Finally ready to do some aircuts and of course there’s a problem the z axis rises througout the cut what could cause this I’m using jackpot with fluid nc and estlcam v12 I’ve tried flipping connections around and tried reversing the z axis in estlcam settings

What do you mean by “rises”? It ends up higher? That’d be an unusual problem.

Yes it rises with each pass I’m air cutting my struts so I can watch the movements si instead of the bit going deeper it gets higher

Does it jog in the correct direction? That is +Z goes up and -Z goes down.

Yes that’s why it’s puzzling

Attach your gcode.

I’m not sure how to do that it’s the strut plates for v1e instructions

You can upload the file here. You might need to put it in a zip file.

I’ll work on getting it if I can figure it out very new to this

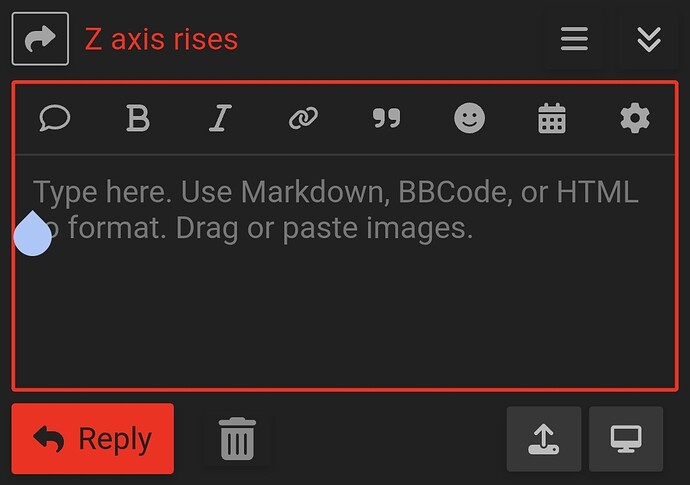

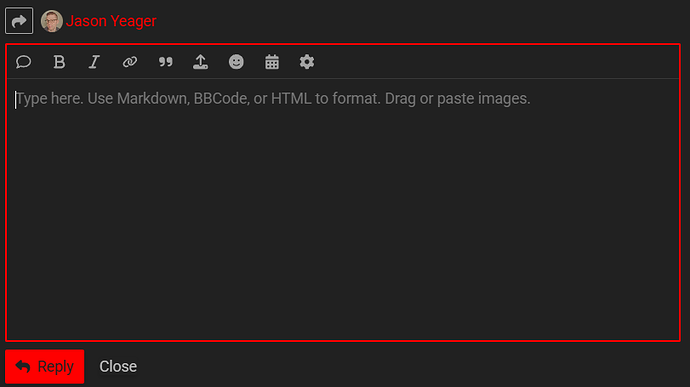

It’s this icon:

![]()

On mobile, it’s the icon in the bottom right with the up arrow.

In a regular browser, it’s in the toolbar towards the middle.

That I know it’s the gcode I’m not sure of

How are you running the gcode if you don’t have a .gcode or .nc file? That’s what you generate out of Estlcam.

I downloaded the strut plates file on estlcam to create gcode loaded sd card into jackpot controller my terminology might be off like I said I’m very new to this and appreciate all your help

Ok, no problem. I’m looking for the file that you loaded onto the SD card.

It was in the lr3 instructions strut plates 2ft and 4ft dfx file

So, a DXF file just defines a 2D image. The purpose of CAM software like Estlcam is to take that 2D image and convert it into gcode instructions. I want to look at the gcode you created with Estlcam to see if there are any issues with it.

If you loaded the DXF file onto the SD card, the Jackpot doesn’t know how to run that.

I’m happy to explain and answer any questions but it may be helpful for you to review the milling basics page as well as the Estlcam basics. The Overview section of the Software Basics page may be helpful as well.

Strut Plate 1400mm.gcode (314.5 KB)

i hope this is what you need

Strut Plate 1400mm.zip (13.5 KB)

The gcode is wrong. It starts at -7 and goes up to around +7 at least for the holes. It should start at 0 and go to a negative value slightly more than your material thickness.

I would double check your Estlcam settings in the Estlcam basics. I’m wondering if maybe you don’t have Z-axis origin set to “Workpiece top side”.

The good news is I think your machine is working properly. It sounds like it’s doing exactly what the gcode is telling it to do.

I’ll check on those things thank you for the help