Working on a Dining corner bench

No CNC, just slapping a bunch of cabinets and sheets together…

By the way, I’m looking for ideas for the cabinet doors, if anyone has some CNC design idea or samples, just let me know

Working on a Dining corner bench

No CNC, just slapping a bunch of cabinets and sheets together…

By the way, I’m looking for ideas for the cabinet doors, if anyone has some CNC design idea or samples, just let me know

Lots of small details and adjustments later…

The lowrider served well, as always… Quickly made some templates

Still looking for ideas for the cabinet doors ![]()

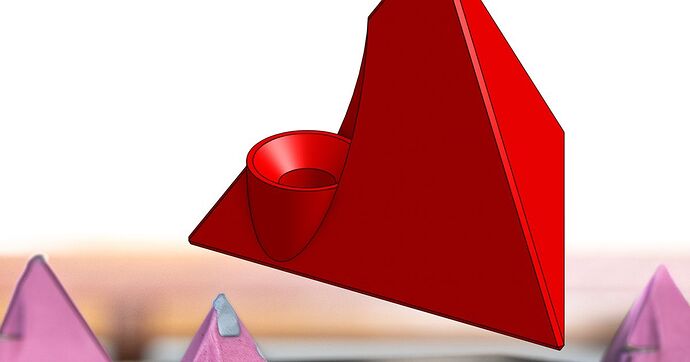

The base for an automatic cat feeder. Made using a cereal dispenser, a servo and (of course) a tiny esp32 running esphome.

Serveral hours to 3D print, 15 minutes to cut and stack.

Do you (or anyone else) have a good resource for learning about the different sealers and application techniques? I know nothing about sealers and stains etc but I feel like I should lol. Currently I just use a linseed oil + bees wax combo liquid which is nice but I need to broaden my horizons lol.

I have these really cool ikea cabinet doors that have a 3D wave texture on them, something like that would really pop against all the straight edges of the cabinets ![]() LAXVIKEN door, white, 231/2x251/8" - IKEA

LAXVIKEN door, white, 231/2x251/8" - IKEA

I may look into making a python script to generate wave patterns based on your own params, adding that to the TODO list lol

You jest (and I LOLed) but I seem to always get a cut on a hand/finger when I’m in the garage, I would totally benefit by having TP all over the place lmao

I made something similar for a little gift box

I made an howto a while ago, no pyhton involved, just some blac and white pictures with gradients

I decided to make a small gift box, mainly as an exercise in modeling and 3D machining I learned quite a lot concerning the design process, and wanted to share a kind of tutorial This little project is a cool practical gift, and will cover a lot of “not so basic” modeling and machining techniques I hope this long post will give you an incentive for your future projects, and maybe help you learn new tricks along the wayF3D file included for anyone willing to help …

I’ve seen these doors, they looked like a cool cnc project, but my wife just don’t like them ^^"

I’m thinking maybe something like this ones

BJÖRKÖVIKEN Porte/face de tiroir, brun placage chêne teinte, 60x38 cm La façade BJÖRKÖVIKEN est en placage de chêne foncé, un matériau naturel offrant un aspect vivant et chaleureux, avec un grain qui fait de chaque porte une pièce unique. Le sens de...

Or white mdf backpanel with some oak tassles to match:

Do you (or anyone else) have a good resource for learning about the different sealers and application techniques? I know nothing about sealers and stains etc but I feel like I should lol.

This book may be geoblocked - but it is probably exactly what you are looking for.

Hmm, I usually polish my wood by hand and then wipe it off with a paper towel when done. ![]()

It might be hard for some of you to remember, but October was “clean up the shed” month at my place, and when last I posted I think I’d finally moved the wood vice from the compressor bench, and that meant moving a heap of timber that I had stored to trim off my workshop drawers. I seem to have been doing stuff every day, but really haven’t got terribly far I’m afraid.

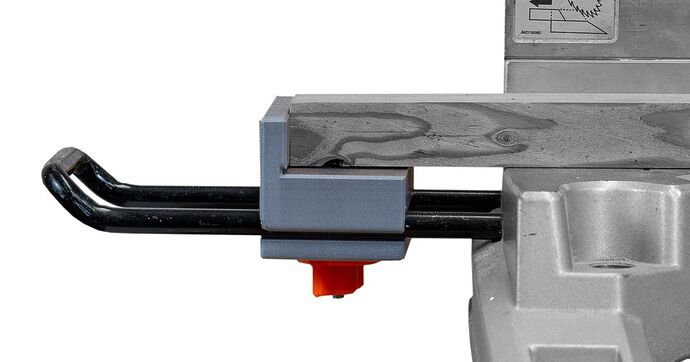

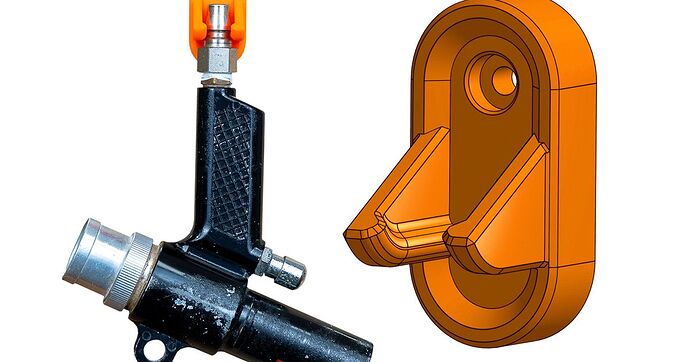

They were nice, but they needed threaded inserts so I made a gadget to fit to the drill press to help with that.

Which was fine, and it was easy to make a jig to hold the parts in to keep them level.

and then I had to cut all the dowel bits to equal sizes…

All of which distracted me from the job in hand, which was rebuilding the compressor cupboard and drawers and making some new fronts for them (painted MDF). Which reminded me that I didn’t have a way of keeping the “other” side off the bench while I rolled the paint so…

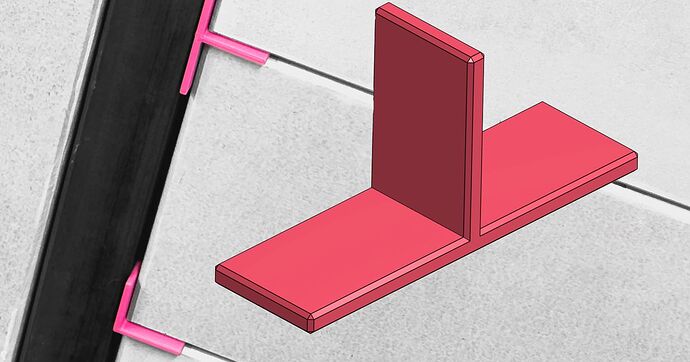

To hang the drawers and cupboards I made some spacers…

And some jigs to mount the handles in the new panels…

Then I installed some hangers inside the cupboard to tidy up the air tools…

But it all kind of worked out in the end because the car lives in the garage once more, even if the other half of the space is untouched.

Of course you blokes sent me down a rabbit hole inadvertently

and I had enough time to put together an photo montage for a competition “Why I live where I live”

Now I’m off to have a good lie down, and contemplate how long it’s going to take to clear up the rest of the shed. I would SERIOUSLY like to be working on some V1 stuff before Christmas, but at this rate I can’t make any promises!! ![]()

Wow, that‘s more than I can do in a year… Love the pyramids, maybe one could print just the tip in TPU? ![]()

Also, a drum sander is still on my wishlist. ![]()

maybe one could print just the tip in TPU?

Now that you mention it - I reckon the whole thing could be TPU - that would definitely work.

I’m off to get some sleep before I tackle the stack of timber I cut for bee hives last year!

I’d try that out but my Core One is cranking out LR parts for another order. ![]()

Brandon at Inheritance Machining calls those “side projects” and keeps a count in (most) of his YouTube videos. You cranked out a bunch of them on the way to completing the main quest. Well Done!

Now I’m off to have a good lie down,

Well deserved! That’s a lot of progress.

Wow, that‘s more than I can do in a year…

Heh, I was thinking the same thing about my (lack of) progress.

![]() going through and repairing the garage/shed.

going through and repairing the garage/shed.

Sometime since the last time I was in there using the tablesaw, someone pried off the hinges to door to get in, then set the hinges back in place to cover their tracks. That places the break-in from the second week of September to last Friday. Discovered when I went in intending to change my wheels for my winters.

Missing a mini-bike, my welder, my aluminum hydraulic jack, some martial arts equipment and various tools. Anything that was in a carry case is gone. Plunge router, air tool assortment.

A few grand in missing stuff, but not sure I even want to talk to the insurance.

I have a fix in place for the door, so at least they can’t just walk back in, and an ESP32 cam set up to watch, in case they just pry the fix out, but the panic now is an out of town trip where I need my winter tires… at least they didn’t take those…

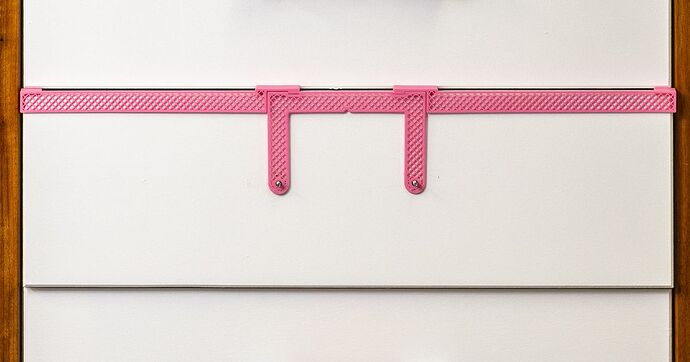

Cable management day…

Added a plug to the worktop (3 years after installing it)

Had to disassemble the whole bench to route the wires behind it

Also installed a power strip inside the gutter

This really sucks ![]()

Life’s been busy lately with lots of little projects.