Try the test crown. I can’t really help with fusion CAM issues.

Crown test is ok.

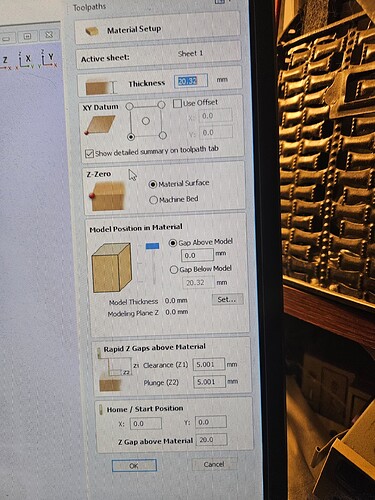

This is for vcarve not fusion ![]()

That means it is one of your CAM settings. Check your Z speed and Z rapid speeds. Starting level, Setting the Z=0 anything relating to height.

Yeah I have re-adjusted all that, will give this a go and see its depth and will report back ![]()

Ok so I have slowed everything right down, and still goes down 12/13mm

How are you setting your Z zero for each job?

Using touch plate

G38.2 Z0

G92 Z0.5

This is at start of gcode.

Can you cut and paste the first section of your gcode so we can figure out why it is not working. There has to be something before or after those two lines.

Check the setup on the toolpath side these are on the drawing side

Yeah it’s set as gap above model, 0.0mm

Just making sure i have had that problem it is like setting a start depth

Yep, I wish it were that cause that would explain everything.

2x downcut bits later and still no luck!

But that could be my fault, I think my Makita is set to 2 which is about 30,000rpm on ply. Might need to lower this for ply, but I’m still learning ![]()

The Makita is at 24k at 7, so something is wrong here. ![]()

Yeah, that’s using a tachometer with mirror reflector on spindle.

So ![]() , I have now set it to 2 which is reading 14k

, I have now set it to 2 which is reading 14k

I thought the Makita top end was 30k, told you pretty much use that speed for everything except acrylic.

Then I was told between 1-3

At 2.5 I snapped a bit.

Dropped to 2 now which is reading the 14k

Depends on what you are doing. I used to use burr endmills, they need 24k. I also always try to maximize speeds of at least go a little faster, then you are getting back into 24k territory. ![]()

Well I’m just trying to cut the struts lol using 1/8” 2flute downcut from v1e shop

Ok so it seems my tram is out. Left side is higher then right side. By approx 1-2mm, but I doubt this will cause the 13mm deep hole instead of 6mm. ![]()

![]()

Just can’t figure this out, gcode seems ok. Steppers move correctly. X gantry is perpendicular with bed. Wtf!