My desk.

It’s one of the most time consuming and complicated things I’ve built over the years. It needed so much planning for everything from getting hold of the timber to milling it, jointing it, gluing, finishing, modifying the sit-stand frame etc. It was a big jump for me in terms of both the quantity of different tools I needed to get and the amount of stuff I needed learn how to do.

The top is Fijian Yaka that my Dad imported. The base is a sit-stand frame that I cut up and reinforced with some heavy wall box section.

It’s extremely solid, doesn’t wobble like the other sit-stand desks I’ve used and the wood is utterly gorgeous.

That or the 2.5m/8’ tall cat tree that I overbuilt so much that I can sit on the top perch…

What a Lovely desk!!! And a glorious cat tree!

Not CNC made, but made for CNC…

What: My electrically operated Tilt-away, Roll-away table base…

Why: It solved some major problems for me (moveable, space saving). And it is something that was designed and created pretty much entirely in my own head (I hadn’t seen anything remotely similar to this idea before starting, and still haven’t seen anything quite like it since).

Such a great idea!!! Way to go!!

I always think that the last thing I’ve made is the best (more on that in a minute), but I do have fond memories of one of my boats (the Goat Island Skiff) which was launched exactly 29 years ago last Sunday has had the biggest impact. It was designed by my friend Michael Storer, and built when I had little time and very few tools.

I borrowed a friend’s Triton to rip the timber to size. In the early 2000’s my website went mildly viral, which made Michael and I a little bit internet famous, and was the catalyst for thousands of other builds.

But that has made me think of the OzRacer. Michael was staying with us for a couple of weeks, and I casually said -“why don’t we see if we can build two boats for $200.00 in two weekends”, so we did (based loosely on what was known as the PuddleDuck). Things got a bit out of hand with that one too, and they grew to twelve feet and the OzGoose is now racing internationally with particularly large club fleets in the Phillipines!

Great story to go with a couple of great boats!!

So when it comes to complicated (and recent) projects. I have a vast stack of things to do which is rather keeping me away from CNC and building things for “fun”.

I did finish the “Little TV” wall unit thingy just before Christmas. No CNC required, but if you go back you’ll see I’d made the doors just in time to be interrupted by the arrival of @vicious1 's package full of LR3 bits. Made from construction timber milled and laminated by yours truly.

The “Big TV” thingy is in an advanced state, but that can wait a week or two! ![]()

Very nice! Clean and modern…I like it!

You know you and this topic are a breathe of fresh air here!!! Thanks for joining our group!

Awww shucks… ![]() Thank you dear! I’m grateful to be apart of such a group of well rounded individuals.

Thank you dear! I’m grateful to be apart of such a group of well rounded individuals.

Hey @RockinRiley… You didn’t answer the question!!! ![]()

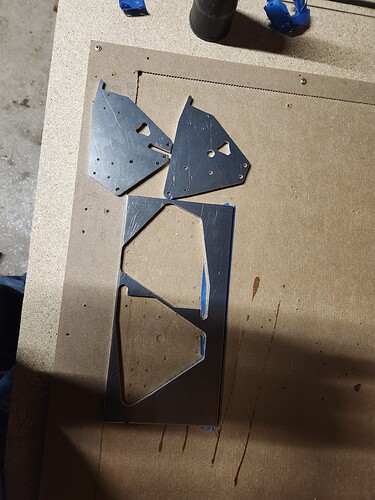

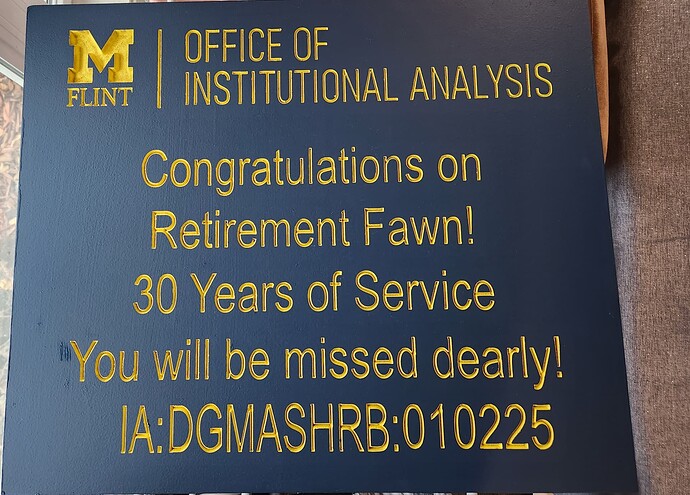

Both of these. The sign they were so happy with they flipped me a 100

The side plates because it was the first time doing anything but wood ![]()

Those XZ plates look great! Wonderful looking sign, with some fine detail work!

This belt grinder conversion for my bench grinder has been a game changer to have in the shop. It’s been awesome for metal working but it’s also made a big improvement in how I sharpen my woodturning tools.

I ordered the plates from an online service but when I get around to making a 2nd version I’ll mill them out of aluminum myself.

Wow, nice looking machine there!!

Because it made this possible…

and because I can say no one else has one exactly like it

Beautiful Machine and an AMAZING costume!!!

So, how about your answer, then? ![]() What are you the most proud of?

What are you the most proud of?

I knew this question was gonna come back on me…I honestly can’t pick…I’m not much of a woodworker or anything like that. Let me think on it and I’ll get back to yea.