Just keep at it, you’re doing great so far. Electronics can be a bit picky, but we’re all here to help you out with any trouble.

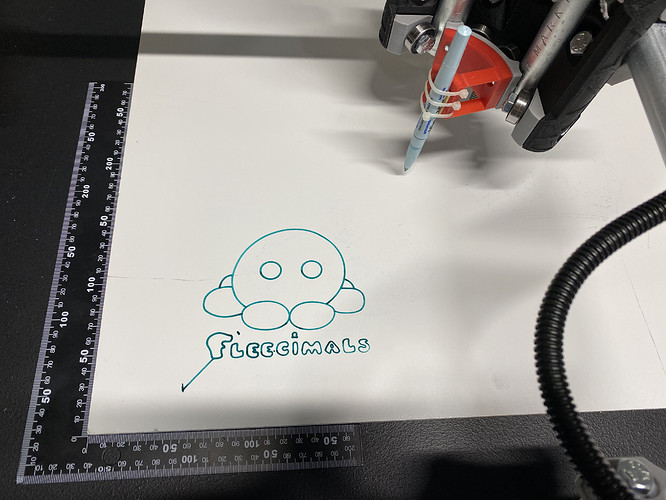

Thank you @Cobalt! I got the electronics wired up this morning and initial testing looks good.

OK, starting to get a workflow going on my Mac…

- Took an Adobe illustrator file (my daughter’s from a lasercut in my old lab) and exported as SVG.

- Imported SVG into Lightburn, scaled it, cleaned it up a bit, and saved G-Code.

- GREPed the G-Code to change the Fan Speed (M106) commands (which are I guess how we control LASER intensity?) to Z axis moves to raise and lower the pen.

- Moved to MPCNC via SD card and voila!

Now I need to start figuring out sourcing for CO2 laser tube, power supply, chiller, etc. Anyone with any experience with reliable and inexpensive (OK, I know, I probably get one or the other  ) vendors?

) vendors?

Have you considered doing a laser diode as an intermediate step? They are a lot safer and tolerant of goof ups. Some of the 2.5W ones are about $50. Ones that support 12V PWM spuld just connect straight to your fan output.

I go back and forth in my thinking on a diode laser as an intermediate step. Yes, they are cheaper and easier for sure. But my goal is to be able to cut wood (at least 1/4 inch plywood) and acrylic (including clear) as well as fabric. Diode lasers from what I’ve seen are essentially useless for most of that. Only good for engraving. I may be wrong, of course. CO2 is what I learned laser cutting on. But yes, more expensive and more complicated and more dangerous. So… I’m open to starting with a diode if there’s anything useful I can do with it.

It’s your build and you have the right experience for that. I haven’t messed with a CO2 setup. But it seems like it is stacking a few more layers of potential problems in too. I would consider the tiny laser a debugging tool, or equivalent to a textbook to learn the electronics and stuff. But you may not need that, given your experience.

The diodes do pretty well cutting small stuff with air assist. It will never be a CO2 though.

Just my $0.02. i am definitely interested in the co2 build you’re sharing.

Most of my electronics experience was in the 1970s @jeffeb3.  Like I said, I go back and forth. But with my daughter’s wedding coming up in less than 2 weeks, and me traveling a couple weeks after that, I won’t even be able to rush the decision if I want to.

Like I said, I go back and forth. But with my daughter’s wedding coming up in less than 2 weeks, and me traveling a couple weeks after that, I won’t even be able to rush the decision if I want to.

Some of that involved a neon sign transformer, so I do have experience with high voltage. ![]()

Man, I’m not sure what y’all doing being on this forum…

Some of this stuff, electronics knowledge from 4 years ago is only a hint. 4 decades? Well, kudos anyway.

For the CO2, I think that with things like dual endstops, where you can be sure that the gantry is square you should be OK. Biggest risk there is missing a mirror and melting your core or something. (Assuming that you’re smart enough not to stand anywhere near the CO2 laser path.) Well, that and the ever-present danger of fire.

A diode laser should be able to cut 1/4" plywood. Not sure about thicker, but not sure about the CO2 laser either, depending on the focal length of your cutting lens. The diode will need a few passes to do it, is all. Clear acrylic is not gonna happen with a diode laser though. Not a chance.

If you are going to cut acrylic, you will need ventilation! The products of combustion for acrylic have some very toxic stuff in them, and you will absolutely not want to breathe that! There’s a good reason that most laser cutters are enclosed and ventilated, in addition to the air assist. So far, I haven’t done anything other than wood/bamboo with my diode laser.

Yep. I plan on fully enclosing it in a vented cabinet and providing air assist. Even if I do Diode. The CO2 laser I used to use would cut quarter inch plywood in one pass, at a fairly high head speed. Not venting wood cutting would smell like a campfire in my basement, so yeah. Needs to be a sealed cabinet vented outdoors.

As for the wedding… well, we had a 1 year COVID delay, so it’s been planned to death.  Besides, I’m the father of the bride. My responsibilities are basically walk her down the aisle and sign the check.

Besides, I’m the father of the bride. My responsibilities are basically walk her down the aisle and sign the check.

Oh, also… aggressive venting greatly reduces the risk of fire. Basically between the air assist and the venting it blows the fire out. Because yeah, you do get some fire sometimes. Oops.

My 40w neje diode laser claims to be able to cut 22mm wood. I haven’t tested it yet! (Don’t know if I’ll ever dare to…)

From the laser’s point of view “wood” <> “plywood”

The glue in plywood is much harder to burn through than just the dead tree cells.

In Today’s video (#4) I complete the electronics and wiring of my MPCNC! As you saw in the pic above - it works! (Watching the robot draw on video is way more satisfying though.  ) I’ve even started figuring out the software.

) I’ve even started figuring out the software.  Next step is figuring out what kind of LASER I want. (Yeah, I want a CO2 so I can cut wood.

Next step is figuring out what kind of LASER I want. (Yeah, I want a CO2 so I can cut wood.  ) In the meantime we’re preparing for my daughter Michelle’s wedding in less than a week

) In the meantime we’re preparing for my daughter Michelle’s wedding in less than a week  but the build must continue!

but the build must continue!  (Because Michelle wants to use it too.

(Because Michelle wants to use it too.  )

)

Hey… you want to know the perfect wedding gift for Michelle? Check out her website. And hey, if you wanted to buy one of her adorable critters - many of them made from LASER cut fabric - that would totally make her day too! (As soon as she gets back from her honeymoon.  )

)

Edit: Ah, the post has been reviewed and is now visible ↑

Thank you to whoever released the post.

Well, I tried to post my latest video yesterday, but the system “temporarily” hid it because apparently I unknowingly broke some rule or something.  I’m sure you can find it on my channel based on previous video posts if you want to see it. Basically sped-up electronics/wiring, then some tests with a pen.

I’m sure you can find it on my channel based on previous video posts if you want to see it. Basically sped-up electronics/wiring, then some tests with a pen.

I like your videos. Is there any reason why you’re posting them on a site like gab, which has often been associated with things like antisemitism, violence, and the far right, instead of more popular, maintream options?

By people and organizations that have been trying to shut down Gab for years.

I have been on Gab since the beginning and yeah, there are a few idiots, but I’m an adult and can ignore them. I have had no issues and folks there appreciate my videos. I tried a few other video platforms that did not accept the kind of videos I make, and YouTube is just a mess and I just don’t want to play all their algorithm games.

Thank you and I’m glad you like my videos. You do not need to join Gab to view them, so please continue to enjoy them.

In my best Austrian accent: "I’m back."

Just a quick update:

My daughter’s wedding was lovely, and then I went on vacation. Came back and tried to catch up on all the usual Fall preparations for Winter, but now it’s time to start working on the ol’ MPCNC again.

So… yesterday I ordered about $1,000 worth of CO2 LASER components.

Some may not be here until mid-November, but I’m kinda committed to getting this going now.

Some of my LASER components have started to arrive, so it’s time to complete the construction of my MPCNC CO2 LASER cutter! In today’s video on my channel I head into my workshop to build the bed for it out of MDF, wire cloth, and sheet aluminum flashing.

I break out the power tools to build an (overly heavy  ) enclosure for my MPCNC LASER cutter. (And also deal with home center materials shortages.

) enclosure for my MPCNC LASER cutter. (And also deal with home center materials shortages.  )

)