Success!

1x strut complete using upcut.

Just need to clean it up a bit.

Now to start the other 2x struts, this time with 2flute down cut at 10mm/s, 3mm/s plunge. ![]()

NICE!

Next time you get some endmills grab a single flute upcut. MDF doesn’t splinter. Then a 20mm/s cut in that with a 0.4mm finishing pass should leave a near perfect edge, much faster.

That was a single flute upcut, at 8mm/s, 3mms plunge, pass depth of 1mm.

I didn’t do a finishing pass however. That material is Masonite.

It did whistle while it was working, so maybe the slow travel speeds or 17000rpm?

I’m going to do the next 2 struts with a 2F down cut just to have the surface a nicer finish based on your recommended settings of 10mms/3mms, and put the Makita to setting 1, which is approx 10000rpm.

Instead of the down cut I would try just a larger finishing pass, or put the pretty side facing down.

It totally depends on your build but you can go faster and deeper. Try test cuts of course but you should have plenty of room for speed.

Didn’t think of turning it upside down ![]()

Ok so I’ll stick with a upcut. What would you recommend for speeds/feeds after it being successful at 8mms/3mms @17000rpm(setting 3 on Makita). What’s my suggested next move?

First would be to get your depth per pass deeper. 3-4mm is a good spot, but do that in steps to make sure your build can handle it, from that point slowly ramp up your feedrate.

Go back down to a 1-2 on the RPM.

Ok so I’m gonna go 2mm pass depth.12mm/s feed rate, 6mm/s plunge. At Makita setting 2 (12000rpm) which gives me a chipload of 0.06mm.

Does this sound good or could I push the feed rate even more?

Only ever increase one at a time. Start with depth until you eventually hit 3-4mm/s (you can turn the router down as well).

Ok so starting my cut,

At Makita 1 (10K rpm) I noticed it was a bit jumpy, as if it hit a knot in the Masonite. Raised the rpm 12K rpm(Makita 2), which did help, raised to now Makita 2 and a notch) approx 13k Rpm and that seems to have stopped the jumpness.

Is that the right way to go about it? Or is it telling me something else? Video below is after the rpm alteration.

Bumped to 14.5K rpm (Makita 2.5). Seems to run even more smoother now.

I can’t see it in your video.

Here is a single flute upcut 20mm/s at 13mm depth per pass. 1-2 on the RPM. https://youtu.be/gtrI1GG3TVI?si=lHy45AevSKqSM5vt&t=679

Is that Mdf in your video?

Maybe the Masonite (as it’s a hardboard made of compressed steamed woodchips) is why I had to bump the rpm? Maybe?

Googled:

Masonite is a thin, medium-brown board that is made from steamed wood chips that have been stretched into thin fibers and pressed together with enough pressure to form a solid board. Is considered a hardboard.

Very similar material.

Wait until you get your strut plates on to press too hard, maybe the RPM are needed without them. Once you get them on, I am confident there is a lot of headroom for more speed.

Prepped, painted… now waiting for it to dry.

PS. I’m no painter…… but thought I’d add a bit of Blue spray to break up the white.

Will look good once I have the led’s behind it ![]()

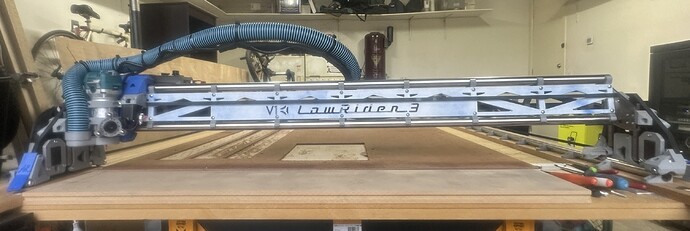

She’s coming up nicely, just got the bottom strut, led lights and a complete redo of the controller left.

![]()

Which hose is that?

Can’t remember where I got it from. Sorry