I should also note that I wouldn’t start with cutting the strut plates. You should do some testing in foam to understand the process first. Foam is more forgiving and a cheaper way to learn. It can be something as simple as cutting out a small square. If you haven’t already drawn the test crown, I would start there. You don’t need the strut plates for drawing the crown or cutting foam.

I was air cutting to get an idea on how it would go I have foam to test with and I’ll do the crown tonight

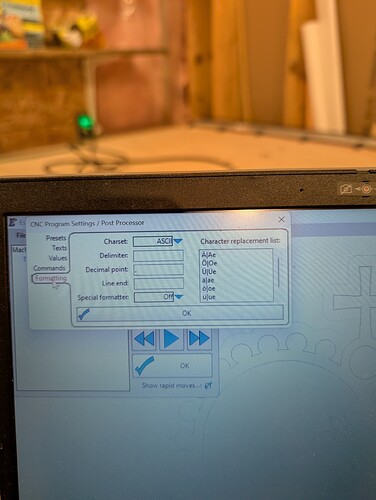

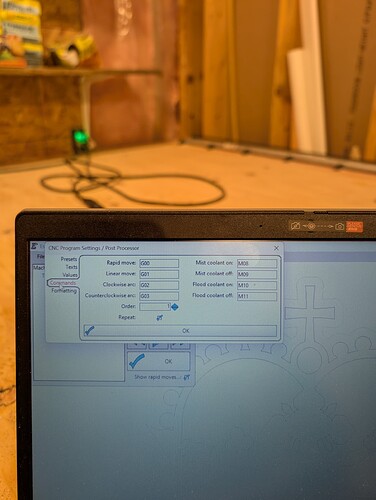

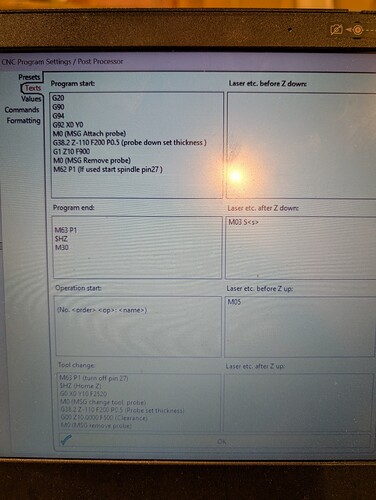

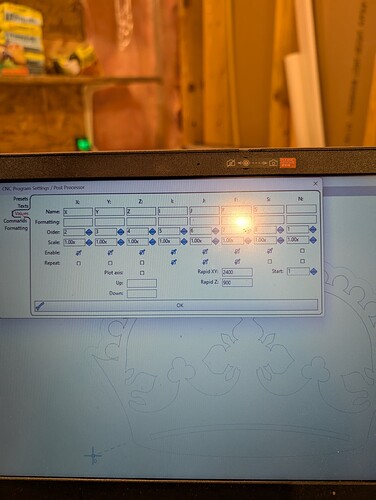

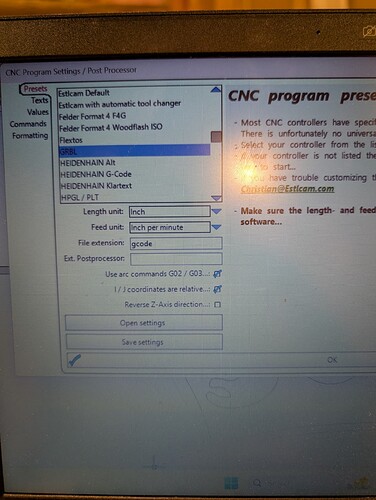

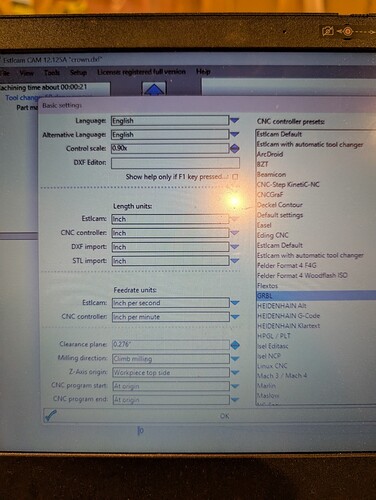

I would set it up to use mm instead of inches as shown in the documentation. While technically, we can make that work with an additional change, I’d stick with the recommended settings at least for now. I’m in the US so I’m used to inches for most things, but for 3d printing and CNC, I stick with metric.

Ok so change everything to metric any idea why that gcode would be bad it was right from v1e site I want to cut it in foam I’ve been messing around with this thing I’m getting frustrated with it

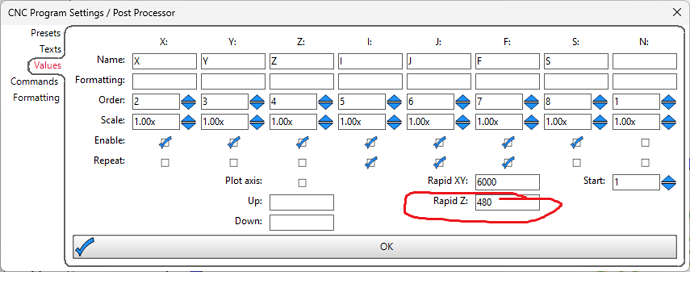

Consider temporarily setting Rapid Z lower, try 480 instead 900 until you get good air/real cuts.

Also, was/is your router bit fastened tight enough? Are you using 1/8" router bits in a receiving 1/8" collet+nut? Asking, because have previously seen 3mm bits incorrectly used in 1/8" collets that end up slipping. Also, I’ve personally fluffed up and not correctly tightened/torque a router bit before that resulted in cut/engraving getting fainter throughout the job. Ended up spending bunch of time releveling the gantry before realizing router bit needed to be secured correctly ![]()

A post assembly Drag Test macro to identify Rapid Z limits could be useful… Goal would be to identify at what point the assembly starts missing steps. Knowing this could help Makers determine whether they need to fix/tune something, and/or give them confidence about what’s a safe operating margin for the size/materials/power/config combination they assembled.

Hope that helps, cheers!

What about changing z-axis direction on the preset page. It’s a checkbox towards the bottom. Then I would try an air cut again to see if that corrected the issue.

I tried that didn’t work

When you tried the haircut did the probing go in the proper direction at the start of G-Code run?

Voice dictation error. Air cut

Where on the V1E site did you download gcode?

The assembly page there is a 2ft and 4ft

Please provide a link. I do not see them.

probably not the right place to get them

Do you have a Lowrider 3 or 4?

Lowrider 3

Ok, given that the Lowrider 4 is the current version, I didn’t realize you had an LR3.

Either way, those are DXF files, not gcode files. Those files are fine but you need to do the CAM side to generate gcode. Your problem is not with the DXF files, it’s with the generated gcode.

Time to watch the estlcam videos again I must be doing something wrong thank you very much for your time and help greatly appreciate it