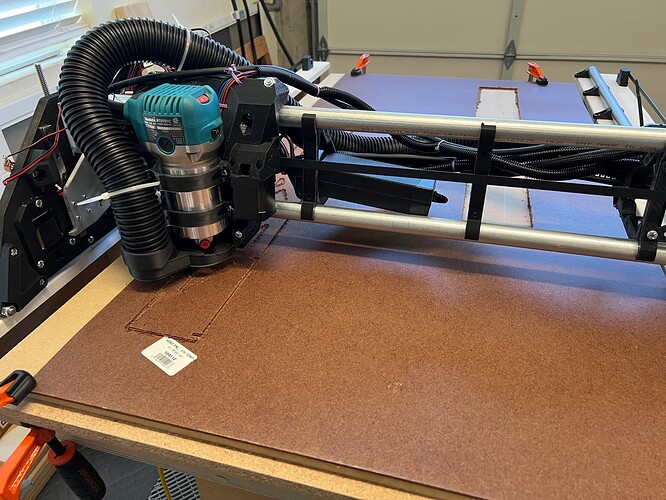

I recently started building a Lowrider 3 and purchased my YZ plates from V1Engineering, Today I was starting assembly and when it came time to install the Z Drive mount into the YZ plate it didn’t fit. I’m not sure why, but it appears the YZ plate’s Z drive mounting hole is too narrow. I’ll be able to file it down or sand it down to make the Z drive mount fit, but I found it odd, since all the screw holes line up just fine, and my printer is well calibrated. I measured the Z drive mount at 58mm wide (which I assume is the targeted size based upon measuring it in the Prusa Slicer) and the hole in the YZ plate is right at 57mm wide. Worn tooling? Anyway, was curious if anyone else has had a similar problem? (edit I see now one other report of the same issue from Aug ‘22) Otherwise, so far the assembly is going well. I’m targeting a smaller table than many build, 2’x4’ mostly because I’ll only be building smaller projects and somewhat because I don’t have a lot of storage space for a larger table. I appreciate the design and look forward to using it.

Very strange. I wonder if @vicious1 has had any other reports.

I had a similar issue with my LR3 build in progress… but i thought that was due to me painting the MDF.

I had to do just a bit of modification on my plates.

P.S. Welcome to the V1 community!

I did paint mine too- but oil based paint, and no other evidence of any swelling - I’ll sand them tomorrow to make the hole wider.

I remember us having a little trouble getting the motor mounts into the holes (I had to rotate them to get them in). But I don’t remember sanding anything once it was through the hole.

Same experience here.

I can go do a test fit in a little bit. Taking a note. YZtestfit

Thanks- I assume just filing/sanding/rasping the hole to the right width for the Z mount won’t create any problems. I’m just about ready to do that.

Not at all.

Checking mine now.

Yup, the Y mount is perfect, the Z mount is a little to snug, I could have pushed it in but taking it out might not go well.

Good idea to sand it out a tiny bit. Remember snug is good here, anchors it in really well. If we stay with the LR3 longer term I will edit the printed part.

So we maybe won’t? Interesting… ![]()

Thanks! I was concerned that I had done something wrong in my print- or that there was a manufacturing problem with YZ plates. I knew I hadn’t swelled the MDF with the spray paint. I too had no issues (other than just orientation:)) with the Y mount , but couldn’t get Z mount to fit. I’ll go easy on the sanding and make sure it stays parallel and snug. Thanks again for checking it out.

I’ve got the urge to get a spray bottle and spray Ryan for saying this. Like, no, bad Ryan, squirt squirt. ![]() And yeah, I am a bit antsy and impatient.

And yeah, I am a bit antsy and impatient. ![]()

Same here as well.

A little filing and it all went together just fine, Ryan’s design is actually very very good! I am cutting the trusses now- but need to work the fusion software some more to get all the setting dialed in. These first cuts were on a piece of not too flat hardboard. while it worked, they aren’t nearly as nice as I know the machine is capable of doing with proper setup and well executed cut files