Made some more progress.

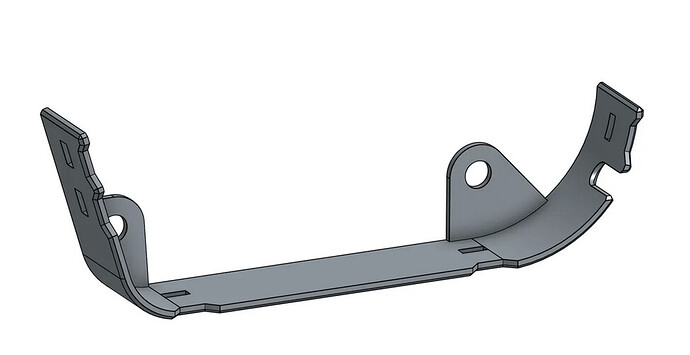

Got the leadscrew stubs printed and installed.

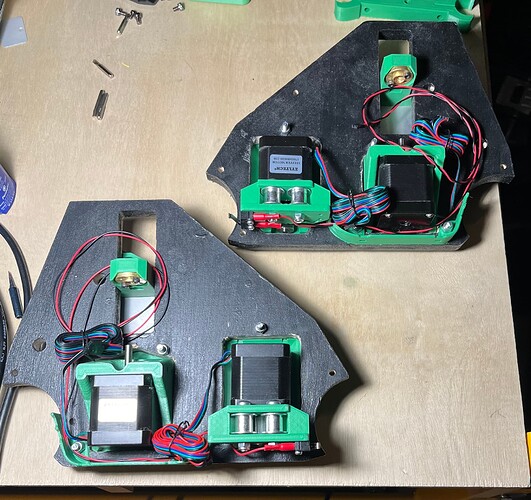

Decided to get to work on the YZ plate assembly. Started out pre-threading the wood screws about 1/4 way.

Started installing, center of rails working out. Since I briefly fiddled with the stops and thought “Since I’ve started and don’t have back side access to the screw holes, whats the best way to pull the stops…?” Then I decided to use the wood screws as a tool to remove the stops. A silly thing to wonder, in hindsight. You can see that in the picture below, the wood screws are in the upper stops just before i pulled them out.

To install the linear rails, I installed one screw in the center of each rail, then pulled the stops out of the rails.

I then installed screws from the center out on one rail, then did the same on the other rail.

At the end, I loosened the screws in one bearing block then re tightened them. Repeated with the other block. Both finished plates slide decently. Not perfect- but completely usable.

The finish I applied is horrible.

When I first started working on the build, I went looking for an acrylic paint and finally settled on one- but would choose something else next time. More on that later.

That’s when I ran into an issue- the Z drives and Y drives wouldn’t fit. I wonder if the paint caused a bit of swelling in the inside cutouts for them. I spent a bunch of time first scraping off the acrylic paint inside the cutouts, then sanding and even using a little saw to clean out the corner radius of all of the cutouts. Took quite a while and uglied them up a bit.

Part of the thing about that acrylic paint I used- it was still tacky a week after going on.

If the big box “paint expert” tries to steer you to this for painting MDF… just say no.

I have a satin version, but forgot to get a picture of the can. So stock photo it is.

In thinking about it, “Soap and water cleanup” must mean it’s water based. Probably not the smartest day I’ve been on the planet when I bought that and painted the panels.

I should also have had hangers or some painters triangles. Fail to plan, plan to fail. At least it was a minor failure and recoverable.

I hadn’t yet taken the tiny handheld saw to clear out the corners when I took that photo. It was another 10 minutes per plate.

So, I guess you can say I’ve already got my “soon to be an LR3” machine dirty before it’s even fully built.

I stopped here to make some machine noises, as it seemed appropriate.

Then I got back to assembling the plates.

I used Peter H’s excellent cable tidy add on.

https://www.printables.com/model/766799-lowrider-3-yz-cable-tidy

I still need to find some tie wraps to get things better cable managed. I also intend to mark each cable connector in silver sharpie with where it goes- in a likely futile attempt to keep it all straight.

I also realized that I hadn’t printed the Y axis rollers (The back ones- that have two bearings in each end). So the printers got some more run time.