Today, after well over two years since the last time I backed up my laptop, which is my primary computer, the workhorse with everything on it, I finally got a backup made. It added about 120 GB or so that had not been committed. It’s the little things, sometimes.

The door or the cat? ![]()

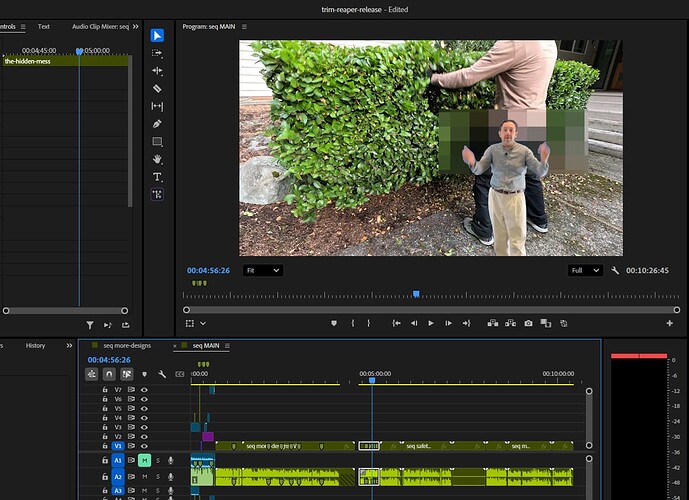

Thank you for the feedback @DougJoseph, totally agree! That part looked incomplete, made some edits. Unfortunately, I’m still polishing off this video…

I wouldn’t need to fix cat’s door if cat was not there, right? ![]()

Dog is like 40kg and he loved to take a look in the kitchen, but could see a bit more from a bit higher, so he was using cat’s gate to stand on it with front legs. So it cracked and came off a bit, so he probably thought “it’s broken anyway” and shredded it to pieces ![]()

@azab2c what’s so critical on your bottom that you had to pixelate it in the video?

My current project:

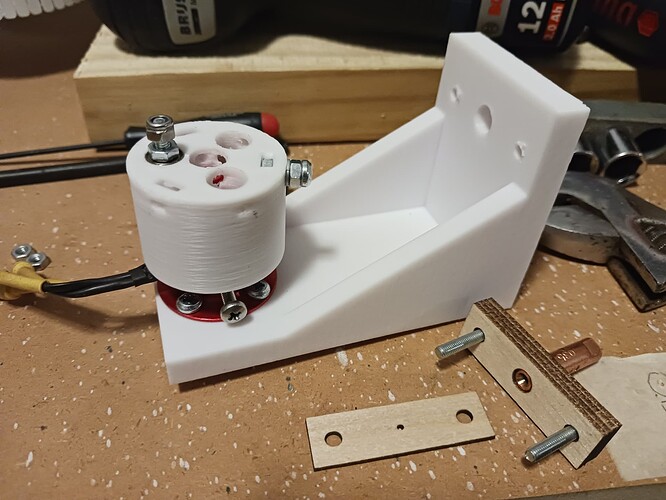

I have fence mounted solar panels that power our backyard (outdoor kitchen, lights, hot tub) and wanted to maximize the potential. designed and programed a solar tracker board. The new versions came in yesterday so I can get it installed to replace the old one I had. This is V3 Custom. I also put together one that uses all off the shelf parts and hats for an Arduino Uno.

Both have printed inserts for the enclosures and I2C displays to show the status and sun values for tracking.

Oh that should be cool. If you remember let us know how much improvement you get with the tracker.

The same for me. My first cnc was a needle cutter. It was an oversized MPCNC that I built at the Middle School I taught at. Lots of students built gliders and airplanes that were cut out on it.

In the land of the giants ![]()

![]() Compressor serviced.

Compressor serviced.

That wasn’t even on my list, but since I had to get it out of the cupboard to rehash the cupboard, it seemed like an obvious ten minute diversion.

How hard can it be to change the oil, drain the water, clean the air filter and pat it on the head? VERY. There’s a sign on it that says “check fan belt every 50 hours”, and since this is it’s ten year checkup, I thought that might be smart.

The fan belt cover is held on by a mass of hidden clips and screws, one of which requires the pressure switch mechanism to be removed for access, the other is behind the cylinder head. (I broke that clip, and the mounting bracket for the other before I discovered them). A few hours, some aluminium angle, pop rivets and some fancy filing later, it’s all back together and ready to run for another ten years.

But it’s lunch time and I haven’t started anything productive…

my boy’s clutch… yep, that’s what the problem is.

![]() Old pipe clamp vice removed and little wood vice fitted to bench in its place.

Old pipe clamp vice removed and little wood vice fitted to bench in its place.

It was a complicated little job, made even more complicated by the fact that the rack for the pipe clamps was filled with scrap timber destined to make trims for the workshop drawers. Now the floor is cluttered with them, so I guess I know what I’m starting on tomorrow.

@vicious1 Sadly I have changed a bunch of things at the same time (doubled the panel capacity) and don’t have any good baselines for it. I may be able to do something this next two weeks as I will be out of town so I may leave it not tracking for the time and then turn on the tracking so I can baseline the system.

What I did see when I had just one bank running was much early generation in the day. Since my panels are not set facing due south, I get early sun and then a little later production as it travels over.

I guess I should have mentioned this a week or so ago. Grand-daughter has commandeered the “Laverne L” (from the Laverne & Shirley TV show) as her own… it’s now the “Layla L”. Anyway, for the last two or three years, when football season and homecoming rolls around in North Texas, she has “needed” an ever-larger corsage… which she crafts all by herself. She does buy/scrounge the materials of course… but I’m her “go to” for the “L”. Sized to her liking and then printed, along with a pedestal, to “float” above the “flowers”.

This was taken at the Friday night game with her friend… whose corsage was also crafted by my grand-daughter. Hmmm… hers is not as big? Face-painting by her Dad. And long gone are the days when the corsages were smaller and could be pinned on the shoulder of the dress… er, t-shirt.

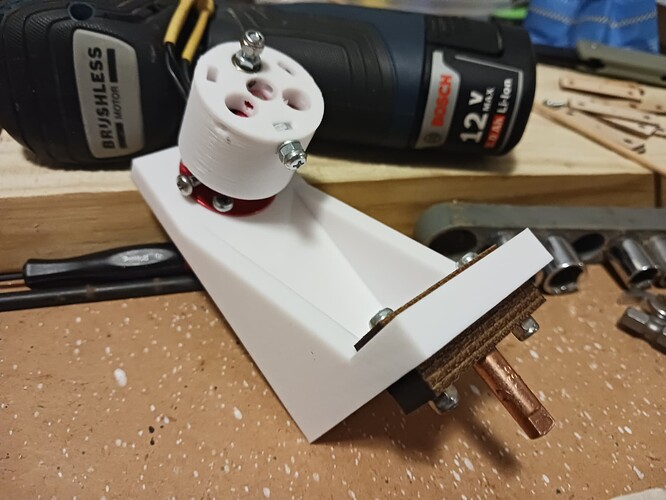

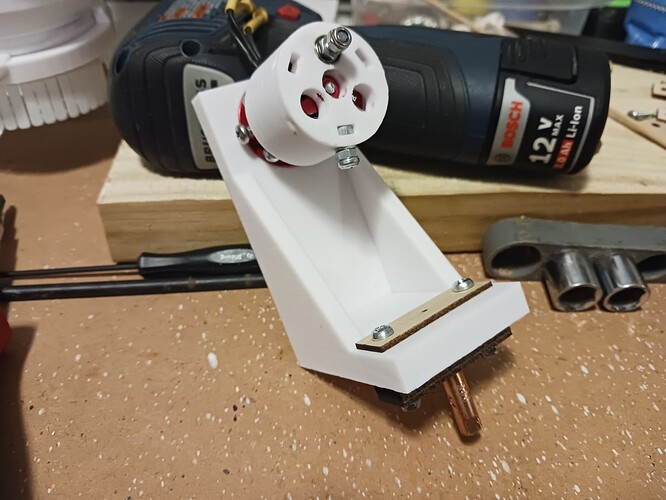

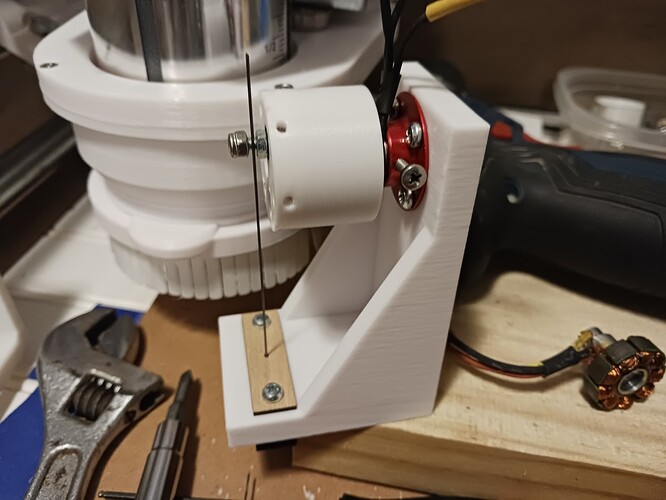

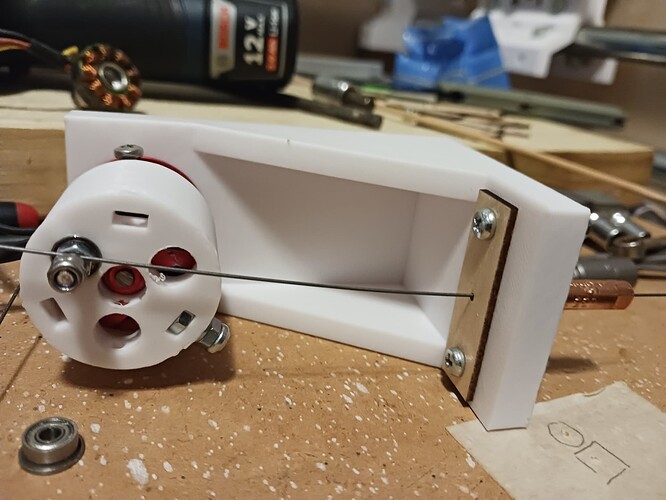

And “officially” I guess I’m currently working on yet another needle cutter… for MPR&P.

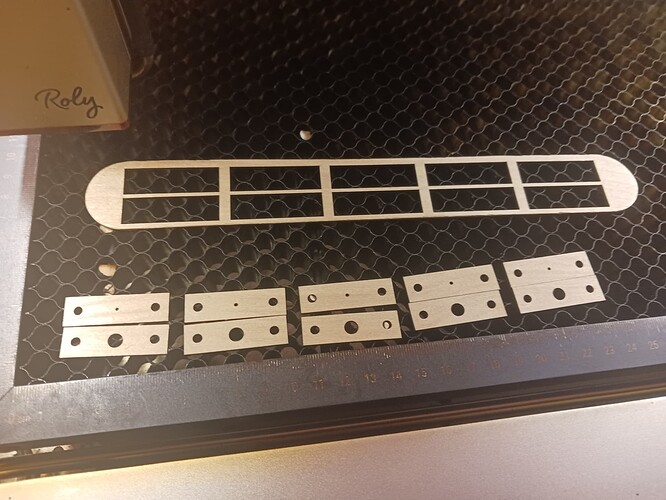

Laser-cutting the wooden “preguide” (small center hole) and main guide “stack” from a jumbo craft stick…

and then “borrowing” a 8mm OD x 3mm ID bearing from a junked motor… forgot photo and show flanged bearing that would also work.

and un-photoed bearing press-fitted into a newly-printed “slip-on flywheel” and roughly static-balanced…

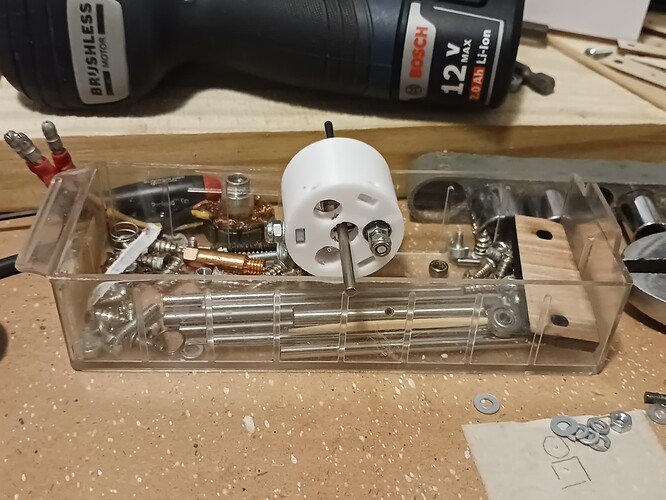

Needle-cutter assembly begins with flywheel slipped on…

and wooden guide stack and pre-guide installed…

A short length of 0.025" K&S music-/piano-wire to aid with rough alignment…

and all that’s left is to create a needle with a ~3mm loop to attach to “flywheel”. And, silly me, figure out how to mount it on MPR&P!

– David

Plus share some of the best plans sources for your foamie planes.

Any gliders? Manual kind that would be good for handouts/demos?

This is totally a tool build. I don’t intend to get back into building planes. I figure it’s just another tool to put on the MPR&P. I’ll try to demo what’s involved in putting a needle-cutter together but that’s the extent and end of my RC experience. I watched the video that @nstiesi shared above and it’s amazing how far the technology has come. If the electronics had been as advanced as that when my late fishing/flying buddy and I were fooling around with this stuff… even I might have actually had fun flying the fool things…

![]()

I really should get off my butt and make a needle cutter….or get a laser. One of the things I wanted a CNC for back when I built the MPCNC was for FliteTest plan part cutting. Templates and razor blades were getting taxing…..

Then, well, I slowly drifted away from the hobby. I tried to re-energize myself with a fully 3d printed build last year, and I didnt even finish that! The little gyro warbirds are all I seem to be able to find the time for.

This is an Eclipson design that I think I scaled down a bit to keep it compact. This was before I re-printed the tail section from LW-PLA (active foaming) as I couldn’t get the standard PLA to balance about the center of lift without a MASSIVE battery. The airframe is done but I never installed the electronics. I even bought a flight stabilizer for it but never got around to it. I’m sure its not very robust, but the idea of just 3d printing a plane or replacement parts whenever you need them sure is cool!

IMO the idea of just needle-cutting planes and replacement parts whenever you need them sure is also cool!

That’s actually what made the “demolition derby” style flying my buddy and I did in my pasture so much fun… last man standing… er, with enough “plane” left [after our hurried field repairs/surgeries…] to throw into the air and “fly”…wins! And then go home and cut a new plane/parts overnight, assemble, transfer electrics, and go fly some more!

I never did the 3d-print thing for RC… it was just becoming a thing toward the end of our flying days. It struck me at the time as being really slow [to print and build] and fragile. I can’t imagine multiple crashes and field repairs for a demolition session. And I’m afraid it would – for me – bring back the fear/apprehension of crashing. But with the advent of stabilized flight controllers like those now found in the little warbirds… I can see how that just might bring a lot more fun to actually flying for me. It is interesting!

But, sadly, a LACK OF MOTIVATION is increasingly an issue for me. I seem to rapidly tire and lose interest once the initial excitement of a project starts to wane.

could a needle cutter be designed such that it is driven by an existing spindle? That would be best case scenario where it just bolts on the spindle frame and is driven by a linkage through the spindle itself.

Its kind of a dumb question, as I know almost anything is possible with enough engineering effort and money…..just asking rhetorically.