I can’t understand it in any way, help.

Where can I specify the height of the plate to set the Z axis to zero? For example, I have a plate of 2 mm, and I want to set Z to zero using the contact of the end mill and the plate. How will the control board understand after touching that this is a point of two mm and take this into account in the work?

Hello @ambhe, built a MPCNC Primo or something else? Already seen Milling Basics - V1 Engineering Documentation ?

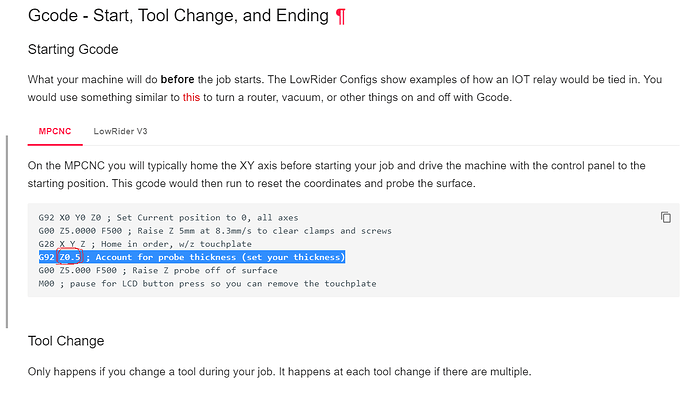

So, for MPCNC Primo, guessing… G92 Z2 ; for details see reference docs at G-code - V1 Engineering Documentation

Hope that helps, cheers!

Thanks, I’ll try

Typical Primo g-code for a touch plate 2mm thick would be:

G28 Z ; Home Z G92 Z2.0 ; Account for touch plate thickness G0 Z5 F480 ; Lift the bit off the touch plate

How to execute the code will depend on your process. If using Repetier-Host, it can be attached to a custom button. It can be put in a file on the SD card. If you are comfortable editing the firmware, it can easily be added to the V1 custom menu.

May or may not add to your confusion but Ryan linked my z-probe video on the shop page for the Tiny Touch Plate so maybe you’ll find it helpful too.

I’m setting the touch plate thickness in a macro button in cnc.js at about 3:15 in the video using the code highlighted by @azab2c and @robertbu

At G28 Z, the Z axis does go up a little and stops, while on screen Z set to 0. Why is this?

I think I added mine into estle cam and added a pause.

That’s what the ppl on here had recommended

The most likely reason is that your probe is already triggered and going up a bit is just part of the retest sequence. Start by sending an M119 to test the state of your probe. If it says triggered, then and assuming you are using V1 firmware, then you have a short in your wiring.

You want to run the test both with the clip attached to the bit and disconnected. One way I’ve seen a touch plate report triggered before the bit is touching the plate is if the signal line from the control board is connected to the clip, and the router bit is grounded. If this is your issue, you can simply reverse the two connections at the control board.