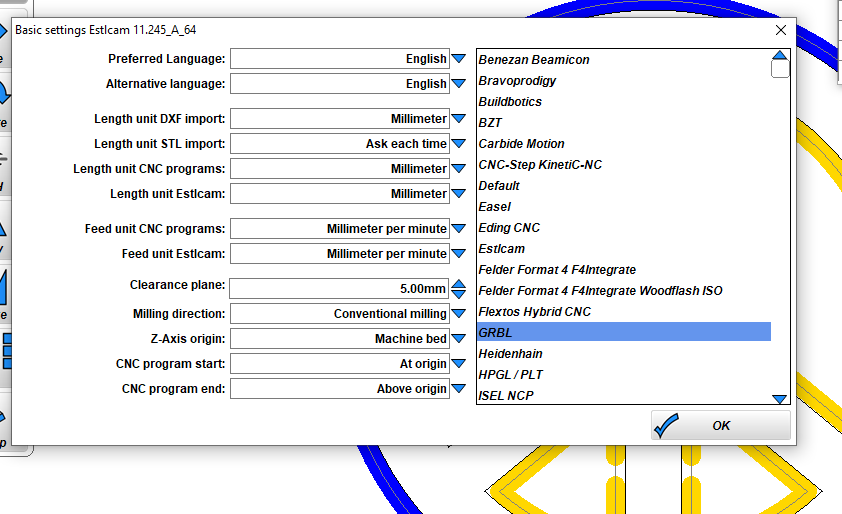

I think this is your issue. Set Z axis origin to “material upper side”.

Agreed. I read a post here in the forum saying machine bed, so I tried. In the past I always used Workpiece Top Side.

Fluid NC shows Machine 0’s & Workspace 0’s. What should they be when I have everything zeroed ?

I have discovered my problem. When I start a file, it pauses, at which time I need to be z-probing. When I do that all is fabulous.

Frequently I will cut the same part multiple times. Is there a way so that I dont have to probe each time??

take a look at the start code in the job. something there is causing you to need to probe.

I always set my work origin outside of the job, so the job itself assumes that the machine already knows where its home position will be, so as long as I do the work first, I can run any of the jobs that I have stored.

Where would the start gcode be located?? FluidNC? Estlcam? I totally agree but dont know where to look. TIA

I found it in estlcam which seems to be doing it on its own LOL. Might you know how to make changes permanently?

I found my Start gcode,and made appropriate changes and now works like a champ for me. FYI – I found it in Estlcam - CNC program settings - Program Start.

THANKS to all ![]()

Check out the Jackpot page.

https://docs.v1e.com/electronics/jackpot/#cam-settings

It then links to Milling Basics which provides further detail.